Diisocyanate having fluorine-containing branched chain, preparation method and application thereof

A diisocyanate and side chain technology, applied in the application field of water-based fluorine-containing polyurethane, can solve the problems of slow reaction, poor reactivity, and limitation of practical application, and achieve the effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A side chain fluorine-containing diisocyanate, calculated in parts by weight, its raw material composition and content are as follows:

[0043] 6 parts trimethylolpropane

[0044] Isophorone diisocyanate 100 parts

[0045] 2,2,2-Trifluoroethanol 5 parts

[0046] Catalyst 0.06 parts

[0047] Wherein said catalyst is stannous octoate.

[0048] The preparation method of the above-mentioned side chain fluorine-containing diisocyanate, the steps are as follows:

[0049] Stir and dehydrate 6 parts of trimethylolpropane at 110°C and a vacuum of 750mmHg for 0.5h, add 100 parts of isophorone diisocyanate and 0.03 parts of stannous octoate under nitrogen protection, react at 80°C for 2h, add 5 parts of 2 , 2,2-Trifluoroethanol and the remaining stannous octoate, continue to react at 80°C for 3h to obtain a light yellow viscous side chain fluorine-containing diisocyanate.

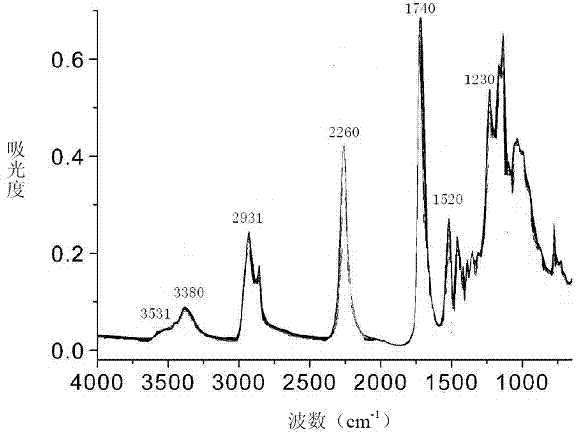

[0050] The side chain fluorine-containing diisocyanate of above-mentioned gained carries out infrared s...

Embodiment 2

[0077] A side chain fluorine-containing diisocyanate, calculated in parts by weight, its raw material composition and content are as follows:

[0078] Trimethylolpropane 10 parts

[0079] Isophorone diisocyanate 120 parts

[0080] 2,2,2-Trifluoroethanol 10 parts

[0081] Catalyst 1.8 parts

[0082] The catalyst described therein is a mixture of dibutyltin dilaurate and triethylamine in a mass ratio of 1:1.

[0083] The preparation method of the above-mentioned side chain fluorine-containing diisocyanate, the steps are as follows:

[0084] Stir and dehydrate 10 parts of trimethylolpropane at 110°C and a vacuum of 720mmHg for 1 hour, add 120 parts of isophorone diisocyanate and 0.9 parts of catalyst under nitrogen protection, react at 85°C for 2.5 hours, add 10 parts of 2,2 , 2-trifluoroethanol and the remaining catalyst, continue to react at 85°C for 2h, and obtain a water-white viscous side chain fluorine-containing diisocyanate.

[0085] A kind of aqueous fluorine-contai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com