Noise-optimized toothing system

A noise and tooth technology, applied to components with teeth, engine starting, belt/chain/gear, etc., can solve the problems of increased wear of the motor commutation system, deterioration of vibration characteristics and efficiency, and shortened service life of the motor. , to achieve the effect of improving noise level and vibration characteristics, increasing service life and reducing noise level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

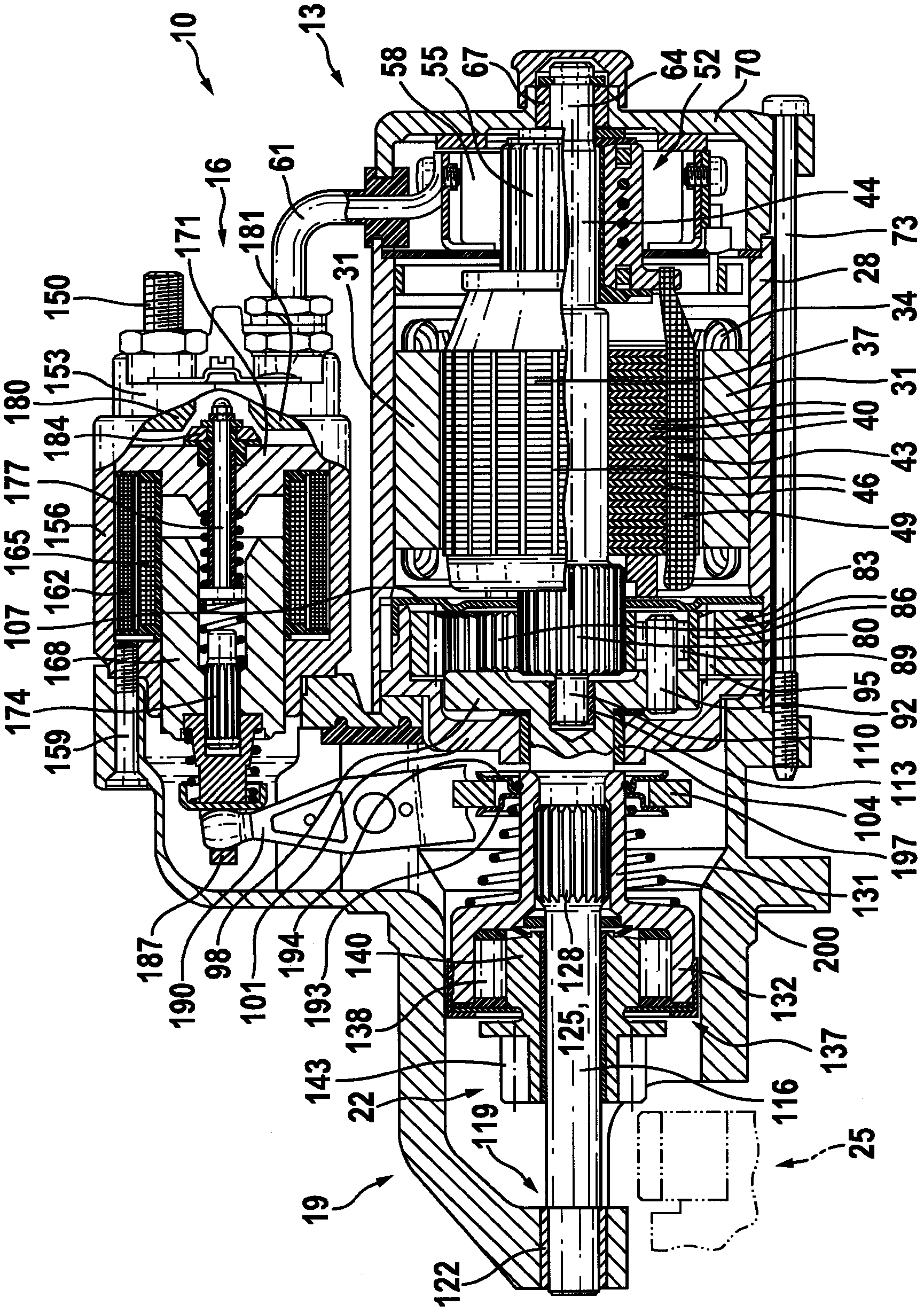

