Novel comprehensive hole-series position degree gauge

A technology of comprehensive inspection tools and position degree, which is applied in the direction of measuring devices, mechanical devices, mechanical measuring devices, etc., can solve the problems of increasing production costs, high testing and maintenance costs, reduce maintenance costs, facilitate testing management, and reduce production costs. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing, the present invention is described in further detail:

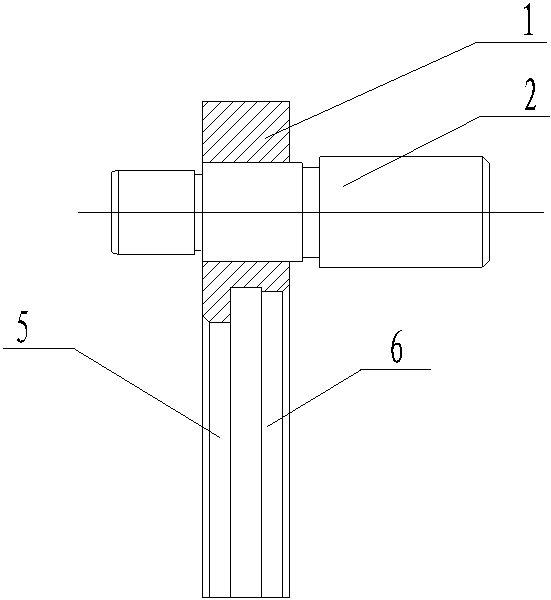

[0015] Such as figure 1 As shown, a new type of hole system position degree comprehensive inspection tool, which is composed of the inspection tool body 1 and the positioning pin 2, the upper end of the inspection tool body 1 is inserted into the positioning pin 2, and the inspection tool body 1 is set into steps, see figure 1 5, 6 of them.

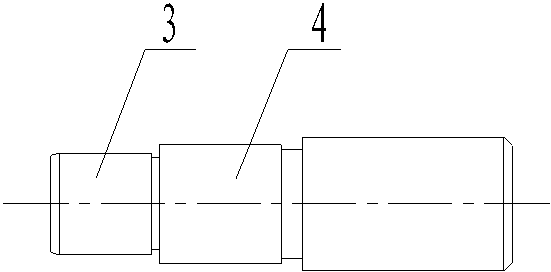

[0016] Such as figure 2 As shown, the stepped positioning pin 2 in the present invention is composed of a measuring part 3 and a positioning part 4. The measuring part 3 is connected to the measured measuring hole, and the positioning part 4 is connected to the inspection tool body 1.

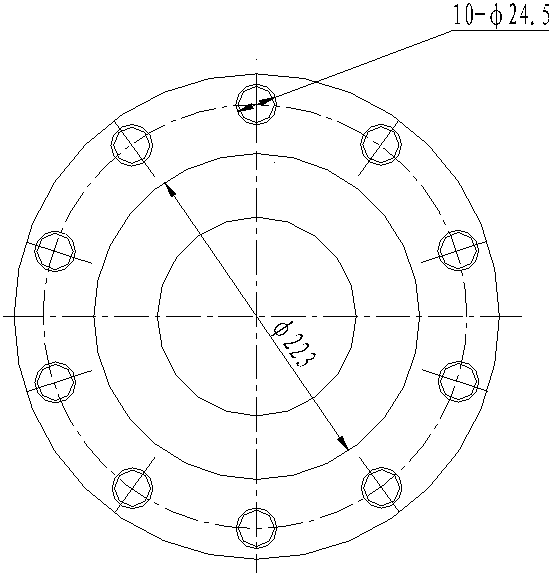

[0017] image 3 It is the tested part whose model is designated as 01, the diameter of the bolt hole is φ24.5, and the diameter of the positioning hole is φ223. Figure 4 The measured part is designated as 02, the diameter of the bolt hole i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com