Energy-saving polyethylene circulating washing device

A cleaning device and polyethylene technology, applied in cleaning methods and appliances, cleaning methods using liquids, water/sludge/sewage treatment, etc., can solve the problems of wasting water resources and polluting the surrounding environment, and avoid re-wasting, Low cost and convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

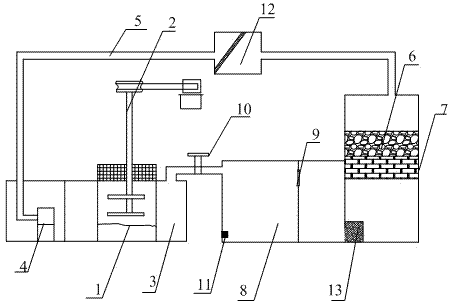

[0022] Such as figure 1 As shown, the polyethylene energy-saving cycle cleaning device includes a net plastic washing tank 1, and a rotary friction cleaner 2 arranged on the net plastic washing tank 1, and the left and right sides of the net plastic washing tank 1 are respectively arranged There is an exchanger main tank 3 and a waste water output device connected thereto. The waste water output device is mainly composed of a waste water output pump 4. The waste water output pump 4 communicates with a waste water regeneration mechanism 7 having a composite filter layer 6 through a waste water output pipe 5. The bottom of the waste water regeneration mechanism 7 is provided with a flow channel, and the side of the waste water regeneration mechanism 7 is provided with a regenerated water secondary storage tank 8 communicated with it through the flow channel. The regenerated water secondary storage tank 8 is divided into a main storage room, and The main storage room communicates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com