Continuously variable transmission devices

A technology of continuously variable transmission and variable speed transmission, which is applied in belts/chains/gears, mechanical equipment, transmission devices, etc. It can solve the problems of power reduction, poor resistance to overload and impact resistance, and low load-carrying capacity, so as to achieve stable output power, The effect of wide speed range and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

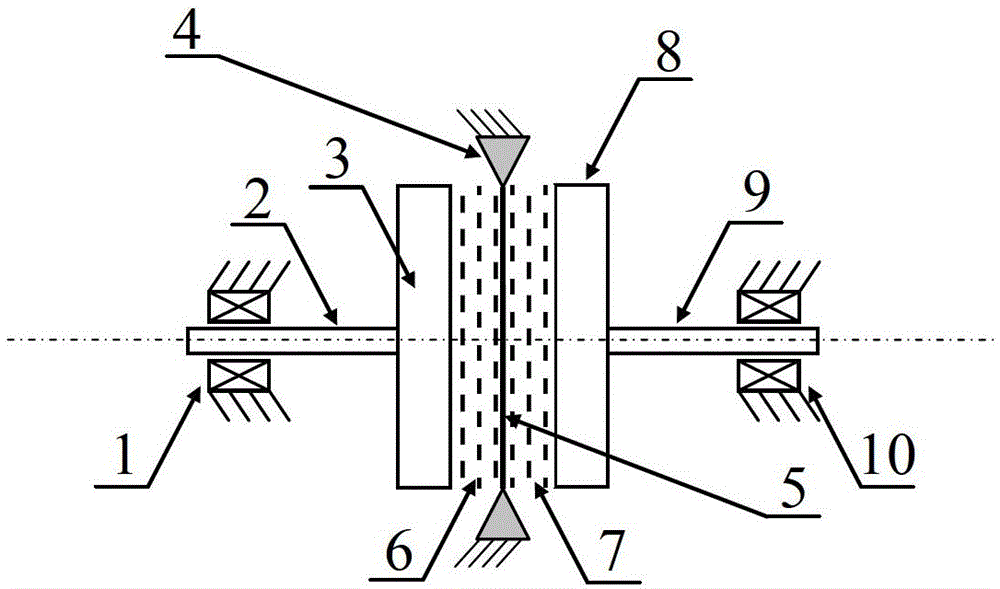

Embodiment 1

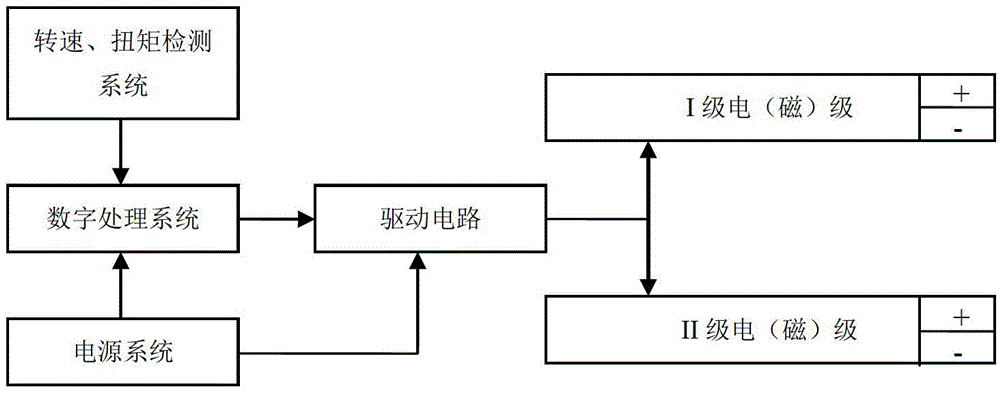

[0042] like figure 1 shown. A continuously variable transmission, comprising an input system, a variable speed transmission system and an output system arranged in series coaxially; The system includes an elastic mechanism 4, a transmission disc 5, a class I medium 6 and a class II medium 7, wherein the class I medium 6 and the class II medium 7 are electrorheological fluids; the output system includes a class II energy storage flywheel 8, an output shaft 9 and the output shaft locating bearing 10; the input shaft locating bearing 1 is embedded with the input shaft 2 to fix the input shaft 2, and the input shaft 2 is coaxially rigidly connected with the heavy I-level energy storage flywheel 3; the I-level energy storage A class I medium 6 is placed between the flywheel 3 and the drive disc 5, and a class II medium 7 is placed between the drive disc 5 and the class II energy storage flywheel 8; Under the action of the solid-liquid transition medium, when a voltage or magnetic...

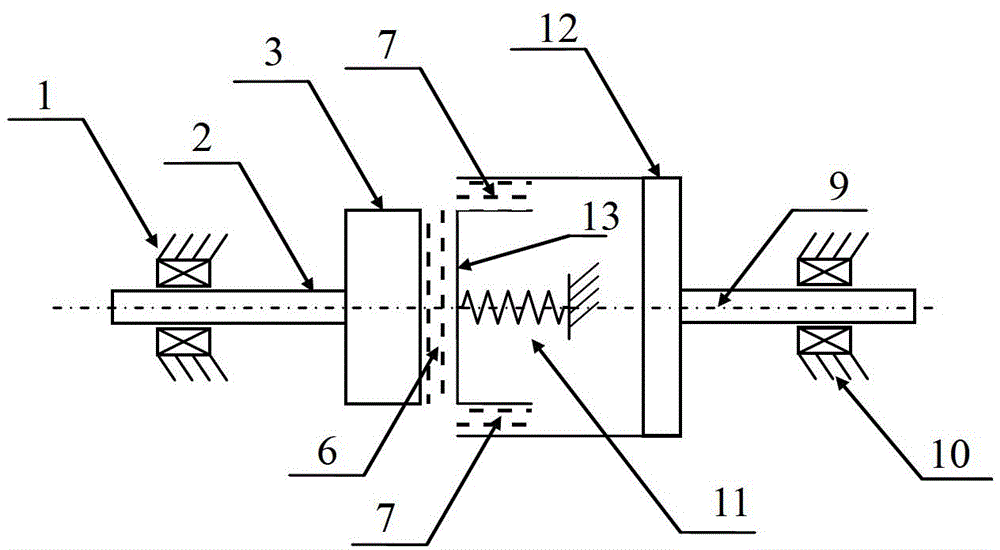

Embodiment 2

[0051] Level I medium 6 and level II medium 7 are electromagnetic fluids, and the others are the same as in Embodiment 1. The surfaces of the I-level energy storage flywheel 3, the II-level energy storage flywheel 8 and the transmission disc 5 are subjected to magnetic isolation treatment.

Embodiment 3

[0053] Level I medium 6 and level II medium 7 are controllable magnetic powders, and the others are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com