Earth leakage protection socket with jack baffle device

A baffle device and leakage protection technology, which is applied to the parts, coupling devices, circuits, etc. of the connecting device, can solve the problems of limited space for assembling small baffles, limited height of guide rails and chutes, and high processing and assembly requirements. Reasonable structure and matching relationship, stable and smooth movement, and the effect of increasing assembly space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

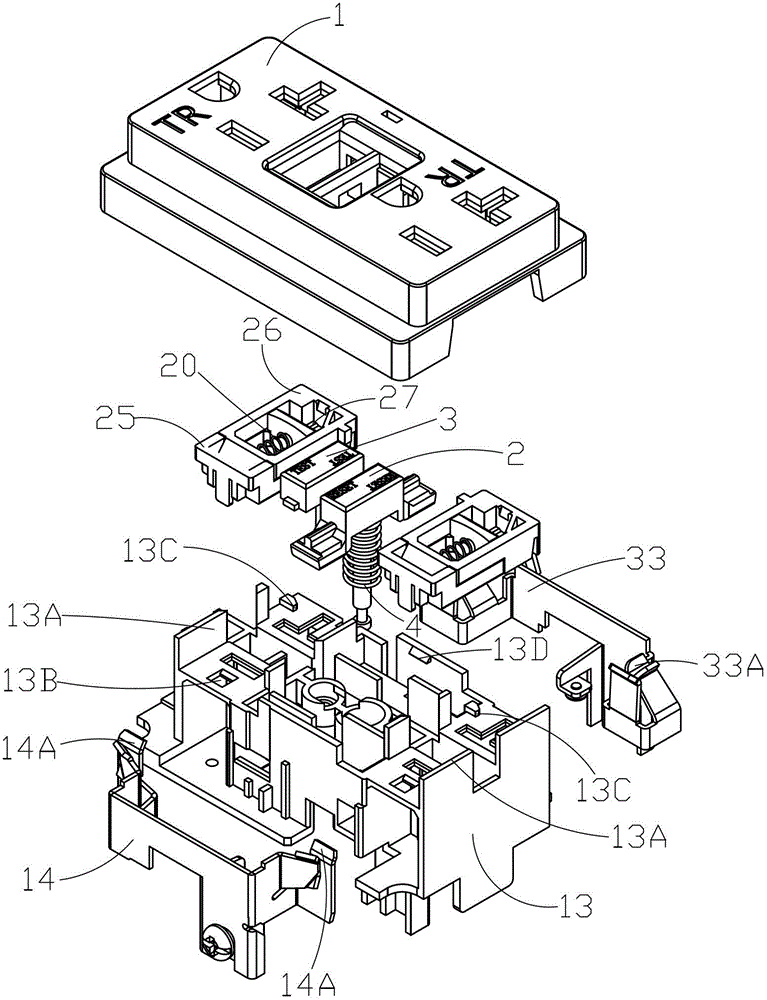

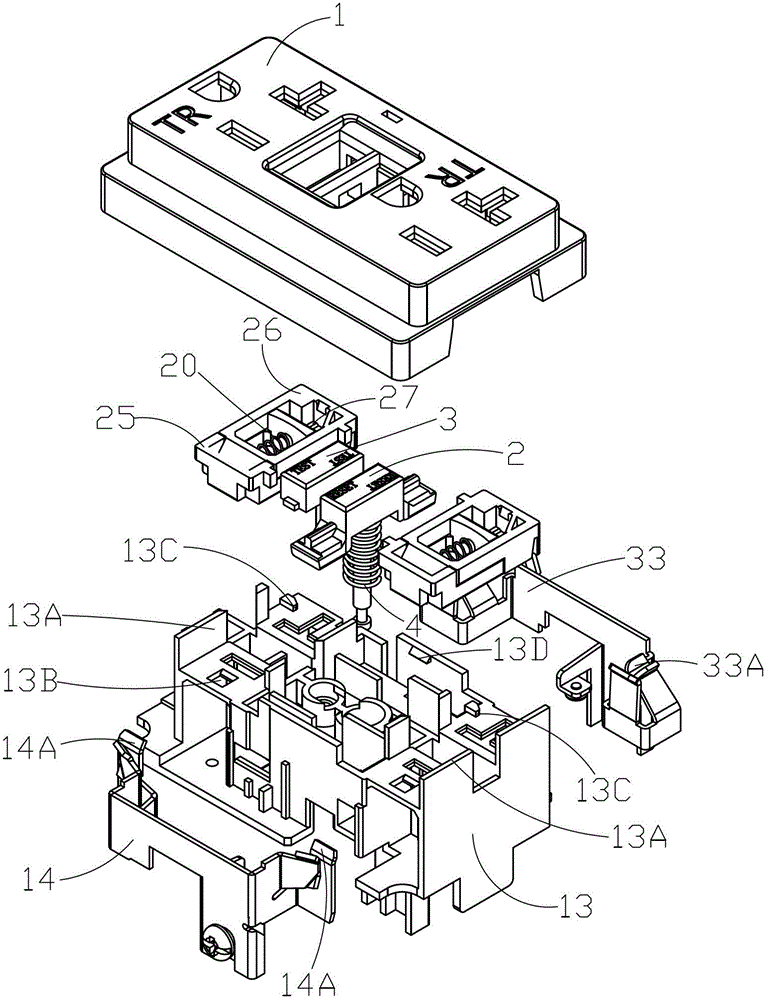

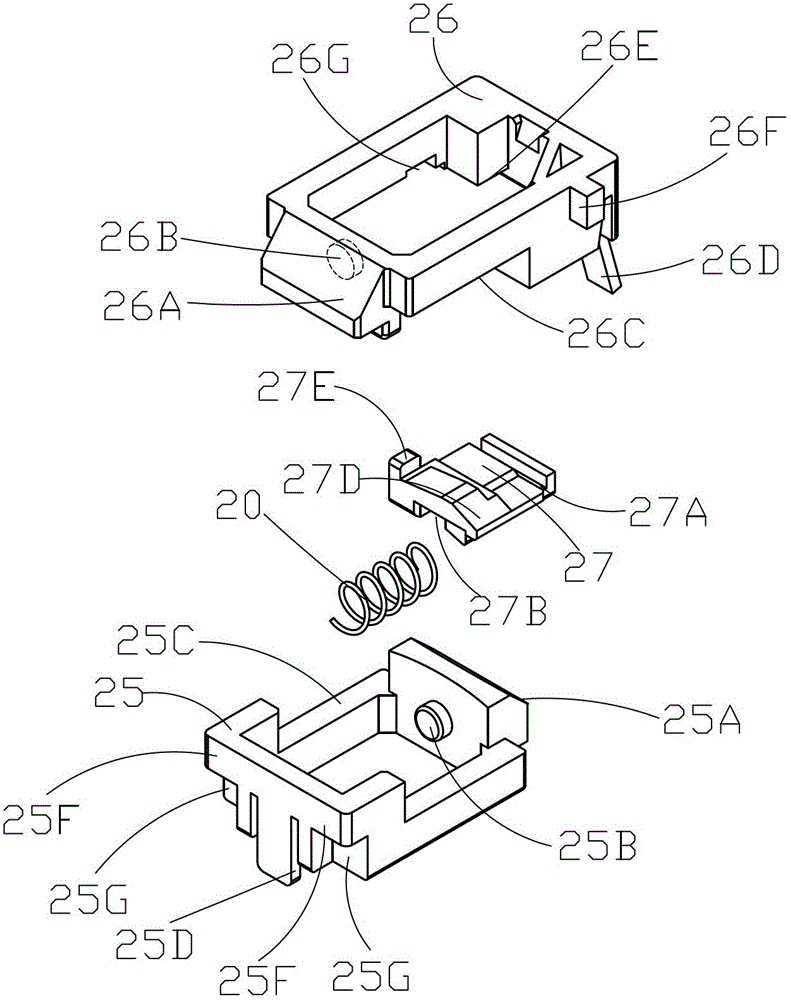

[0032] refer to figure 1 , image 3 , Figure 4 , Figure 7 as well as Figure 9 Figure 12 , a leakage protection socket with a jack baffle device, including a housing with a middle bracket 13 inside (including an upper cover and a base, figure 1 Only the upper cover 1), the conductive sockets 14, 33 located under the middle bracket 13, and the jack baffle device are shown in the figure. The middle bracket 13 is provided with a guide hole 13G corresponding to the position of the conductive socket, and the jack baffle The device includes a slidable cross-fit left baffle 25 and a right baffle 26 and a small baffle 27 below the right baffle; one end of the right baffle 26 is stripped off to form a guide rail 26G for the small baffle to slide and translate (refer to Figure 10 ), the top of the small baffle 27 is provided with a first guide groove 27A that cooperates with the right baffle guide rail 26G; the top of the small baffle 27 is also provided with a walking slope 27...

Embodiment 2

[0043] refer to figure 2 , Figure 6 , Figure 8 , the lower side of the outer side wall of the left baffle in embodiment 1 is provided with positioning feet 25D, the setting of the positioning feet is to make the operation of the left baffle more stable and prevent shaking in the direction perpendicular to the opening direction, but the setting of the positioning feet is also increased. To reduce the processing cost, due to the setting of the guide side wall 13A of the middle support, and the right baffle has been limited by the elastic feet, in order to simplify the processing and assembly process, in the present embodiment, the left baffle 25 is not provided with positioning feet; The locking mechanism cooperates, and the positioning groove 25G or the positioning convex nail (25H or 25J) can be separately set on the left baffle plate 25, or both can be set, so as to adapt to various leakage protection sockets and save mold cost.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com