Copper electroplating composition and method of filling cavities in semiconductor substrates using same

A composition and semiconductor technology, applied in the direction of semiconductor devices, semiconductor/solid-state device manufacturing, circuits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

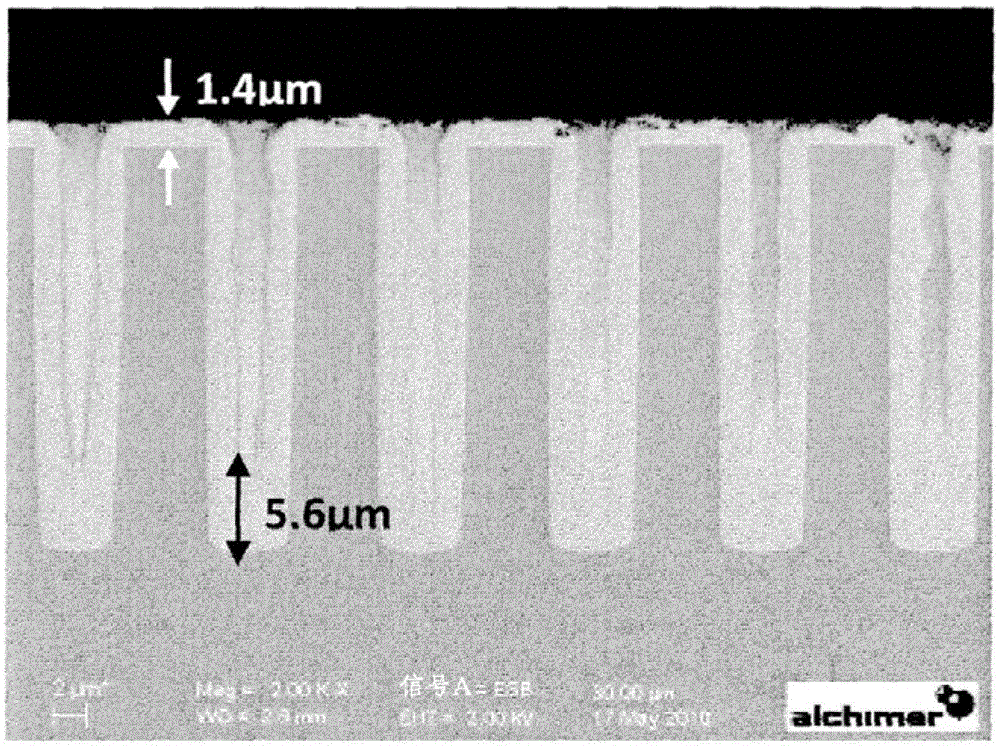

[0110] Example 1: Partial filling of holes with copper on a tantalum based barrier layer on which a copper seed layer has been deposited using an ethylenediamine-copper complex based composition according to the invention

[0111] A. Materials and equipment

[0112] Substrate:

[0113] The substrate used in this example was made of a 750 μm thick, 4 cm x 4 cm silicon wafer etched with a “through-hole” type cylindrical pattern with a depth of 25 μm and a diameter of 5 μm.

[0114] These patterns are covered with a 400nm thick layer of silicon dioxide, itself coated with a tantalum-based layer deposited by sputtering PVD (Physical Vapor Deposition), which is divided into two sublayers: the tantalum nitride sublayer layer (15nm) and tantalum sublayer (10nm).

[0115] This TaN / Ta "double layer" forms a copper diffusion barrier, such as is used in so-called "via" structures in integrated circuit fabrication.

[0116] A conformal copper seed layer with a thickness of about 200 nm...

