Steel tube concrete column high-altitude construction safety protection system

A steel pipe concrete column and high-altitude construction technology, which is applied in the direction of building structure support, building structure support, building structure support scaffolding, etc., can solve the problems of potential safety hazards, scaffold disintegration and collapse, and complicated installation, so as to save materials, assemble and disassemble Simple and fast, easy and fast disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

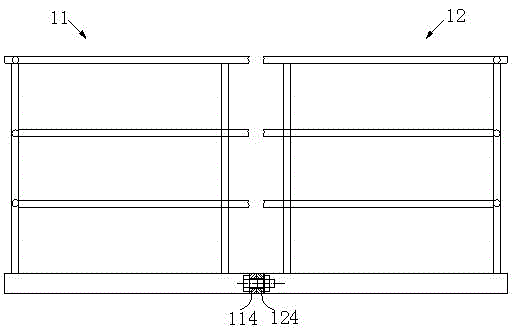

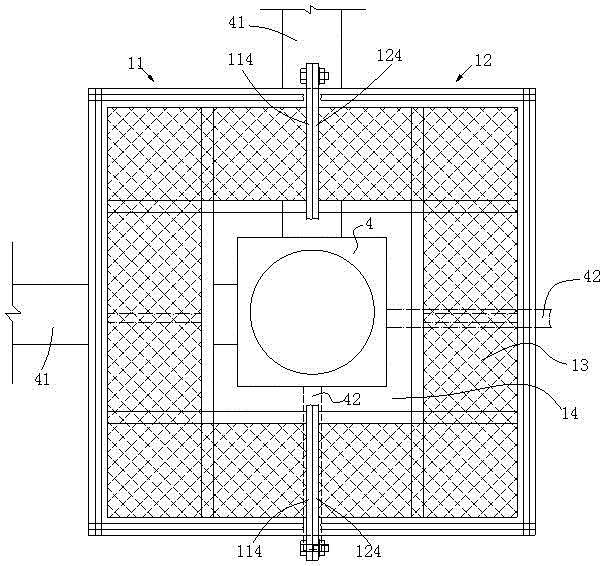

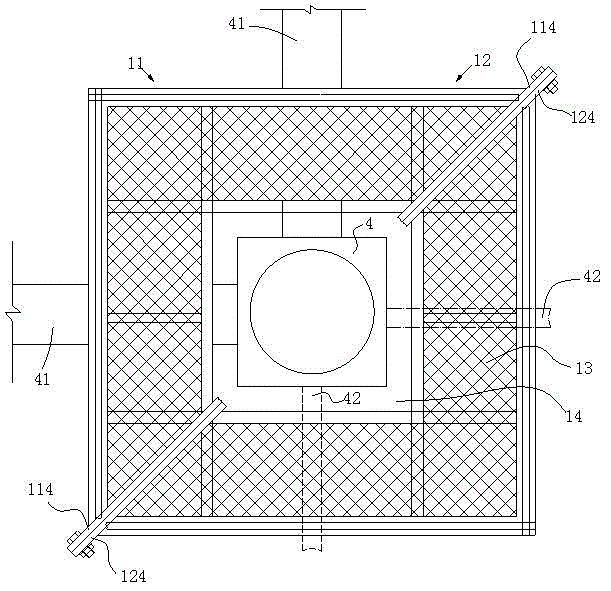

[0023] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0024] The technical scheme of the present invention is especially suitable for the construction of steel tube concrete columns in high-rise buildings. Each steel tube column is generally 2 to 3 stories high. The steel tube column is a hollow steel tube with grouting holes on the top surface. The steel tube concrete column referred to in the present invention refers to It is a combination of steel tube column and concrete after pouring concrete. During construction, after each section of steel pipe column is hoisted in place, the concrete inside the column is poured. After pouring a layer of steel pipe column, a layer of steel pipe column is hoisted and welded on the top of the layer of steel pipe column, and the upper layer of steel pipe The columns are constructed before the lower floor. Therefore, every time the concrete pouring in the steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com