Method and device for bonding stud onto glass

A technology for bonding device and glass, applied in coating and other directions, which can solve the problems of complex overall mold design, high development cost, and difficulty in cleaning the injection molding flash, so as to achieve industrial automatic mass production, beautiful appearance, and low cost. The effect of labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

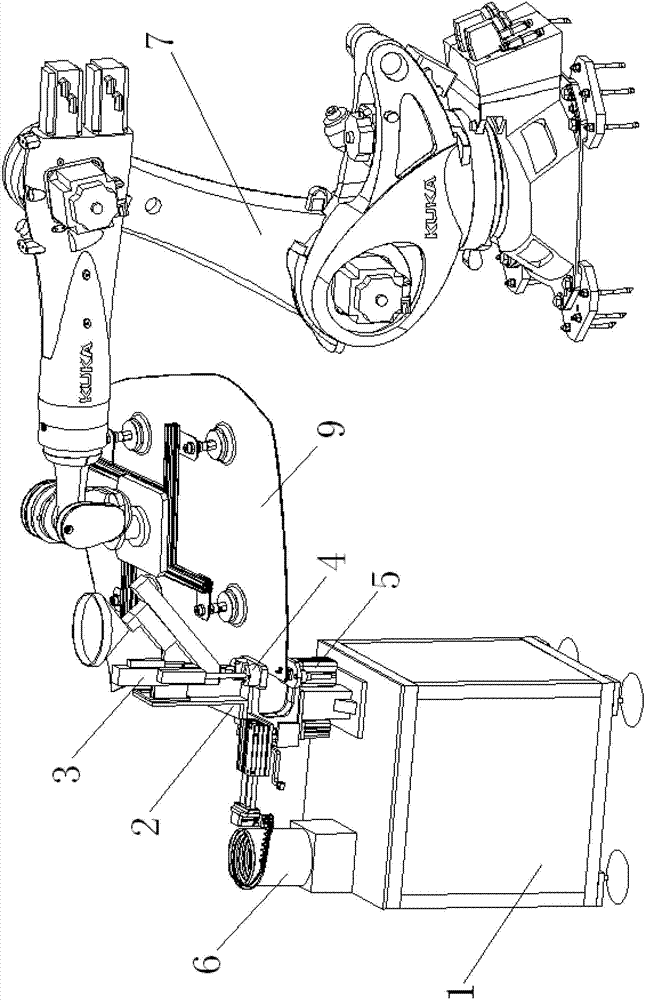

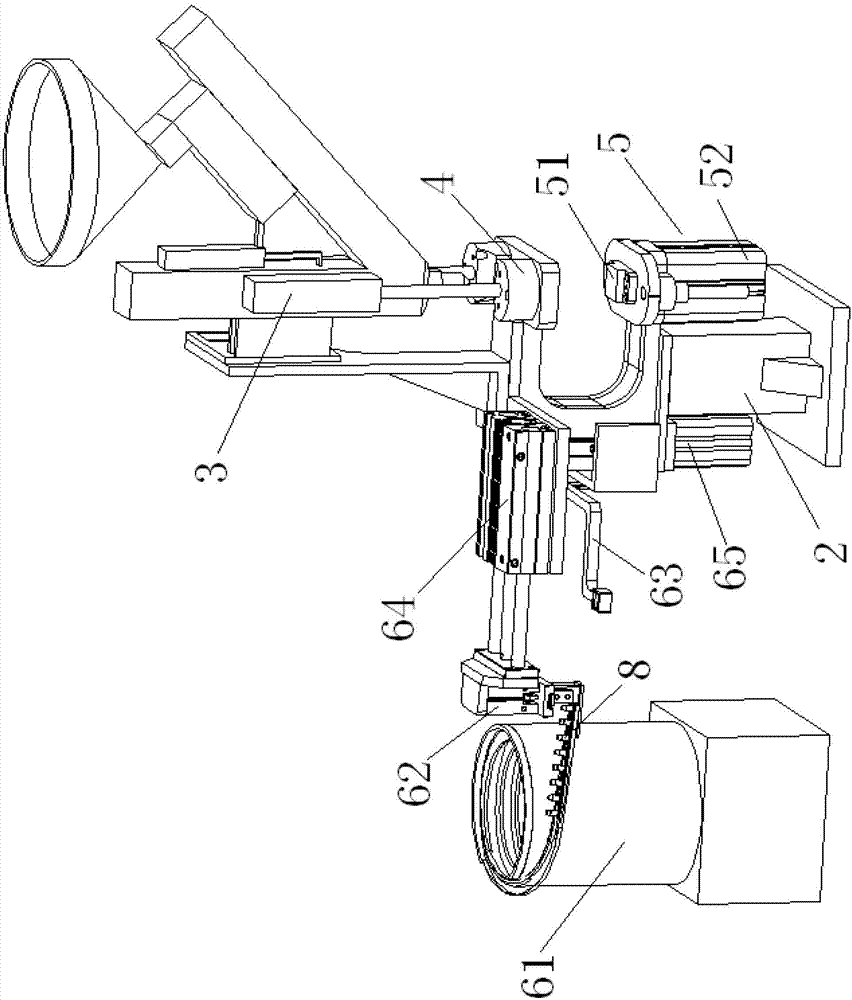

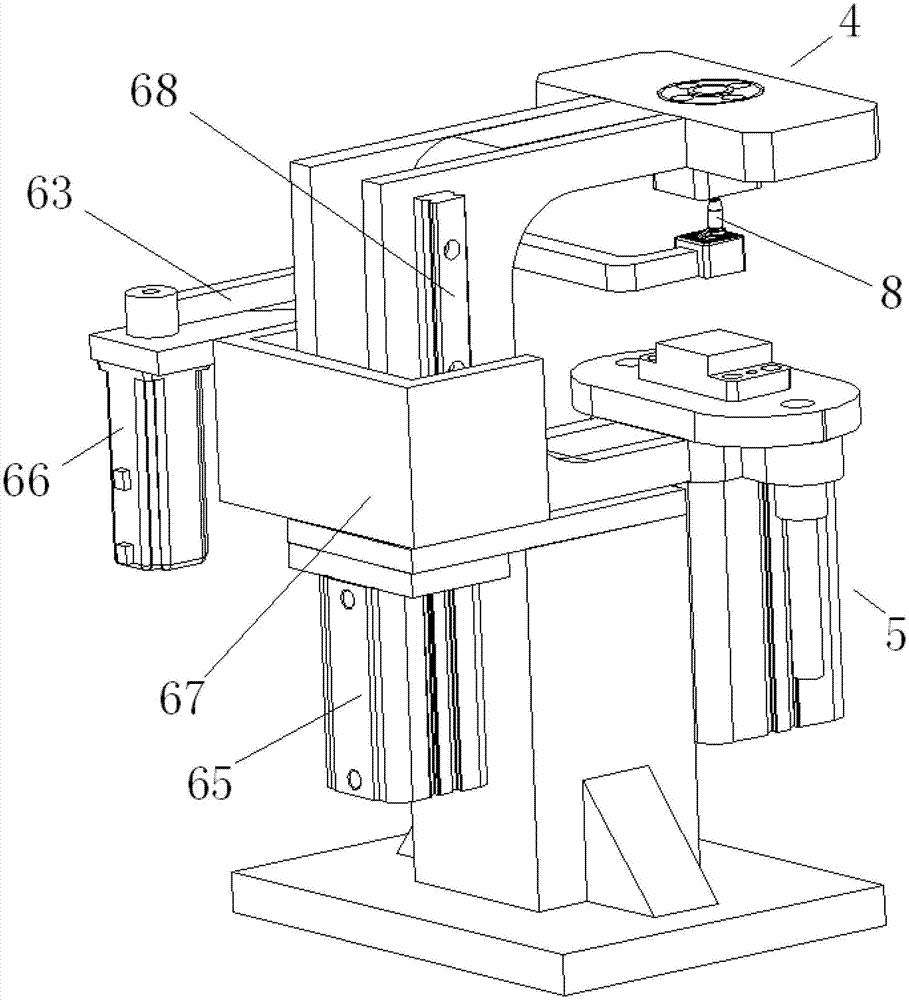

[0044] The content of the present invention will be further described below in conjunction with the accompanying drawings.

[0045] A method for bonding studs to glass according to the present invention is characterized in that the method comprises the following steps:

[0046] Step 01: Coating a primer containing a silane coupling agent on the surfaces to be bonded of the glass 9 and the stud 8 respectively. For automotive glass, only the area where the stud will be bonded should be primed, and for studs, only the underside of the stud should be primed. As the coating method, a brush or roller coating method, a dip coating method, a spray coating method, or the like can be used. In order to make the primer dry quickly, it is best to preheat the substrate with a heater or hot air before applying the primer.

[0047] Step 02: Turn on the injection molding machine 3 and set the injection molding parameters. The injection molding parameters include injection molding temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear load | aaaaa | aaaaa |

| shear load | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com