Tough inorganic baked-porcelain paint

A coating and porcelain baking technology, applied in the field of baking varnish coatings, can solve the problems of no advection time, high energy consumption, and excessive gelation of coatings, and achieve the effects of preventing excessive gelation, low energy consumption, and preventing loss of gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

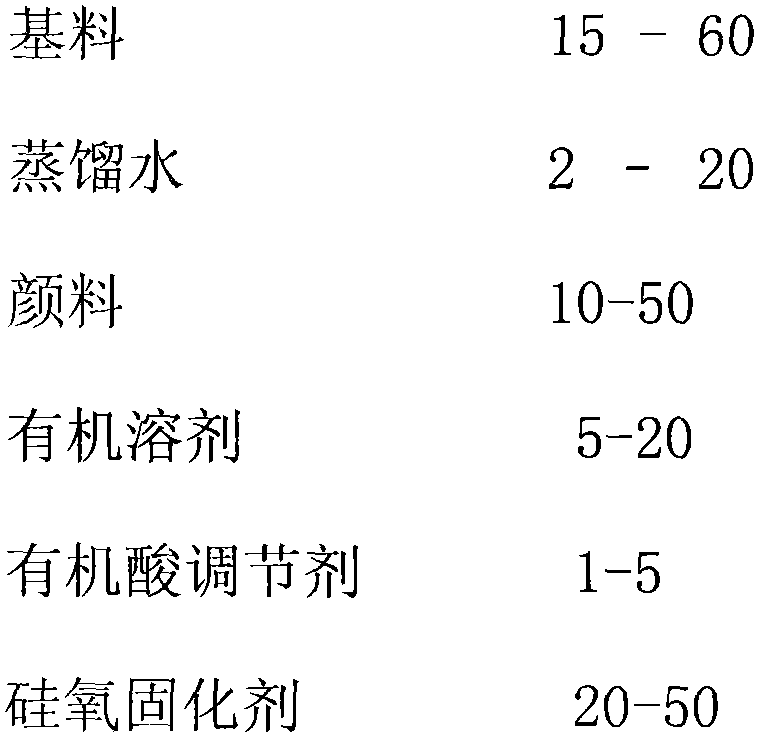

[0029] A tough inorganic ceramic coating comprising the following components:

[0030]

[0031] The preparation method of ceramic coating as above, comprises the following steps:

[0032] 1. Paint preparation: Add the weighed and measured components in the ceramic pot in sequence, stir at high speed for 3 hours, pour it out and mature for 3 hours, and filter it with a filter of 120 mesh or above for later use.

[0033] 2. Surface treatment of the workpiece: degrease the surface of the workpiece and then perform sandblasting treatment, and clean the workpiece. The workpiece must be sprayed within 24 hours after sandblasting.

[0034] 3. Construction: Adjust the pressure of the spray gun between 0.4-0.8Mpa; control the thickness of the paint film between 25um-35um, and control the viscosity of the paint during spraying between -4 cups and 11-20 seconds. Ethanol or acetone can be used for viscosity adjustment.

[0035] 4. Curing: curing under the condition of 0-185 degrees, t...

Embodiment 2

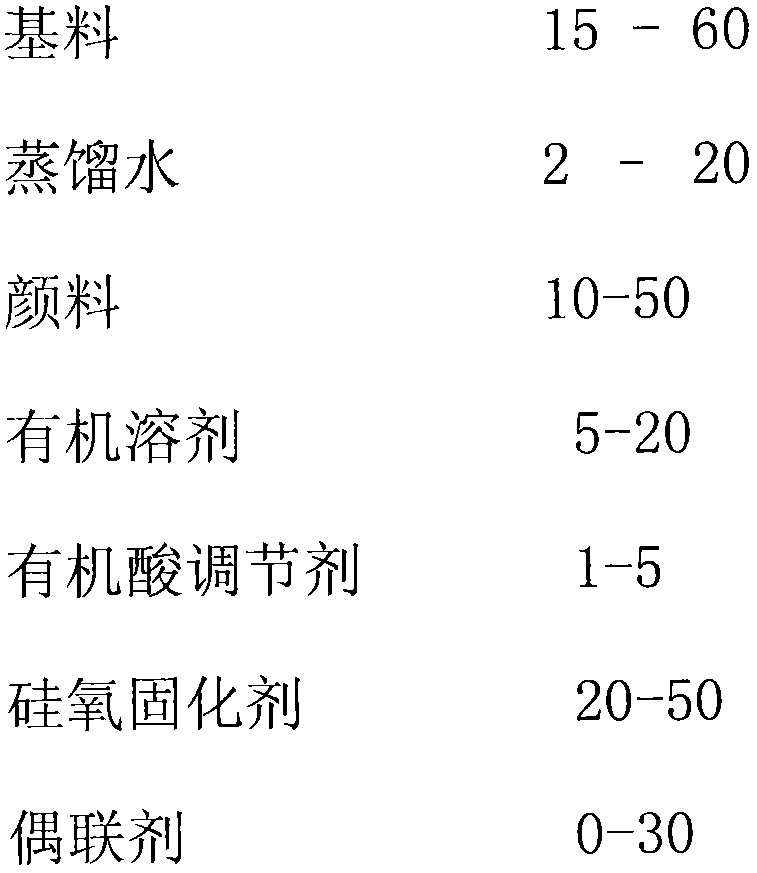

[0042] A tough inorganic ceramic coating comprising the following components:

[0043]

[0044]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com