Double-impact integral hydraulic tapping machine

An opening machine and hydraulic technology, applied in blast furnace parts, furnace, blast furnace details, etc., to achieve the effect of shortening the withdrawal time, high impact frequency, and avoiding misoperation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

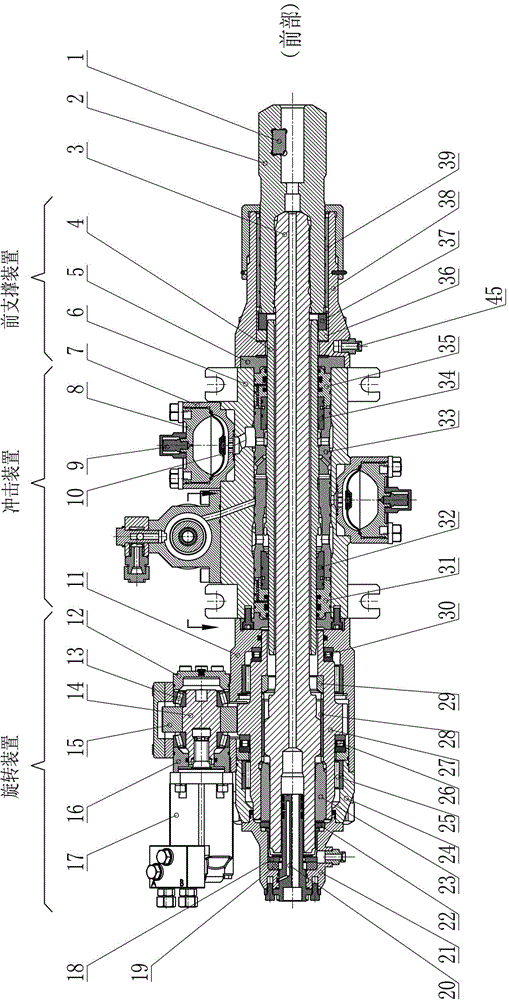

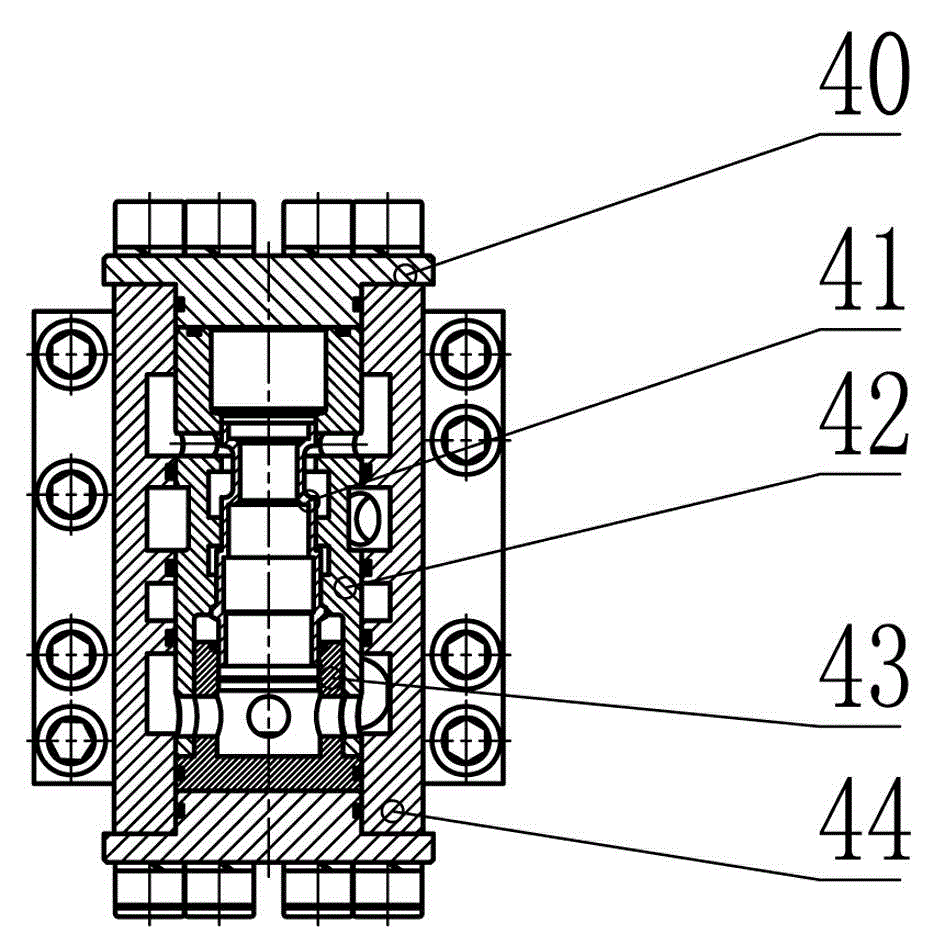

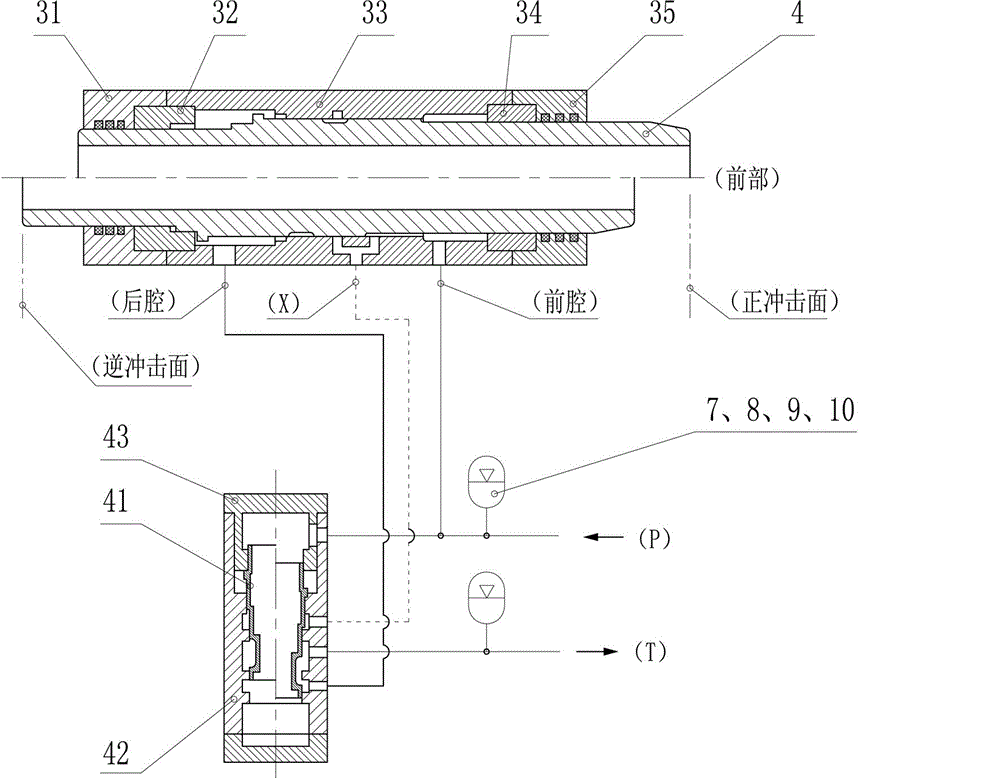

[0029] Such as Figure 1-7 A double-strike integrated hydraulic opening machine is shown, which includes a drilling tool assembly. A front support device, an impact device and a rotating device are arranged on the outside of the drilling tool assembly in sequence from the front to the rear, and the rear end of the drilling tool assembly is provided with a stop Assembly, the outer end of the backstop assembly is provided with a rotary joint assembly 20, the drilling tool assembly includes a rapping rod 3, and the front end of the rapping rod is connected to a drill pipe socket 2; the impact device includes an impact function module and a reversing The control function module, the impact function module includes a cylinder liner 33, the cylinder liner is provided with a piston 4, the two ends of the cylinder liner are provided with front and rear envelopes 35, 31, and front and rear guide sleeves 34, 32 are arranged between the cylinder liner and the piston; The reversing contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com