Indoor ground screen reconstruction method for S band continuous wave high-power microwave system

A technology of microwave system and ground network, which is applied in the direction of connection, connection contact material, electrical components, etc., can solve the problem of device damage and other problems, and achieve the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

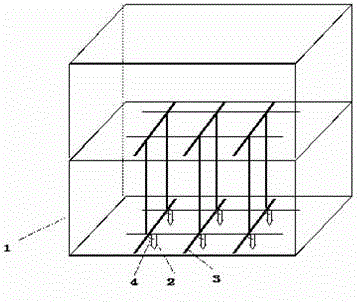

[0023] (1) The 2.45GHz / 4MW continuous wave microwave system is built indoors. The main part consists of upper and lower floors, of which the lower floor is placed on the bottom floor of building 1 (there is no basement in the building), and the location close to the klystron is selected for grounding pile;

[0024] (2) Based on the indoor ground level, drill holes with a depth of 2.5m and a diameter of 2cm at six ground pile positions;

[0025] (3) Bury ground piles 2, wherein the ground piles 2 are copper-clad steel with a diameter of 2cm and a length of 2m;

[0026] (4) Make a C-type connector 4, wherein the material of the C-type connector 4 is copper;

[0027] (5) Weld the ground pile 2 and the C-shaped connector 4, and bury the ground pile 2 and part of the connector 4, wherein the ground pile 2 corresponds to the connector 4 one by one;

[0028] (6) Lay a three-dimensional ground net 3 on the upper and lower floors where the microwave system is located, and the materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com