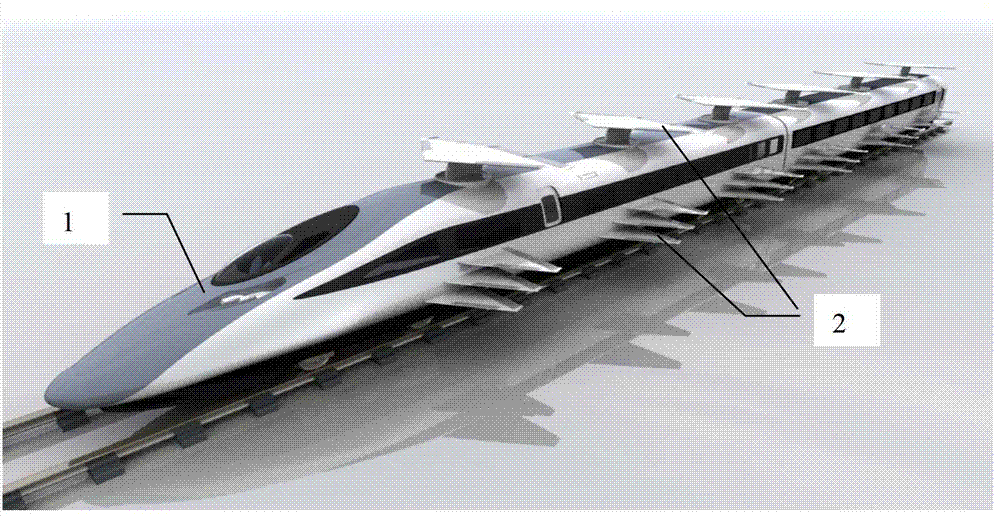

Composite material platform floor with netty three-dimensional whole multidirectional linking and weaving structure and preparation method of the composite material platform floor

A technology for car floor and composite material, applied in braid, fabric, textile and other directions, can solve the problems of poor bending resistance, torsion resistance and impact resistance, low in-plane shear performance, and increased fiber volume content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

