Photochromic microcapsule coating amount detection method

A photochromic and detection method technology, applied in the direction of color/spectral characteristic measurement, etc., can solve the problems of incompleteness, error, inaccurate detection results, etc., and achieve the effect of improving production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0034] Example: The colorimetric method is used to detect the coating amount of photochromic microcapsules (light reddening).

[0035] Main experimental instruments, materials and reagents: 722S visible spectrophotometer; photochromic core material, photochromic microcapsules, organic solvents.

[0036] Experimental steps:

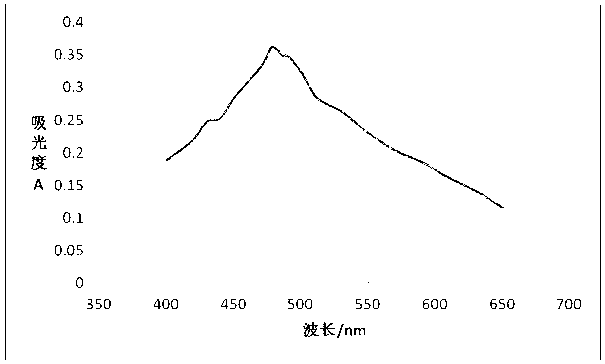

[0037] 1. Take 3-10 grams of the core material (light reddening), dissolve it in 50-100ml of organic solvent, and prepare the light reddening core material organic solution A, take 10 grams of the prepared core material organic solution A, and put The core material organic solution A is placed in a 722S visible spectrophotometer at room temperature to measure its maximum absorption wavelength, such as figure 1 As shown, the maximum absorption wavelength of the core material organic solution is 477nm. Then, the absorbance was measured at the maximum absorption wavelength of the core material organic solution A and marked as A0.

[0038] 2. Take 10-50 gra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com