Oil-immersed capacitive voltage divider

A capacitive voltage divider, oil-immersed technology, applied in the direction of voltage divider, can solve the problems of easy generation of parasitic coupling, uneven electric field, increase in volume, etc., and achieve the effect of reducing interference, high precision and small error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

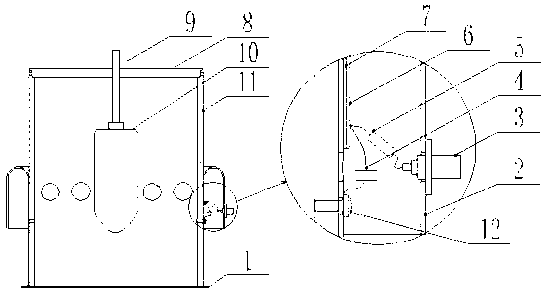

[0011] Such as figure 1 As shown, an oil-immersed capacitive voltage divider includes a box body, a cover plate 8, a base plate 1, and an insulating shell 11 arranged on the base plate 1. The insulating shell 11 is provided with a shielding shell 2. The described The insulating shell 11 in the shielding shell 2 is provided with a capacitor plate 6, an insulating layer 7 is provided between the insulating shell 11 and the capacitor plate 6, and a BNC seat 3 is provided on the shielding shell 2, and the BNC seat 3 passes through the current limiting The protection resistor 5 is connected to the capacitor plate 6 , and the capacitor plate 6 is connected to the shielding shell 2 through the voltage dividing sampling capacitor 4 .

[0012] The voltage-dividing sampling capacitor 4 is susceptible to interference, and when it is disturbed, it has a great influence on the sampling signal, causing a large deviation between the sampling value and the actual value. Therefore, the shieldi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com