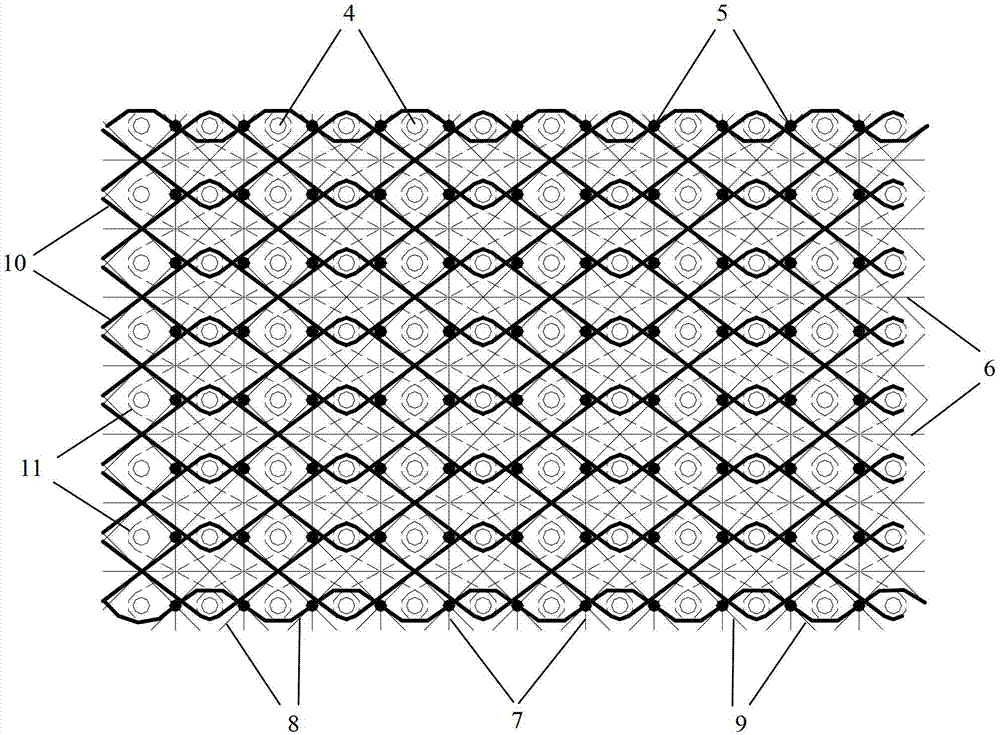

Embodiment 1

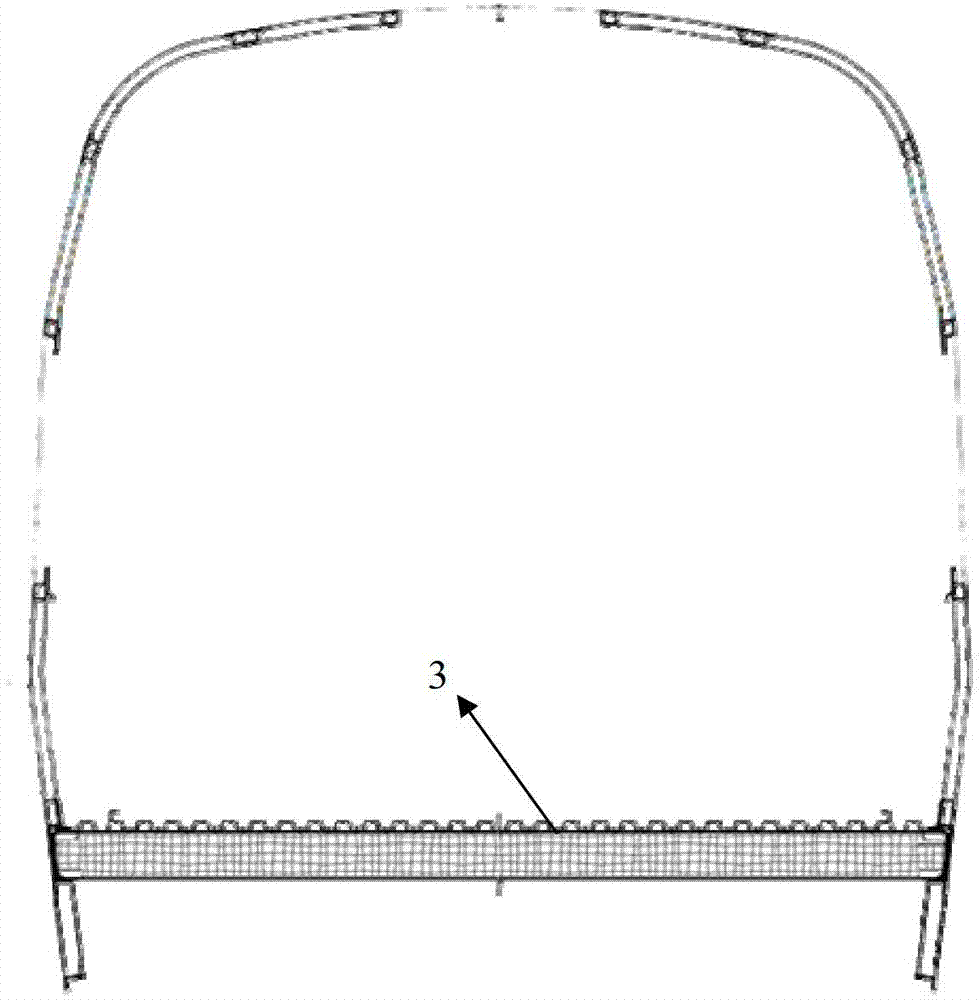

[0107] The cross-section of the preformed part of the composite material carriage floor is square, and the external dimensions are: 25 meters (length) × 3 meters (width) × 0.03 meters (height).

[0108] 1) Design of preformed parts

[0109] a) determine the yarn raw material;

[0110] The raw material for all yarn systems is yarn bundles composed of glass fibres.

[0111] b) Determine the number of yarn carriers on the chassis of the knitting machine;

[0112] The number of rows of the main body yarn carrier is m=12, the number of columns of the main body yarn carrier is n=90, and the ratio of the braiding yarn system to the shaft yarn system is 1:1, that is, the shaft yarn is fully loaded.

[0113] Number of knitting yarn carriers: 12 rows x 900 columns = 10800

[0114] Number of shaft yarn carriers: 12 rows x 900 columns = 10800

[0115] c) Determine braiding angle, fiber volume content, flower node length;

[0116] The braiding angle is 20 degrees, the fiber volume conte...

Embodiment 2

[0162] The cross-section of the preformed part of the composite material compartment floor is square, and the external dimensions are: 25 meters (length) × 3 meters (width) × 0.05 meters (height).

[0163] 1) Design of preformed parts

[0164] a) determine the yarn raw material;

[0165] Weaving yarn system, shaft yarn system, horizontal filling weft system, longitudinal filling weft system, +45 degree filling weft system, -45 degree filling weft system, horizontal interweaving weft system, and longitudinal interweaving weft system all use T300 12k carbon fiber.

[0166] b) Determine the number of yarn carriers on the chassis of the knitting machine;

[0167] The number of rows of the main body yarn carrier is m=20, the number of columns of the main body yarn carrier is n=1000, and the ratio of the braiding yarn system and the shaft yarn system is 1:1, that is: full loading of shaft yarns.

[0168] Number of knitting yarn carriers: 20 rows x 1000 columns = 20000 pieces

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com