High-throughput method for extracting carotene in biological sample

A carotene and biological sample technology, applied in the field of carotenoid production and research, can solve the problems of high operating cost, high labor intensity, complicated process, etc., and achieve the effect of avoiding a large amount of reagent expenses, reducing energy consumption, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

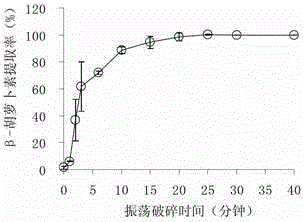

[0052] Three groups of parallel samples were set up for each group of conditions, the diameter of the crushing and oscillating crushing beads was 6mm, the number of crushing and oscillating crushing beads used was 15, the crushing speed was 400rpm, the inclination angle of the crushing tube was 0°, and the weight of the analyzed sample was about 0.2g. break time press figure 1 The range of conditions described in:

[0053] According to the analysis of implementation results, it can be seen that when the crushing time reached 30min, the crushing extraction rate of three groups of parallel samples all reached 100%, and as the crushing time prolongs, the extraction rate of β-carotene in B. trispora reached 100%. level remains unchanged. It can be seen that, by selecting a suitable crushing time, the present invention can be effectively implemented in the extraction of B. trispora β-carotene; wherein, considering the shortening of the extraction time and the stability of the extr...

Embodiment 2

[0055] In order to ensure that the present invention can be effectively implemented in the extraction of β-carotene in B. trispora. In this embodiment, the sizes and specifications of the broken beads are examined. Under the implementation conditions that the number of crushing and oscillating crushing beads used is 15, the crushing speed is 400rpm, the crushing time is 30min, the inclination angle of the crushing tube is 0°, and the weighing of the analysis sample is about 0.2g, this embodiment examines 4mm, 5mm and Effects of 6mm broken beads of three different sizes on the implementation of the invention.

[0056] According to the results of the invention, it can be seen that within the scope of the size of the broken beads, the β-carotene in the B. trispora can be fully extracted. Among the three groups of experiments, the 6mm steel ball has the best crushing effect and the highest working efficiency.

Embodiment 3

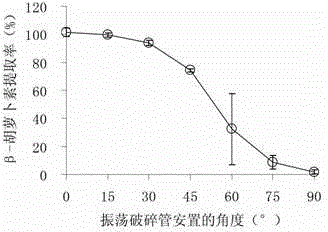

[0058] By changing the angle of the broken tube fixing frame, the implementation of the present invention on the extraction of β-carotene in the cells of B. trispora was investigated. Lock the oscillating crushing tubes containing 15 oscillating crushing beads with a diameter of 6 mm, about 0.2 g of B. trispora cells, and 5 ml of extraction solvent in fixed frames with different placement angles, and place them on a shaker with a crushing speed of 400 rpm Breaking time 30min, investigate the enforcement of the present invention with this, the result is as follows image 3 shown.

[0059] According to the analysis of the results of this embodiment, it can be seen that when the installation angle of the oscillating broken tube is 90° (perpendicular to the gyratory oscillation plane), the cell crushing effect (or β-carotene extraction efficiency) is the worst; as the inclination angle increases continuously, Under the condition that other conditions remain unchanged, the crushin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com