Finished product cigarette tobacco blending method in grouped processing mode and blending equipment

A shredded tobacco and finished product technology, which is applied in the blending method of shredded shredded tobacco and the field of blending equipment in the group processing mode, can solve the problems of difficult adjustment of the blending ratio range of shredded tobacco, and no emergency pass available, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

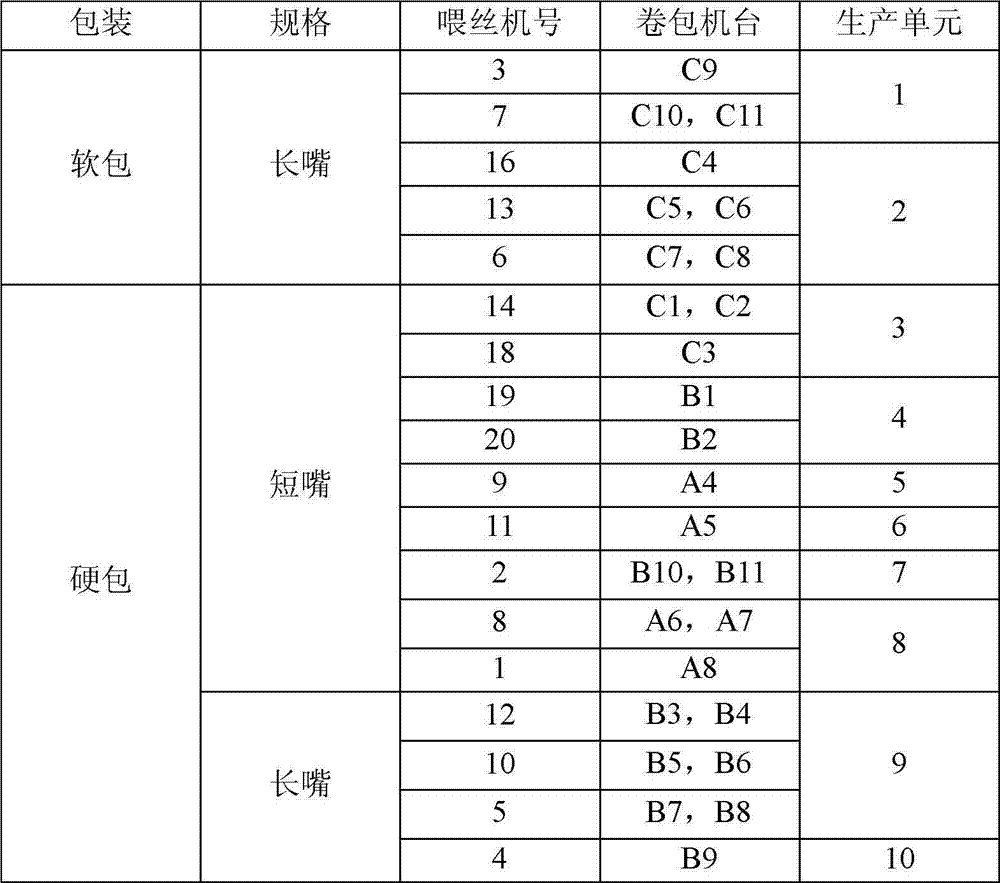

[0051] A method for blending finished shredded tobacco in the group processing mode of the present invention will be described in detail below in conjunction with specific embodiments.

[0052] A method for blending finished cut tobacco in a group processing mode. According to the different dosages of cut tobacco, expanded cut tobacco, cut stem, thin sliced cut tobacco, and recycled cut tobacco, nine passes of different measuring ranges are selected for blending, and each of the nine passes The ranges are as follows:

[0053] The first category of shredded tobacco passes, with a measuring range of 1326-5600 kg / h;

[0054]The second category of shredded tobacco passes, with a measuring range of 663 to 3600 kg / h;

[0055] The third category of shredded tobacco passes, with a measuring range of 663 to 3600 kg / h;

[0056] Passage of expanded shredded tobacco, the measuring range is 339-1337 kg / h;

[0057] The first stalk pass, the measuring range is 151-500 kg / h;

[0058] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com