Embodiment 2

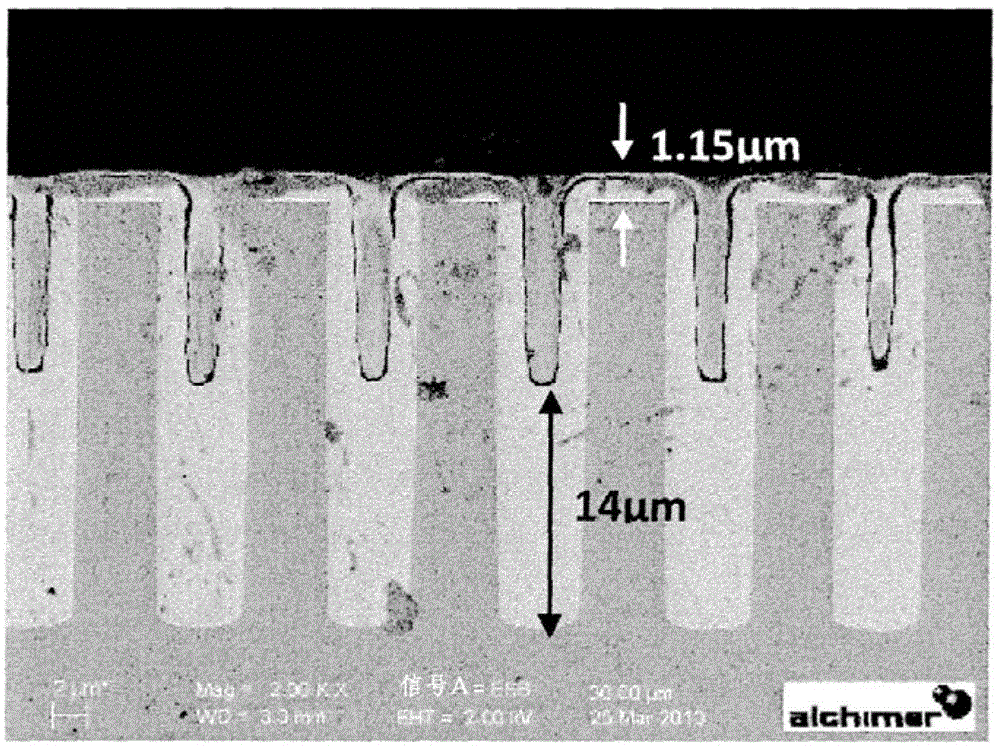

[0149] Example 2: Partial filling of holes with copper on a tantalum based barrier layer on which a copper seed layer has been deposited using an ethylenediamine-copper complex based composition according to the invention

[0150] A. Materials and equipment

[0151] Substrate:

[0152] The substrate used in this example is the same as that in Example 1.

[0153] Fill solution:

[0154] The solution used in this example is the same as that in Example 1.

[0155] equipment:

[0156] An electrowinning apparatus similar to fountain cells used in the microelectronics industry was used in this example.

[0157] An electrowinning cell contains an anode, which can be made of an inert metal such as platinum-coated titanium, or the same metal as the metal being deposited (copper in this case). A silicon wafer coated with a TaN / Ta barrier layer, itself coated with a copper seed layer, formed the cathode of the deposition cell.

Embodiment 4

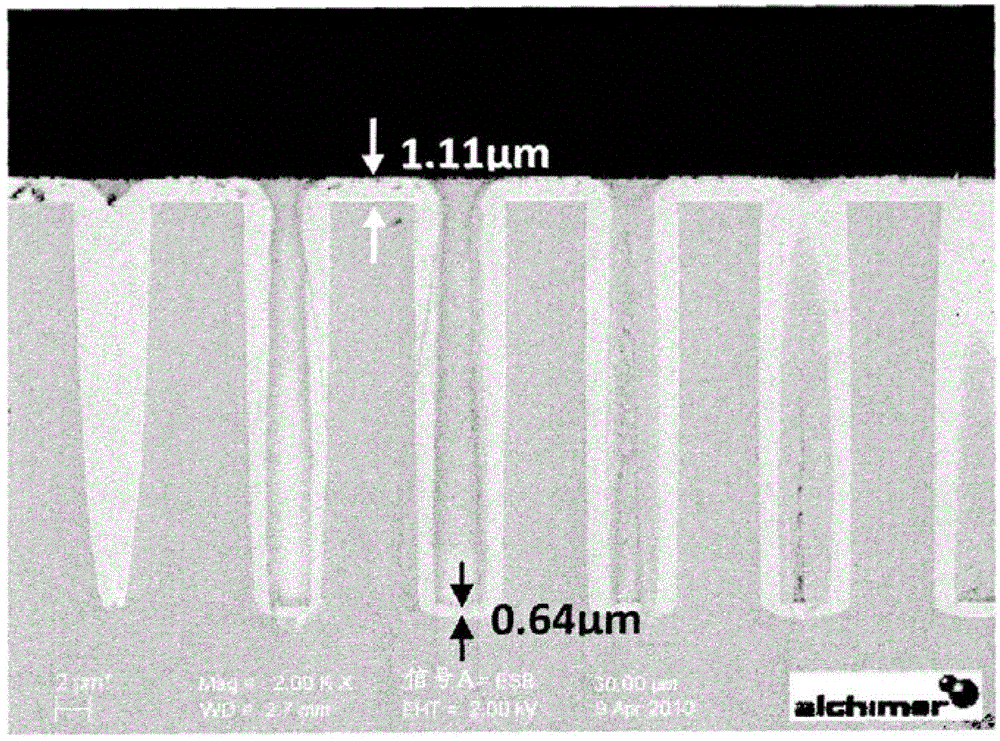

[0189] Example 4: Pore filling with copper on a nickel-based (NiB) barrier layer using an ethylenediamine-copper complex based composition according to the invention

[0190] A. Materials and equipment

[0191] Substrate:

[0192] The substrate used in this example consisted of a 750 μm thick, 4 cm x 4 cm doped (p-type) silicon wafer etched with “through hole” type cylindrical patterns of three different sizes:

[0193] - 25 μm in depth and 7 μm in diameter;

[0194] - 27 μm in depth and 9 μm in diameter; and

[0195] - 28 μm in depth and 11 μm in diameter.

[0196] Using the method described in document WO2010 / 001054, a 50 nm thick conformal NiB layer was deposited on the substrate surface, which layer formed a barrier to copper diffusion.

[0197] Fill solution:

[0198] The solution used in this example is the same as that in Example 1.

[0199] equipment:

[0200] The equipment used in this example is the same as that in Example 2.

[0201] B. Experimental method ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com