Method for producing avilamycin by fermenting

An aviramycin and fermentation culture technology, applied in the field of industrial biotechnology, can solve the problems of unstable fermentation results, cumbersome seed production process, easy degradation of bacterial species, etc., to reduce the risk of infection, high biological activity, and promote The effect of animal growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

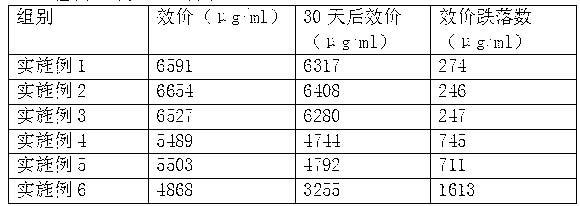

Examples

Embodiment 1

[0038] A method for producing avelamycin by fermentation, the technical scheme is as follows:

[0039] (1) Preparation of slanted spores

[0040] The MCCC1A01659-produced Streptomyces viridans purchased at Beijing Beina Chuanglian Biotechnology Research Institute, the strain preservation number is 1A01659, was inoculated into the slant medium, and the slant culture was carried out to obtain slant spores. The surface of the slant was full of off-white to slightly gray spores;

[0041] (2) Preparation of frozen seed solution:

[0042] a. Inoculate the above-mentioned slant spores into 100ml seed culture medium, the inoculum size is 0.2×10 7 1 spore, culture temperature 28 ℃, culture time 24h, obtain seed liquid, the solid matter in seed liquid accounts for 20%V / V of seed liquid total amount;

[0043] b. Add an equal volume mass fraction of 40% glycerol aqueous solution to the seed liquid obtained above, mix well to make a glycerin seed liquid, subpackage in cryopreservation tu...

Embodiment 2

[0051] A method for producing avelamycin by fermentation, the technical scheme is as follows:

[0052] (1) Preparation of slanted spores

[0053] The MCCC1A01659-produced Streptomyces viridans purchased at Beijing Beina Chuanglian Biotechnology Research Institute, the strain preservation number is 1A01659, was inoculated into the slant medium, and the slant culture was carried out to obtain slant spores. The surface of the slant was full of off-white to slightly gray spores;

[0054] (2) Preparation of frozen seed solution:

[0055] a. Inoculate the above-mentioned slant spores into 100ml seed culture medium, the inoculum size is 0.5×10 7 1 spore, culture temperature 28 ℃, culture time 30h, obtain seed liquid, the solid matter in seed liquid accounts for 25%V / V of seed liquid total amount;

[0056] b. Add an equal volume mass fraction of 40% glycerol aqueous solution to the seed liquid obtained above, mix well to make a glycerin seed liquid, subpackage in cryopreservation tube...

Embodiment 3

[0064] A method for producing avelamycin by fermentation, the technical scheme is as follows:

[0065] (1) Preparation of slanted spores

[0066] The MCCC1A01659-produced Streptomyces viridans purchased at Beijing Beina Chuanglian Biotechnology Research Institute, the strain preservation number is 1A01659, was inoculated into the slant medium, and the slant culture was carried out to obtain slant spores. The surface of the slant was full of off-white to slightly gray spores;

[0067] (2) Preparation of frozen seed solution:

[0068] a. Inoculate the above-mentioned slant spores into 100ml seed culture medium, the inoculum size is 0.8×10 7 1 spore, culture temperature 28 ℃, culture time 36h, obtain seed liquid, the solid matter in seed liquid accounts for 30%V / V of seed liquid total amount;

[0069] b. Add an equal volume mass fraction of 40% glycerol aqueous solution to the seed liquid obtained above, mix well to make a glycerin seed liquid, subpackage in cryopreservation tu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com