Pressure sensor

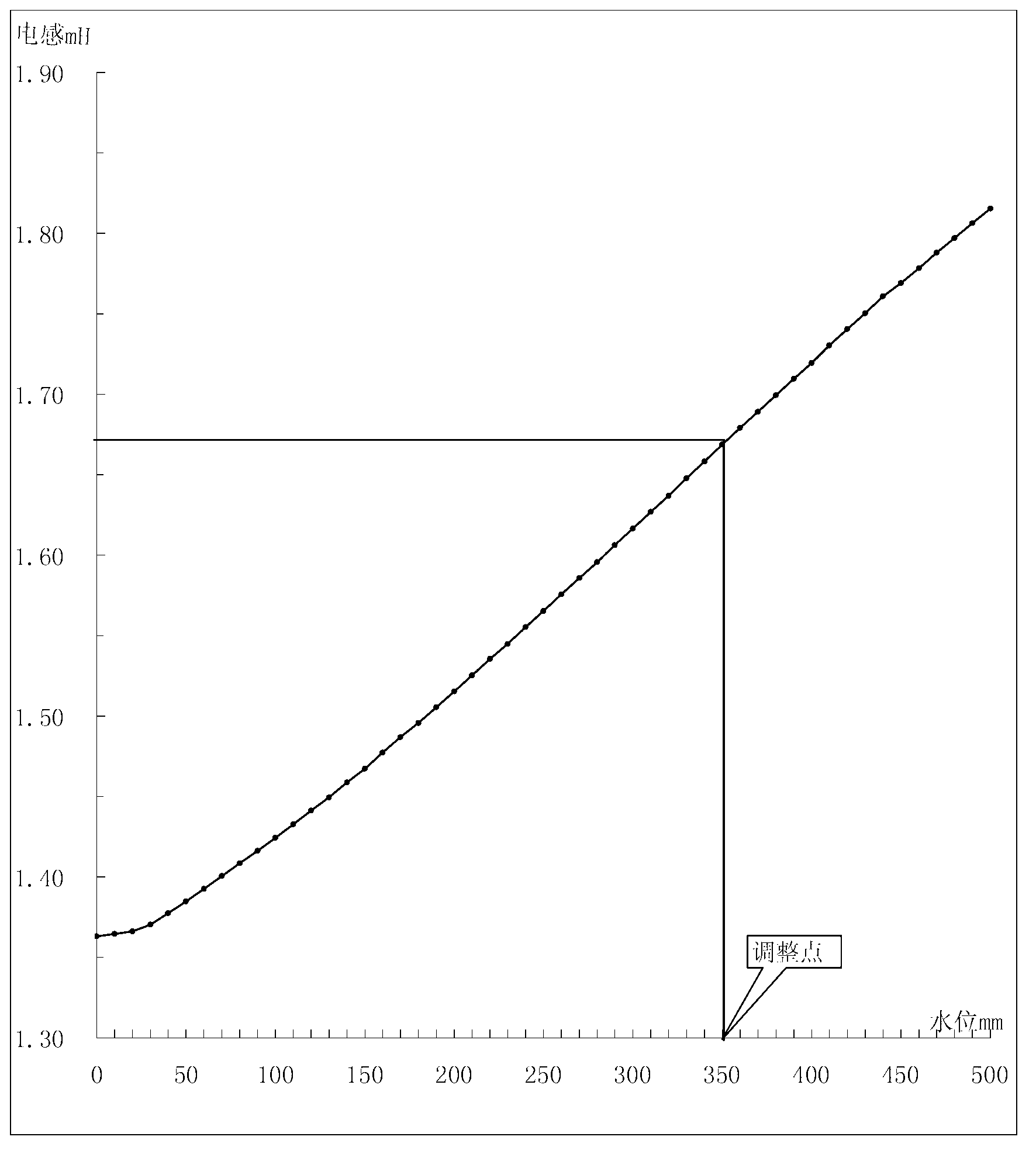

A pressure sensor and inductance coil technology, which is used in the measurement of fluid pressure, and the display of liquid level indicators and instruments through pressure measurement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

