Three-dimensional curved surface processing apparatus for thick plate using high frequency induction heating by controlling automatic precise positioning of coil

A high-frequency induction coil and precision control technology, which is applied in the direction of manufacturing tools, heat treatment process control, and energy efficiency improvement. Effects of improving productivity and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

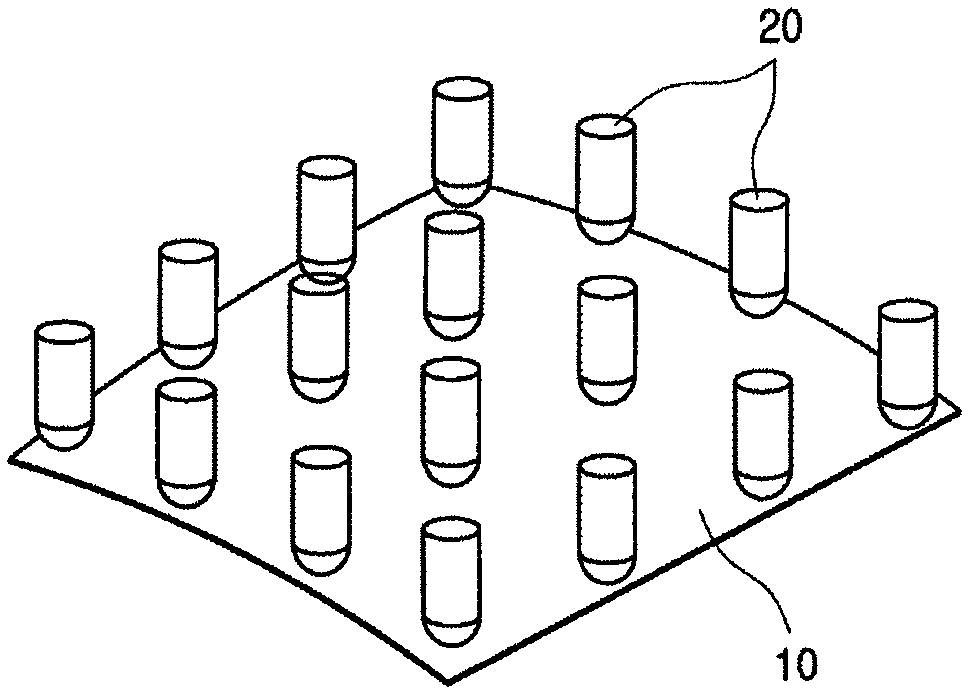

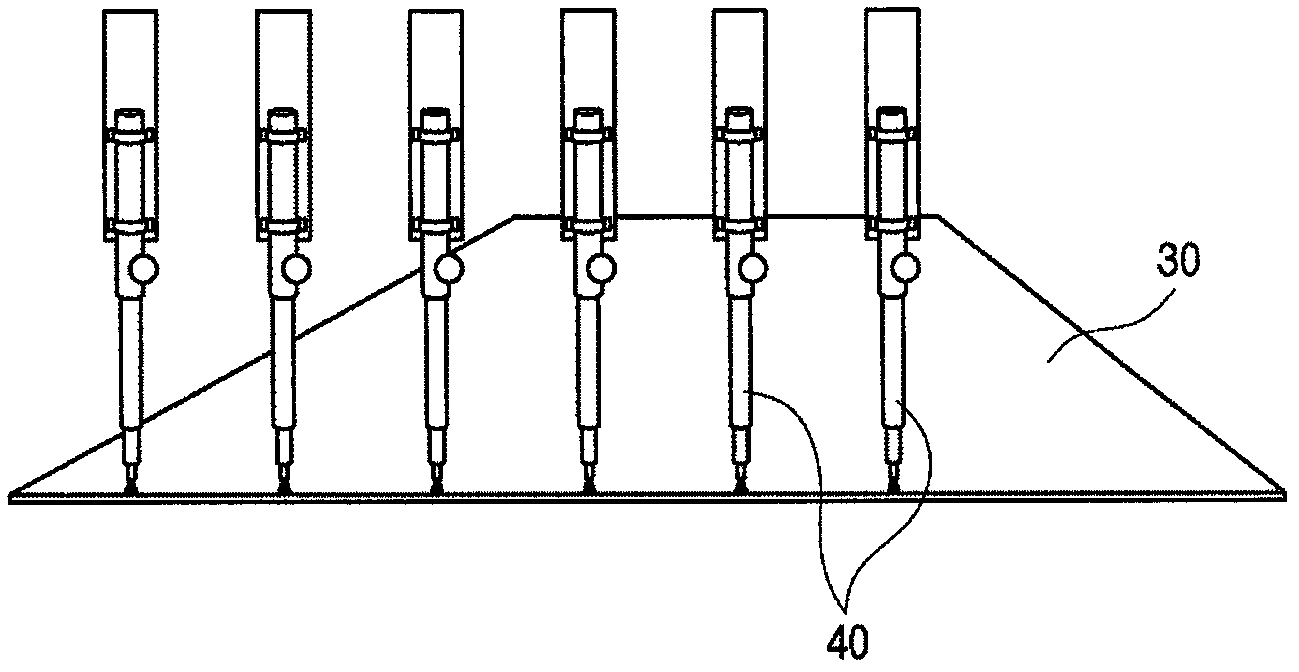

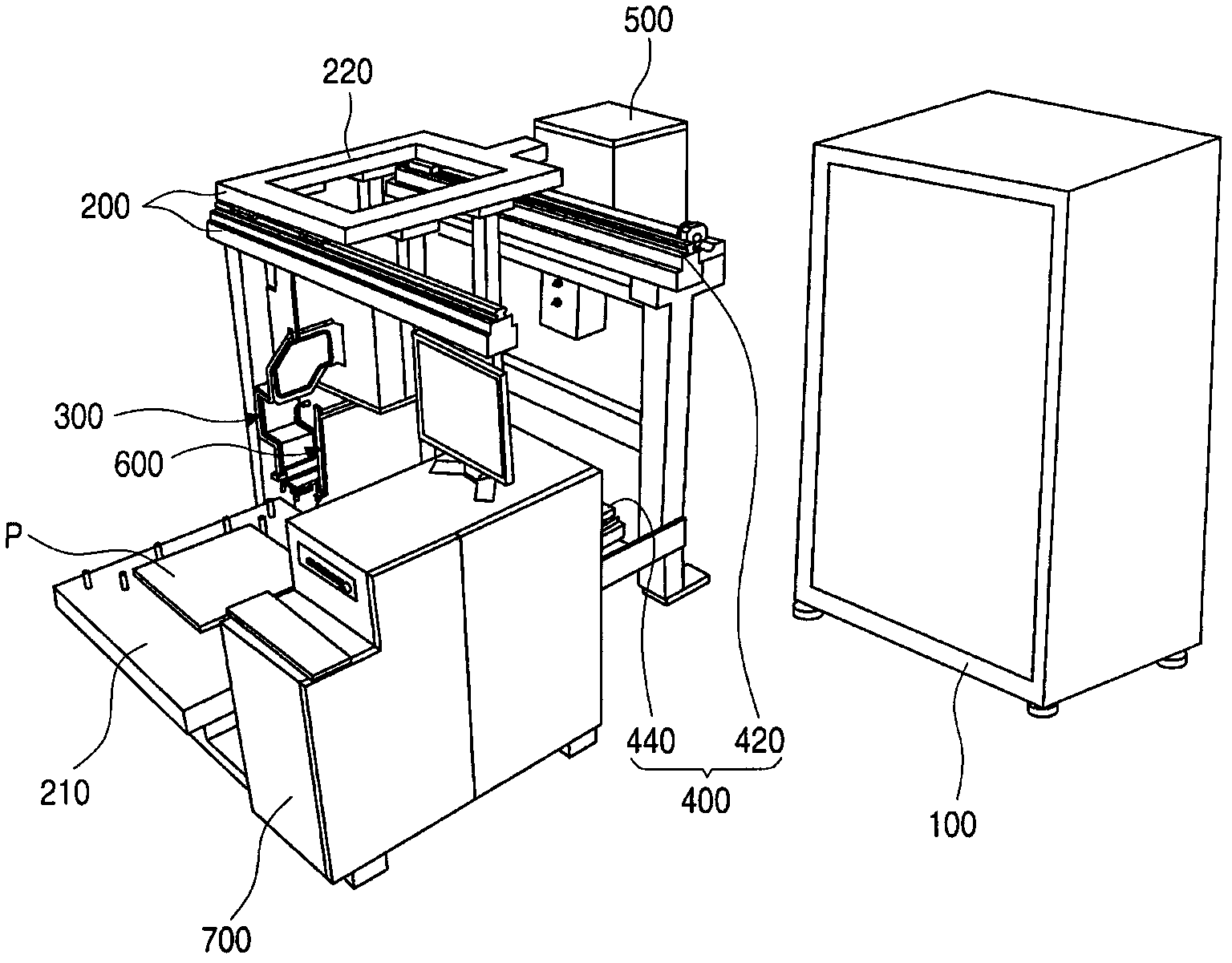

[0052] The following combination image 3 and Figure 4 , the structure of the thick plate three-dimensional curved surface processing device using high-frequency induction heating of the present invention will be described in detail.

[0053] The professional terms mentioned in this specification and claims are not limited to common understanding and dictionary interpretation, and the inventor selects appropriate words for expression in order to better illustrate the spirit and principles of the present invention. The embodiment of the present invention is only a preferred example for illustrating the present invention, and the present invention is not limited thereto, and various modifications and substitutions are possible within the spirit and principle of the present invention.

[0054] image 3 It is a perspective view of a thick plate three-dimensional curved surface processing device that automatically and precisely controls the position of a high-frequency induction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com