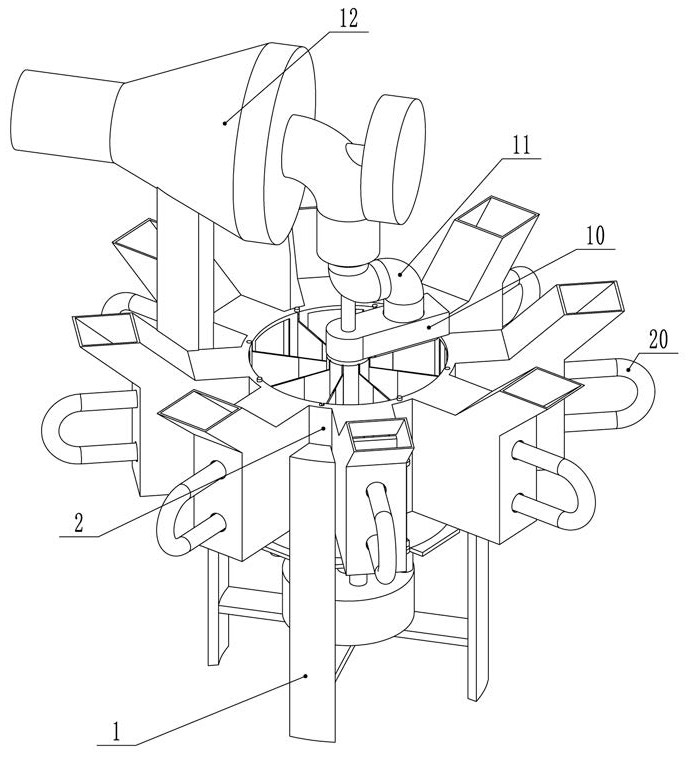

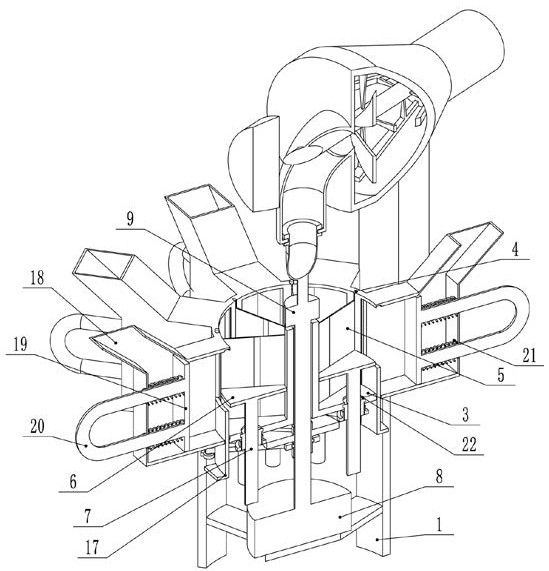

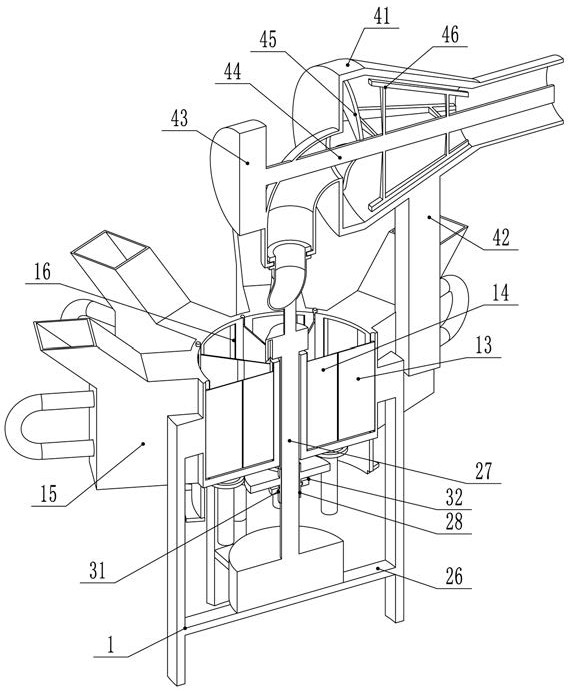

A high-efficiency cotton blender

A cotton blending machine, high-efficiency technology, applied in textiles and papermaking, fiber processing, fiber feeding, etc., can solve the problems of insufficient mixing of various materials, affecting production efficiency, slow mixing speed, etc., and expand the scope of use , shorten the time required for feeding, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1, a high-efficiency cotton blender, when in use, determines the number of storage tanks 3 according to the types of materials to be mixed, and installs the position of the partition 5 according to the use ratio of various materials , slide the slide plate 14 out from the inside of the outer plate 13, thereby making the overall length and sides longer, so that the partition plate 5 is more firmly clamped inside the compartment 4. Assuming that there are 8 storage tanks 3 in total, three storage tanks are required. The three materials are cotton, hemp and fiber, and the three ratios are 2:1:1, so there are four storage tanks 3 for storing cotton, two storage tanks for storing hemp, and two storage tanks for fiber. Two storage tanks 3 for cotton, one storage tank 3 for hemp, one storage tank 3 for fiber, two storage tanks 3 for cotton, one storage tank 3 for hemp, and one storage tank 3 for fiber can be installed in order. It can also be set in the order of four s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com