Vitrified ceramic tile blank and vitrified ceramic tile preparation method thereof

A technology for vitrified ceramic tiles and blanks, which is applied in the field of ceramic processing and can solve the problems of easy cracking, stuck kiln accident, and narrowed firing temperature range.

Active Publication Date: 2013-02-13

FOSHAN SHI WAN YING BRAND CERAMICS CO LTD +2

View PDF7 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0013] (1) In order to reduce the firing temperature, the amount of clay raw materials added to the ceramic formula is small, so that the strength of the green body is not enough, and it is easy to break when going on the drying line and decoration line;

[0014] (2) In order to reduce the firing temperature and shorten the firing cycle, a large amount of flux raw materials are introduced into the formula, so that the product is prone to wave deformation, size and other defects during firing, which may cause kiln jam accidents in severe cases;

[0015] (3) Introduce a large amount of flux raw materials, so that the strength of the low-viscosity glass phase in the product is low, and it is easy to crack due to the internal stress during firing and cooling;

[0016] (4) T

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

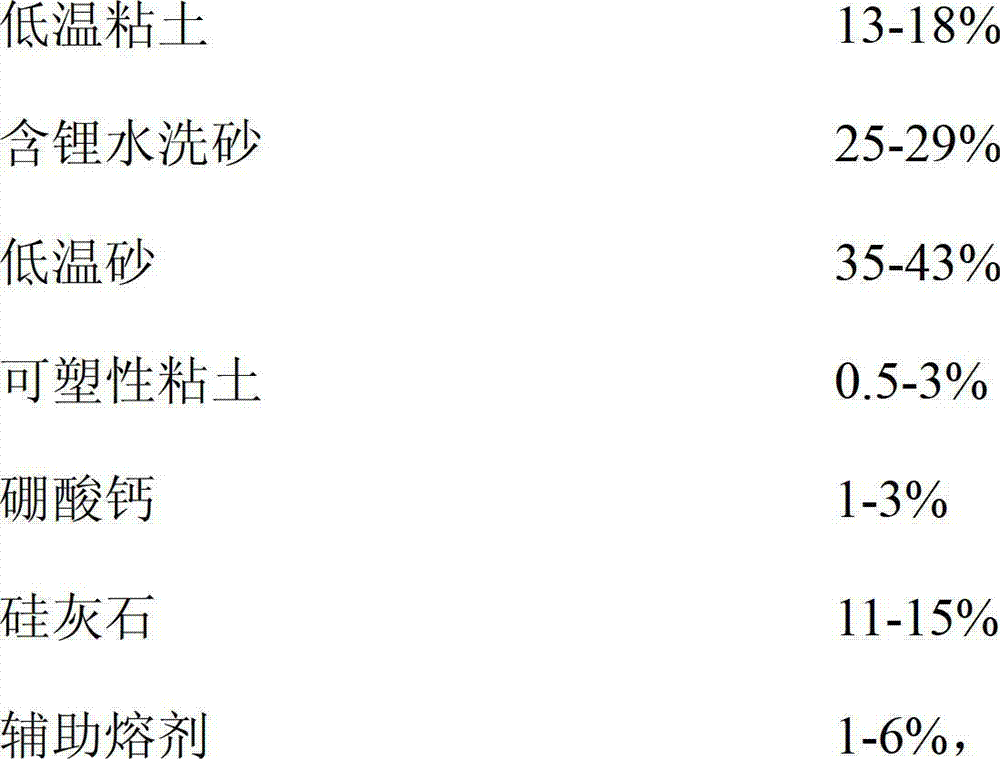

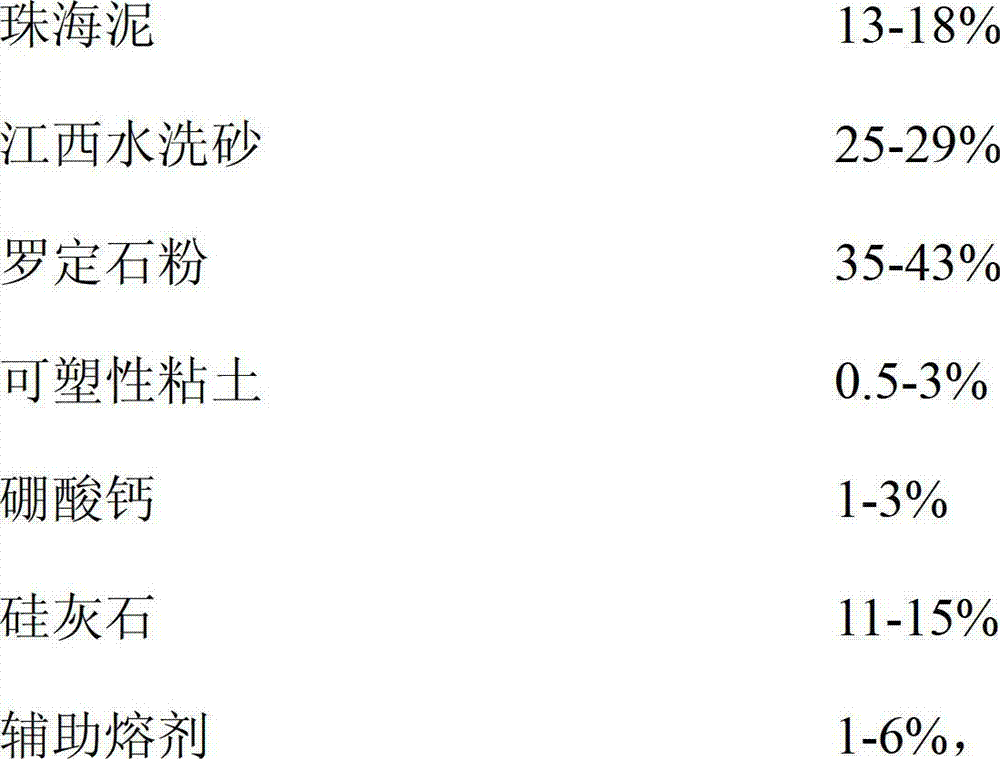

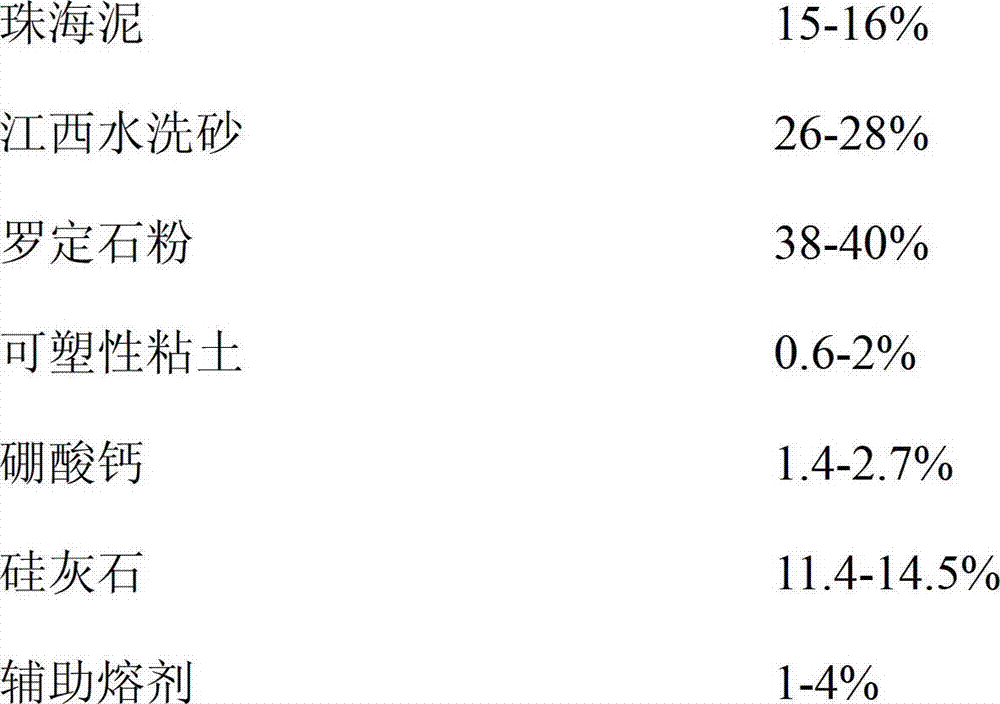

