Preparation process and application of rosin-based quaternary ammonium salt positive ion surface active agent modified zeolite

A rosin-based quaternary ammonium salt, surfactant technology, applied in chemical instruments and methods, adsorbed water/sewage treatment, other chemical processes, etc., can solve problems such as no reports, and achieve reduced residues, strong adsorption capacity, and a wide range of sources. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

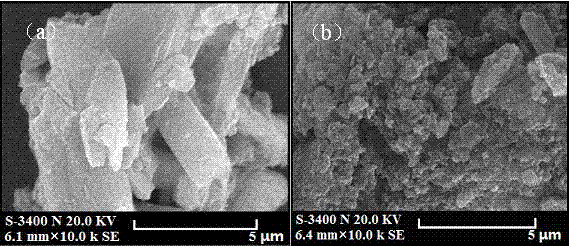

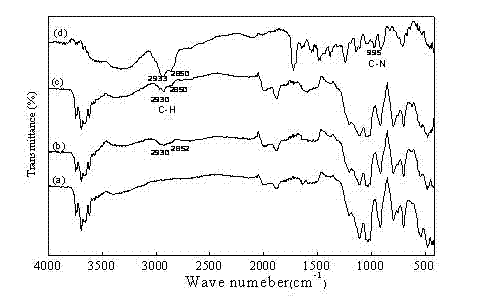

Image

Examples

Embodiment 1

[0043] One. The preparation method of rosin-based quaternary ammonium salt cationic surfactant modified zeolite comprises the steps:

[0044] (1) Raw material pretreatment and reagent configuration

[0045] Take natural zeolite with a certain particle size, wash it several times with distilled water, stir it fully, soak it for 24 hours to reduce its alkalinity, then place it in an oven at 120°C to dry, cool, crush, grind, and pass through a 100-mesh sieve for later use.

[0046] Weigh rosin-based quaternary ammonium salt cationic surfactant (N, N, N-trimethyl-N-rosin-based ammonium chloride), and prepare 50mmoL / L rosin-based quaternary ammonium salt cationic surfactant modification solution with distilled water ,spare.

[0047] (2) Zeolite modification

[0048] Weigh 9 g of zeolite with a particle size of 100 mesh after step (1) and place it in a conical flask, pipette 27 mL of rosin-based quaternary ammonium salt cationic surfactant modification solution with a concentratio...

Embodiment 2

[0053] One. The preparation method of rosin-based quaternary ammonium salt cationic surfactant modified zeolite comprises the steps:

[0054] (1) Raw material pretreatment and reagent configuration

[0055] Take natural zeolite with a certain particle size, wash it several times with distilled water, stir it fully, and soak it for 48 hours to reduce its alkalinity, then put it in an oven at 100°C to dry, cool, crush, grind, and pass through a 200-mesh sieve for later use.

[0056] Weigh a rosin-based quaternary ammonium salt cationic surfactant (N, N-dimethyl-N-benyl-N-dehydroabietyl ammonium chloride), and prepare a 25mmoL / L rosin-based quaternary ammonium salt cationic surface with distilled water Activator modified liquid, spare.

[0057] (2) Zeolite modification

[0058] Weigh 9 g of zeolite with a particle size of 200 mesh after step (1) and place it in a conical flask, pipette 54 mL of rosin-based quaternary ammonium salt cationic surfactant modification solution with ...

Embodiment 3

[0063] One. The preparation method of rosin-based quaternary ammonium salt cationic surfactant modified zeolite comprises the steps:

[0064] (1) Raw material pretreatment and reagent configuration

[0065] Take natural zeolite with a certain particle size, wash it several times with distilled water, stir it fully, soak it for 12 hours to reduce its alkalinity, then place it in an oven at 120°C to dry, cool, crush, grind, and pass through a 150-mesh sieve for later use.

[0066] Weigh rosin-based quaternary ammonium salt cationic surfactant (N, N, N-trimethyl-N-rosin-based-ammonium chloride), and prepare 100mmoL / L rosin-based quaternary ammonium salt cationic surfactant modified with distilled water liquid, spare.

[0067] (2) Zeolite modification

[0068] Weigh 9 g of zeolite with a particle size of 150 mesh after step (1) and put it in a conical flask, pipette 18 mL of rosin-based quaternary ammonium salt cationic surfactant modification solution with a concentration of 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com