Preparation method of electrode material for super-capacitor

A technology for supercapacitors and electrode materials, applied in the manufacture of hybrid/electric double layer capacitors, etc., can solve the problems of small specific capacitance and low specific surface area of porous carbon materials, and achieve increased capacitance, good supercapacitive properties, and good deposition effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0019] Embodiment 1: In this embodiment, a method for preparing an electrode material for a supercapacitor is specifically prepared according to the following steps:

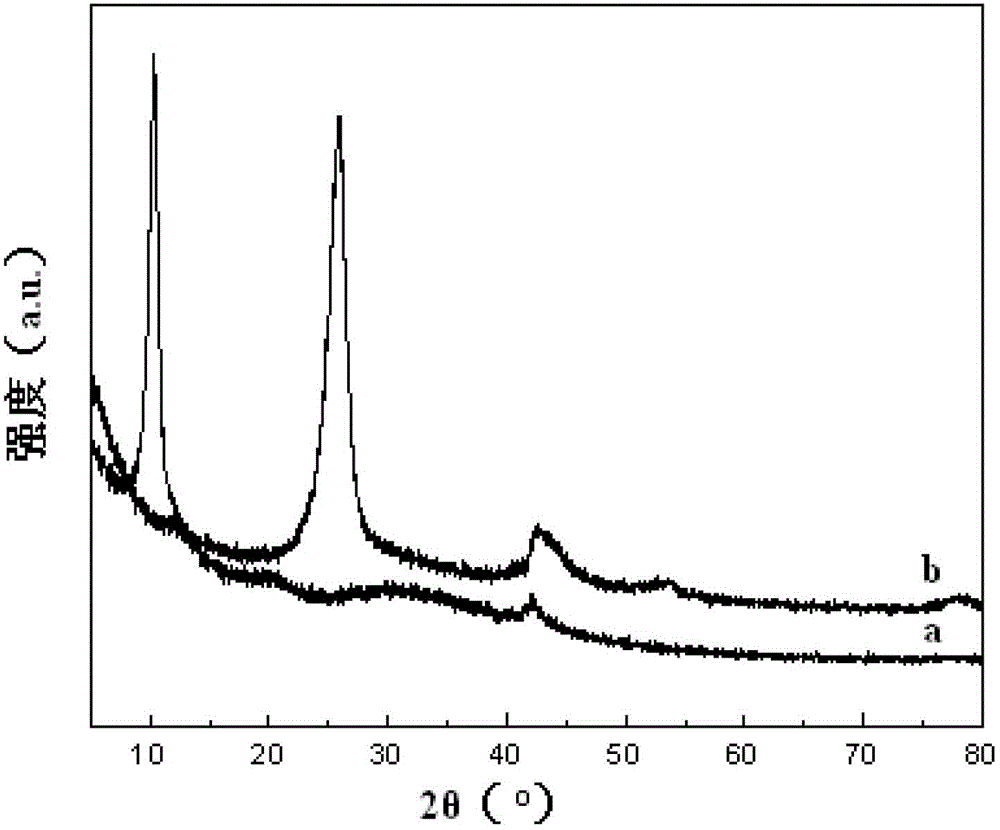

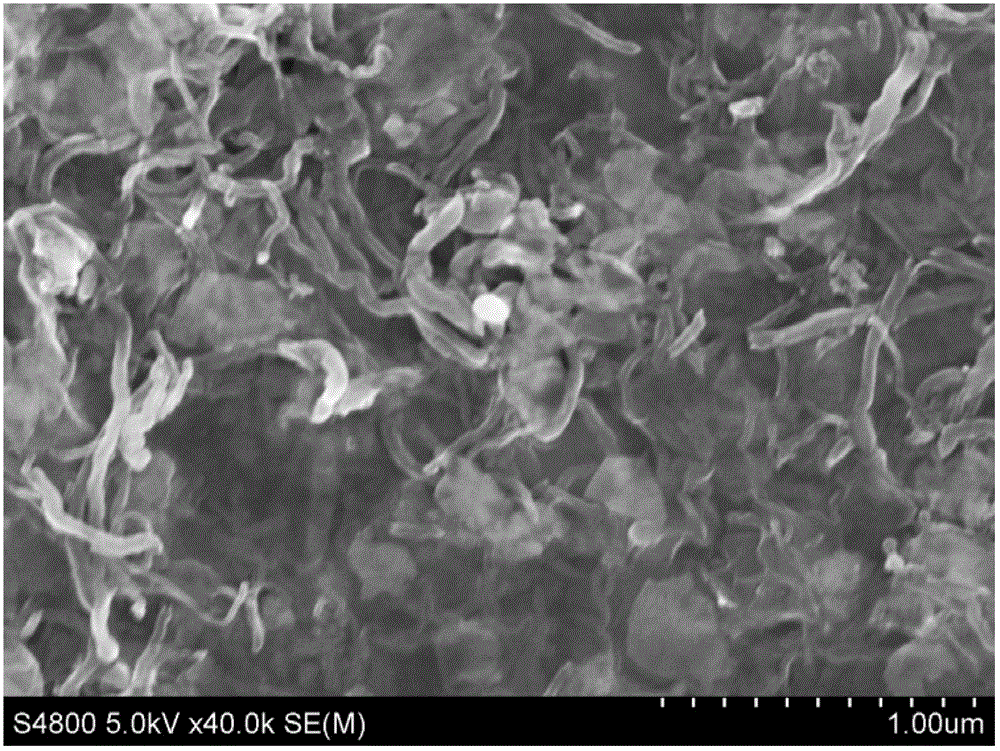

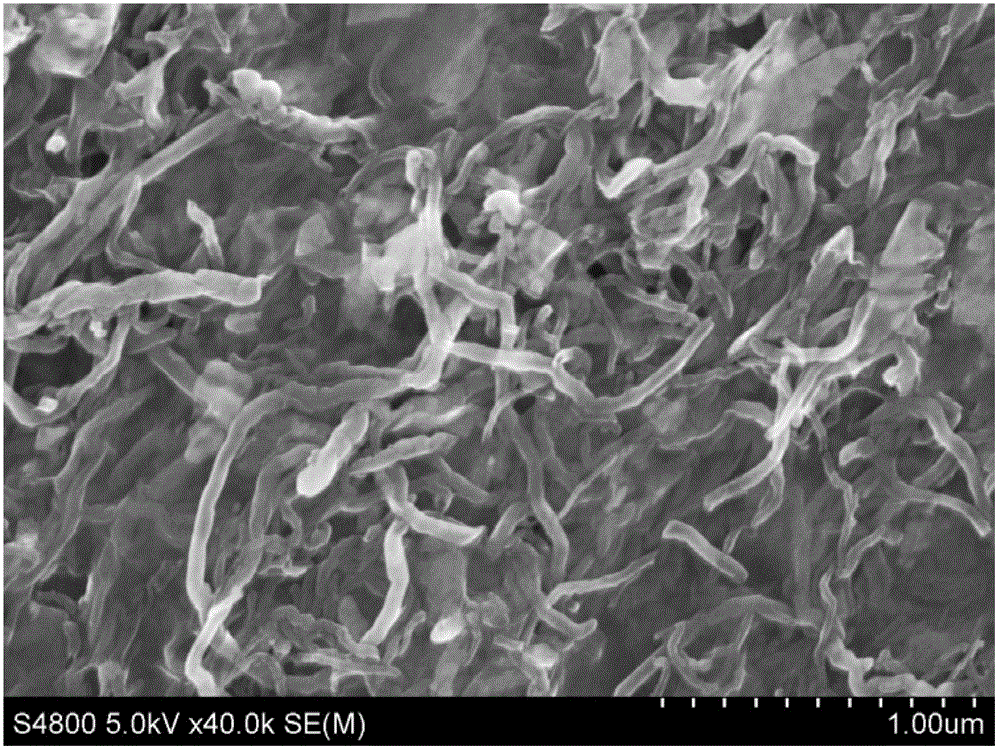

[0020] 1. Preparation of graphene oxide aqueous dispersion by modified Hummer`s method: Weigh 1.0g~1.4g of phosphorus flake graphite, 58mL~62mL of 98% H 2 SO 4 solution, 6.5mL~6.9mL phosphoric acid solution with a mass concentration of 85%~98%, 6g~10g KMnO 4 , 280mL~320mL deionized water and 28mL~32mL 30% hydrogen peroxide solution; add H 2 SO 4 solution, phosphoric acid solution and KMnO 4 , kept for 2h~2.5h, then moved into a water bath with a temperature of 32°C~37°C, kept for 18h~22h, then added deionized water, and after standing for 10min~15min, added hydrogen peroxide solution. The whole step was carried out under stirring conditions. Obtain a solid-liquid mixture; then let the solid-liquid mixture stand until solid-liquid separation, take the solid part, wash it with deionized water and hydrochloric ...

specific Embodiment approach 2

[0026] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the mass concentration of the hydrochloric acid solution in step 1 is 3%. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0027] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the mass ratio of graphene oxide to carbon nanotubes in step 2 is 5:5. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com