Pulsation porous medium combustion power generation system

A technology of porous media and combustion power generation, which is applied in steam generation, machines/engines, steam boilers, etc. It can solve the problems of lower energy utilization efficiency, insufficient use of flue gas, and heat loss of flue gas, so as to overcome the fluctuation of thermal energy , make full use of waste heat, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

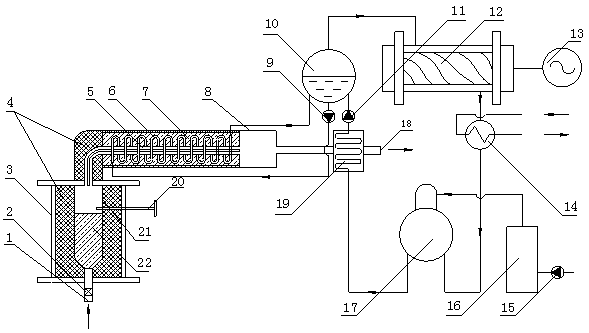

[0015] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0016] The pulsating porous medium combustion power generation system of the present invention is mainly composed of a burner, a heat exchange device, a preheating device, a circulating water treatment system and a screw expander 12 connected to a generator 13; the burner is a pulsating porous medium The burner, the pulsating porous medium burner includes a burner housing 3, an insulation layer 4 is attached to the inner wall of the burner housing 3, and an inner cylinder 21 equipped with a porous medium combustion chamber 22 is arranged inside the insulation layer 4, and the upper part of the inner cylinder 21 An igniter 20 penetrating into the burner housing 3 is provided, and the porous medium combustion chamber 22 is a SiC foam ceramic porous medium combustion chamber or an Al 2 o 3 Foam ceramic porous media combustion chamber. The lower part of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com