A method for manufacturing safe fire-resistant medium and high voltage cables

A technology for medium and high voltage cables and manufacturing methods, which are applied in the manufacture of cables/conductors, power cables with shielding layers/conducting layers, circuits, etc., can solve the problems of not being able to save time for rescue work, too simple structure, and poor heat insulation effect. , to achieve the effect of round shape, enhanced mechanical strength, and improved electrical insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

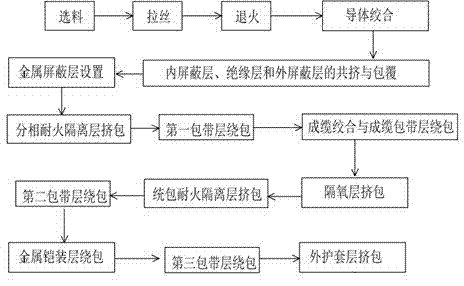

Embodiment 1

[0034] A method for manufacturing a safe fire-resistant medium and high voltage cable, comprising the following steps: material selection → wire drawing → annealing → conductor stranding → co-extrusion and covering of inner shielding layer, insulating layer and outer shielding layer → metal shielding layer setting → phase separation Extrusion of refractory insulation layer→wrapping of first tape layer→cable twisting and wrapping of cabled tape layer→extrusion of oxygen barrier layer→wrapping of refractory insulation layer→wrapping of second tape layer→metal Wrapping of the armor layer→wrapping of the third tape layer→extrusion of the outer sheath layer. The step of extruding the phase-separated refractory isolation layer refers to using a silicone rubber extruder to extrude the vitrified silicone rubber material on the metal shielding layer. On layer 5, the extrusion thickness is 2.0mm; the oxygen barrier layer extrusion step refers to the use of extrusion molds on the extrusio...

Embodiment 2

[0043] A method for manufacturing a safe fire-resistant medium and high voltage cable, comprising the following steps: material selection → wire drawing → annealing → conductor stranding → co-extrusion and covering of inner shielding layer, insulating layer and outer shielding layer → metal shielding layer setting → phase separation Extrusion of refractory insulation layer→wrapping of first tape layer→cable twisting and wrapping of cabled tape layer→extrusion of oxygen barrier layer→wrapping of refractory insulation layer→wrapping of second tape layer→metal Wrapping of the armor layer→wrapping of the third tape layer→extrusion of the outer sheath layer→performance inspection experiment→packaging of the finished product into storage. Silicone rubber material is extruded on the metal shielding layer, and the extruded thickness is 3.0mm; the step of extruding the oxygen barrier layer refers to using an extruding mold on the extrusion equipment, and using a screw with a compression...

Embodiment 3

[0054] A method for manufacturing a safe fire-resistant medium and high voltage cable, comprising the following steps: material selection → wire drawing → annealing → conductor stranding → co-extrusion and covering of inner shielding layer, insulating layer and outer shielding layer → metal shielding layer setting → phase separation Extrusion of refractory insulation layer→wrapping of first tape layer→cable twisting and wrapping of cabled tape layer→extrusion of oxygen barrier layer→wrapping of refractory insulation layer→wrapping of second tape layer→metal Wrapping of the armor layer→wrapping of the third tape layer→extrusion of the outer sheath layer→performance inspection experiment→packaging of the finished product into storage. Silicone rubber material is extruded on the metal shielding layer, and the extruded thickness is 4.0mm; the step of extruding the oxygen barrier layer refers to using an extrusion mold on the extrusion equipment, and using a screw with a compression...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com