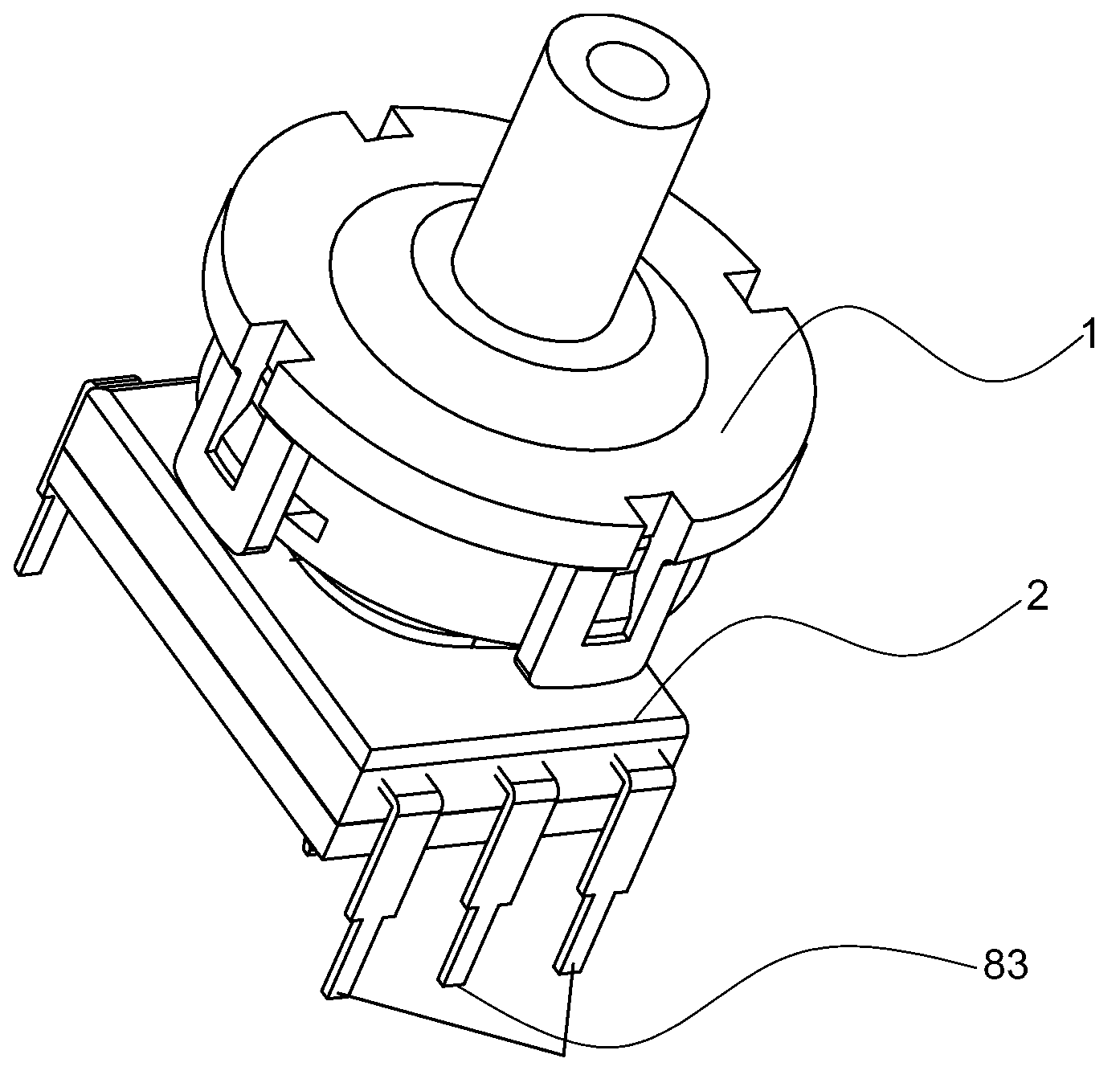

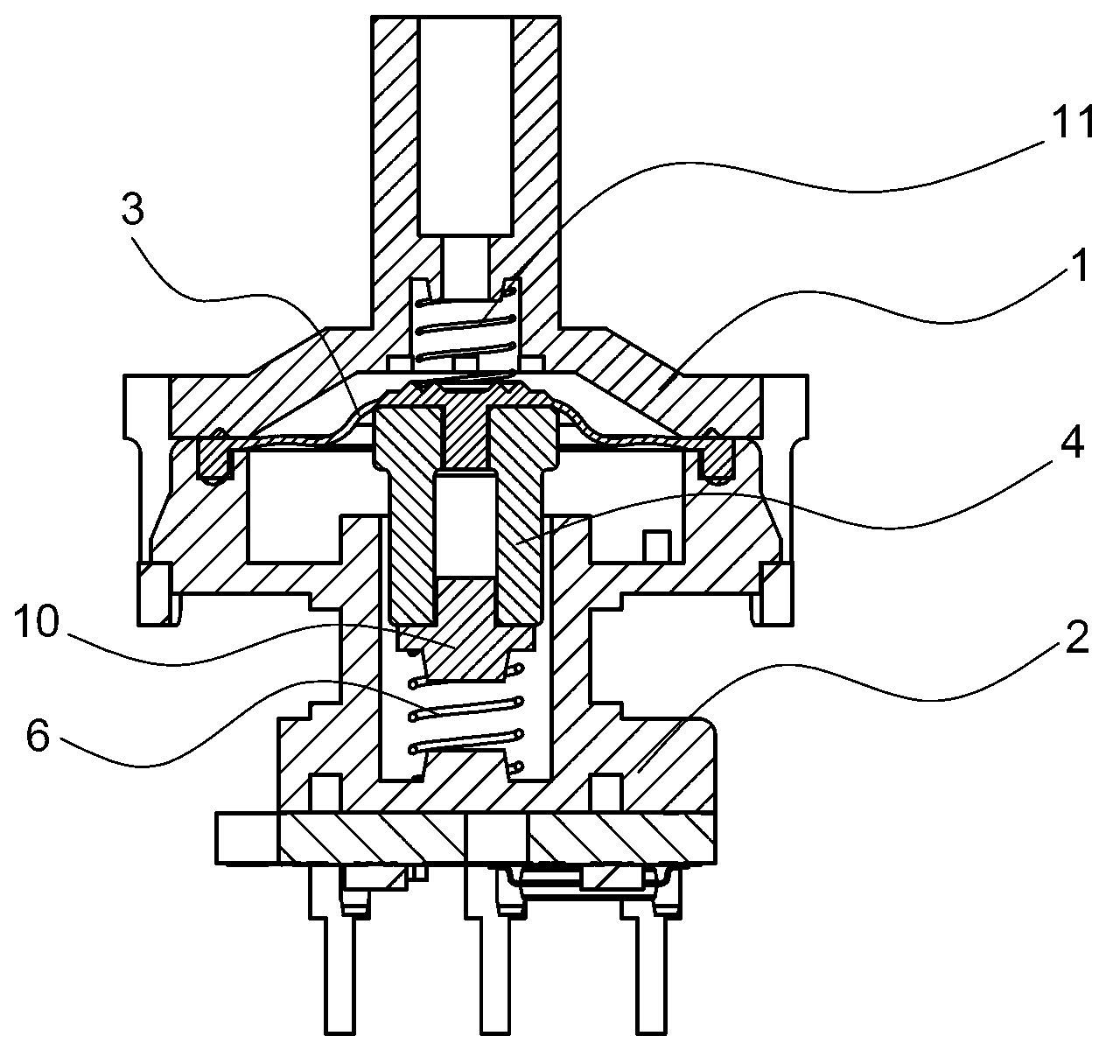

[0024] The pressure sensor of this embodiment includes a gas cover 1 and a housing 2. The housing has a skeleton around which coils are wound. An elastic diaphragm 3 is fixed at the junction of the elastic diaphragm, and an iron core 4 is embedded in the center of the elastic diaphragm. The iron core can move axially in the skeleton with the elastic diaphragm, and an inductor is wound on the skeleton of the housing. Coil 5, a spring 6 is installed between the lower end of the iron core and the bottom surface of the skeleton cavity of the housing, a circuit board 7 is connected under the housing, a memory device 71 is arranged on the circuit board, and a frequency signal output terminal is fixed on the housing 8 and the memory signal input and output terminal 9, one end 81 of the frequency signal output terminal and one end 91 of the memory signal input and output terminal output signals to the outside, the middle part 82 of the frequency information output terminal and the midd...

Embodiment 2

[0055] For the pressure sensor of this embodiment, see Figure 4 , Figure 7 , the elastic diaphragm is provided with a spring two 11 above, which can make the sensor start to record the curve when starting, and an iron core support 10 is housed between the iron core 4 and the spring one 6 . The other constructions are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com