Segmentation control method for low-voltage ride-through of doubly-fed motor during symmetric drop of network voltage

A low-voltage ride-through and grid voltage technology, applied in control systems, control generators, electrical components, etc., can solve problems such as unfavorable grid restoration, achieve optimal design, shorten protection time, and enhance low-voltage ride-through capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

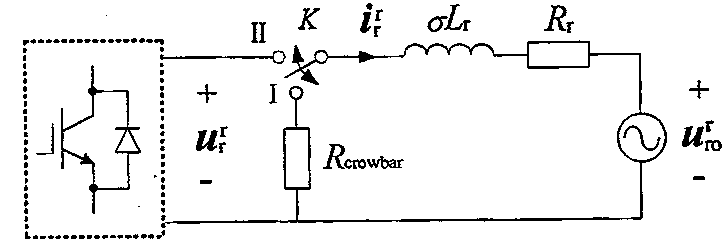

[0024] This embodiment provides a segmented control method for low-voltage ride-through of double-fed motors when the grid voltage drops symmetrically. The specific application environment is based on the simulation software Matlab / Simulink, and the above-mentioned segmented control method for low-voltage ride-through of double-fed motors is verified. It improves the low voltage ride-through capability of the system and contributes to the rapid recovery of the power grid. The parameters of the DFIG used in the simulation are: rated power 4kW, stator voltage 310V, rated frequency 50Hz, stator resistance 1.405Ω, rotor resistance 1.395Ω, crowbar protection resistance 5Ω, stator leakage inductance 0.005839H, rotor leakage inductance 0.005839H, Mutual inductance 0.1722H, number of pole pairs 2.

[0025] The specific implementation steps are as follows:

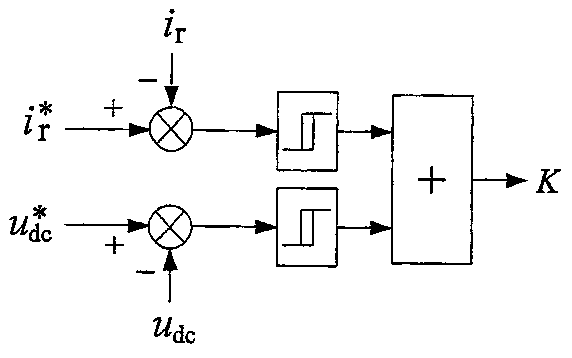

[0026] ① Separately detect the rotor current and the DC bus voltage;

[0027] In this embodiment, because it is performed in Ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com