The invention relates to a vitrified ceramic tile blank. The blank comprises 11-15.62wt% of Al203 and further comprises calcium borate. The sintering temperature of the vitrified ceramic tile blank is 1,100+/-20 DEG C, and the sintering time is 45+/-5min. Simultaneously, the problems that due to the fact that massive flux raw materials are introduced in the formula, wave-like deformation and reducers occur easily when products are sintered, and kiln blocking accidents may be caused when the conditions are severe are solved.

Description

technical field [0001] The invention relates to a vitrified ceramic brick blank and a method for preparing the vitrified ceramic brick, in particular to an ultra-low temperature energy-saving vitrified ceramic brick blank and a method for preparing the vitrified ceramic brick, belonging to the field of ceramic processing. Background technique [0002] Vitrified ceramic tiles are one of the main products of architectural ceramics. Its conventional firing temperature is between 1210±20°C, the conventional firing cycle is between 60±5min, and the thickness of conventional products is between 12±2mm. The crystal structure is generally feldspar-mullite structure, and at the same time, a large number of Guangdong black mud and feldspar raw materials, which are relatively scarce in resources, are used in the preparation of vitrified ceramic tiles in the prior art, resulting in a shortage of raw materials for production. Therefore, the existing technology of vitrified ceramic tiles ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C04B35/622C04B35/626

Inventor 林伟陈贤伟曾智林金宏

Owner FOSHAN SHI WAN YING BRAND CERAMICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com