Wavelength tunable laser system and its control method

A technology for tuning lasers and control methods, applied in the field of lasers, can solve the problems of unavailable lasers and difficult to achieve real-time feedback control, etc., and achieve the effect of simple structure, small size and high control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

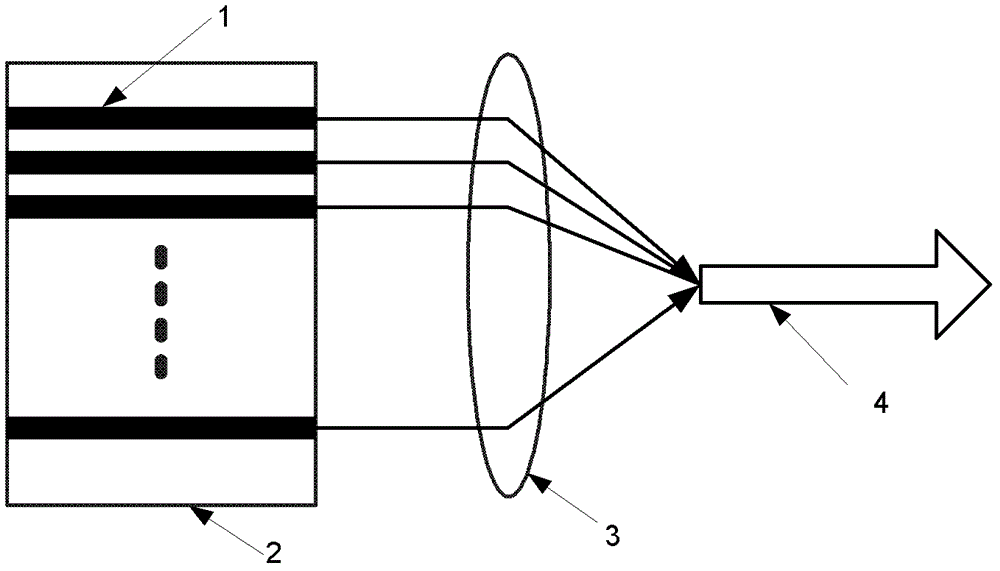

[0039] Such as figure 1 As shown, in this example, 20 DFB laser modules 1 are arranged in parallel on the same plane and in the same thermoelectric cooler (TEC), that is, A thermoelectric cooler 2 in the figure, and the laser beams generated by each DFB laser module 1 pass through the condenser lens 3 converging on the optical waveguide 4. This example is a one-dimensional DFB laser. A. The temperature range of the thermoelectric cooler 2 is 10-60°C. The wavelength adjustment range of the DFB laser in this example is 1525-1610 nm, with a total of 20 channels, and the wavelength interval of each channel is 4.5 nm.

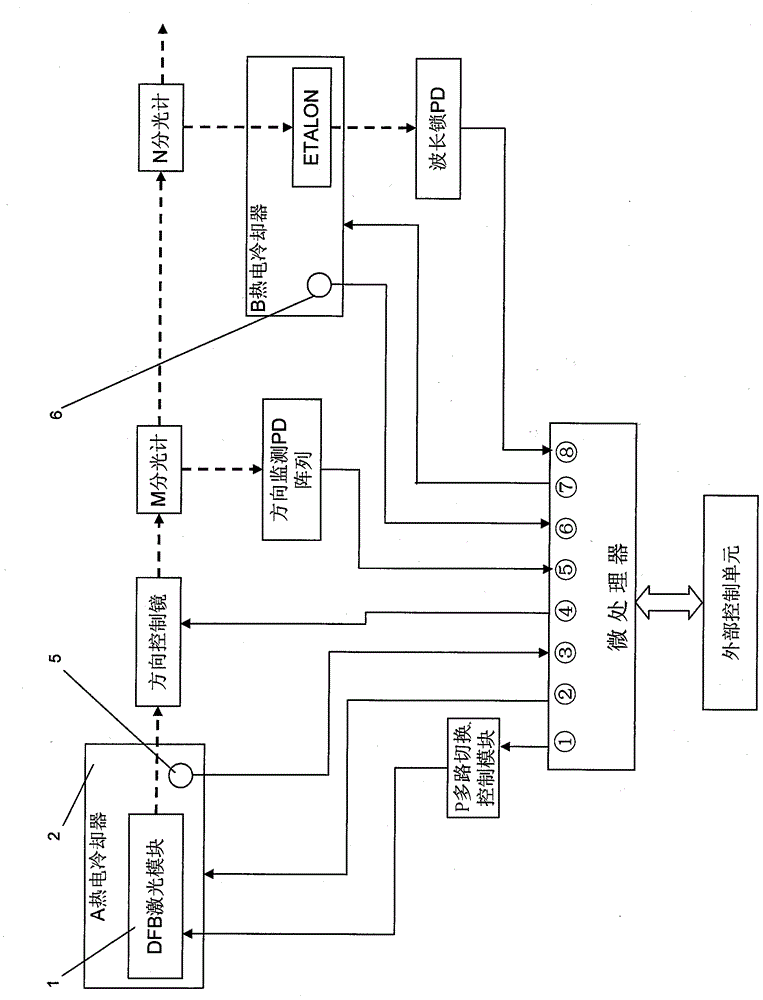

[0040] figure 2 Shown is the structure of the wavelength tunable laser system in this example, including microprocessor, DFB laser, A thermoelectric cooler and A temperature sensor installed on it, M spectrometer, N spectrometer, direction monitoring photodiode array (direction monitoring PD array), B thermoelectric cooler and Etalon and B temperature sensors in...

Embodiment 2

[0055] The DFB laser used in this example is also a one-dimensional DFB laser, such as Figure 5 As shown, 10 DFB laser modules 1 are fan-shaped and arranged on the same plane on the same A thermoelectric cooler 2, and the extension lines of the center lines of each DFB laser module 1 intersect at one point, that is, the laser light generated by them directly converges on the optical waveguide 4 .

[0056] Other structures are the same as in Embodiment 1.

[0057] Its method of use is the same as in Example 1.

[0058] The output laser beam produced by the wavelength tunable laser system and its control method in this example has a wavelength range of 1525-1568nm, covering the entire communication wavelength of the C-band, and the tuning accuracy is up to 1pm.

Embodiment 3

[0060] The DFB laser used in this example is as Figure 6 As shown, 10 DFB laser modules 1 are parallel and side by side on the same plane, and the laser beams generated by each DFB laser module 1 are converged on the optical waveguide 4 through the condenser lens 3 to form a DFB laser module array. Two identical DFB laser module arrays are each placed in one A thermoelectric cooler 2, the two A thermoelectric coolers 2 are parallel and side by side, and the two optical waveguides are combined into one to form a grouped two-dimensional DFB laser.

[0061] The structure of the wavelength tunable laser system in this example is as follows Figure 7 As shown, its optical path and circuit are similar to Embodiment 1. The two DFB laser module arrays are respectively located on the two A thermoelectric coolers, and each of the two A thermoelectric coolers is equipped with an A temperature sensor. The first output terminal of the microprocessor is respectively connected to control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com