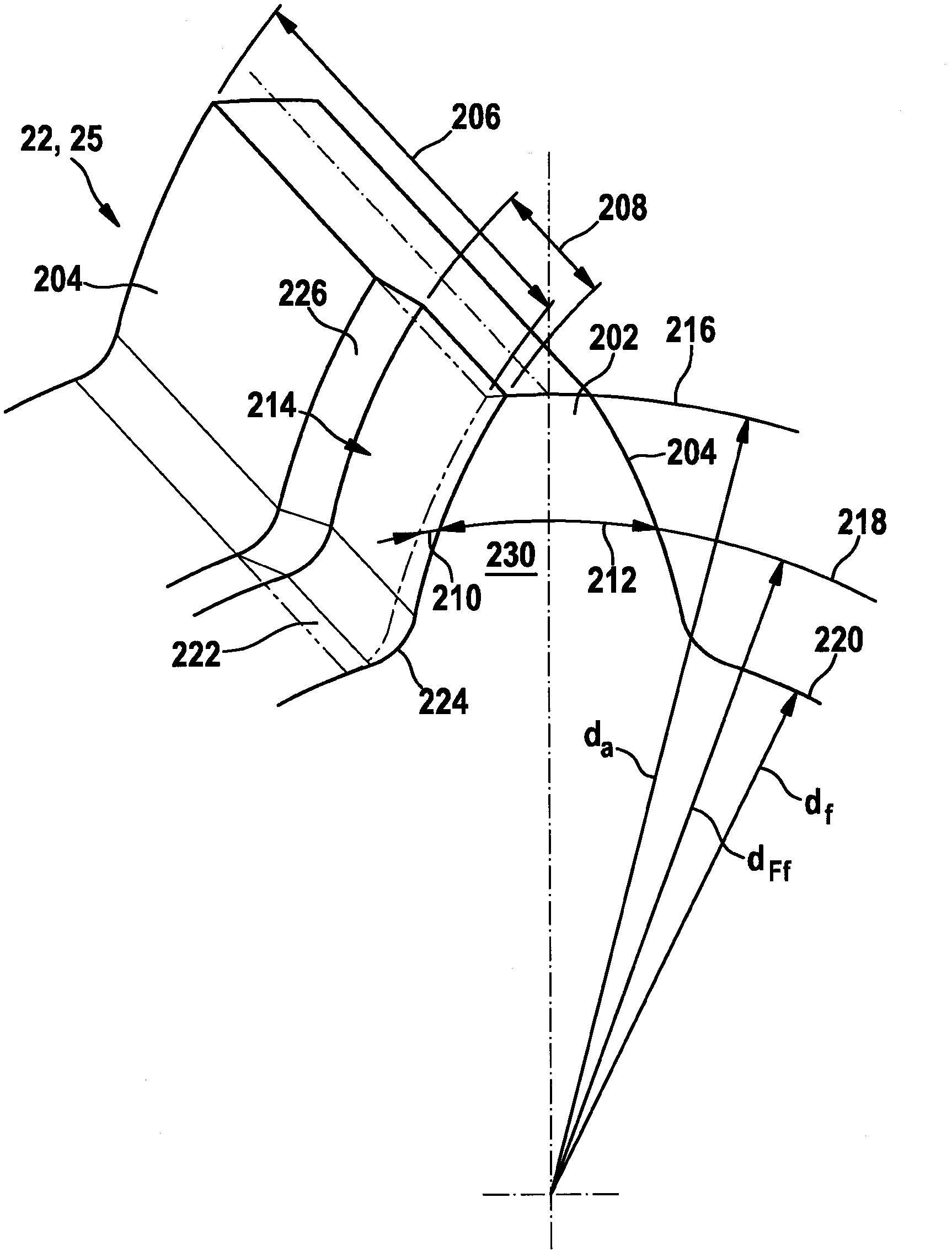

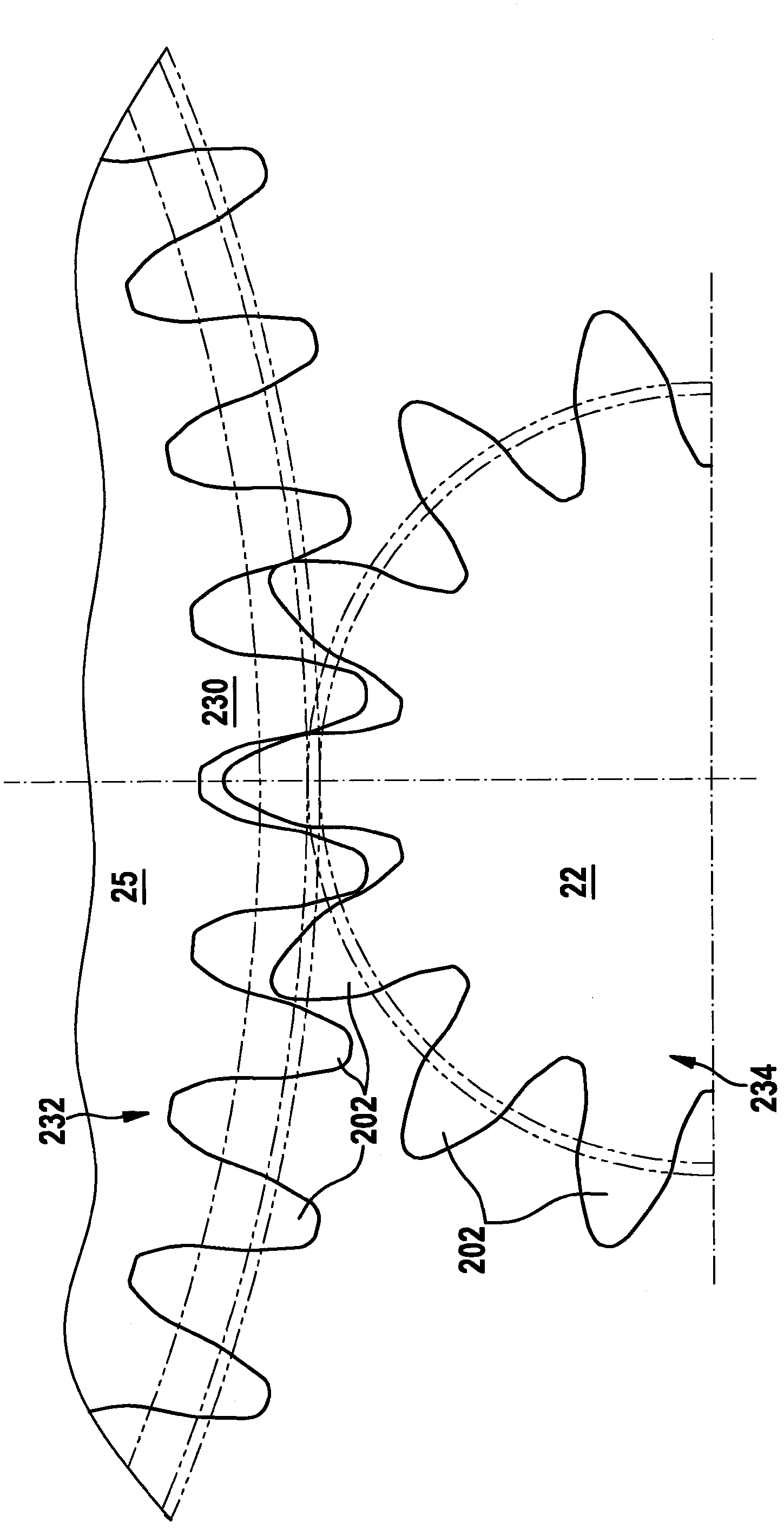

[0030] figure 1 The starter device 10 is shown in longitudinal section. The starter device 10 has, for example, a starter motor 13 and a pre-engagement actuator 16 (eg relay, starter relay). The starter motor 13 and the electric pre-engagement actuator 16 are fastened to a common drive end bearing shield 19 . The starter motor 13 is functionally used when the starter pinion 22 is engaged to figure 1 The ring gear 25 of the internal combustion engine, not shown, drives the starter pinion 22 in the center. The starter motor 13 has a pole tube 28 as a housing, which supports on its inner circumference a plurality of pole shoes 31 , which are each wound by a field winding 34 . For starters of smaller power classes, permanent magnets are also conceivable here instead of pole pieces 31 and field winding 34 . The pole piece 31 in turn encloses an armature 37 which has an armature lamination stack 43 consisting of laminations 40 and an armature winding 49 arranged in a plurality o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com