Coal gasification device for circulating fluidized bed

A circulating fluidized bed and coal gasification technology, which is applied in the gasification of granular/powdered fuels, the manufacture of combustible gas, and the petroleum industry. It can solve complex ash discharge problems and achieve strong controllability and a large operating range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A method of coal gasification using a pressurized circulating fluidized bed. The gasification medium is introduced into the gasification medium gas inlet B at the bottom end of the riser, and the pulverized coal is added into the riser through the coal inlet D, and the pulverized coal reacts in the riser And rise into the first-stage cyclone separator, the ash and incompletely reacted coke enter the M-type return device through the first-stage cyclone separator and the first-stage feeding pipe, and the ash and unreacted coke that cannot be captured in the first-stage cyclone separator The fully reacted coke passes through the top of the primary cyclone separator and is carried by the gas into the secondary cyclone separator. In the secondary cyclone separator, the ash and incompletely reacted coke that cannot be captured in the primary cyclone separator pass through the secondary cyclone separator. The feeding pipe joins the first-level feeding pipe and enters the M-type...

Embodiment 2

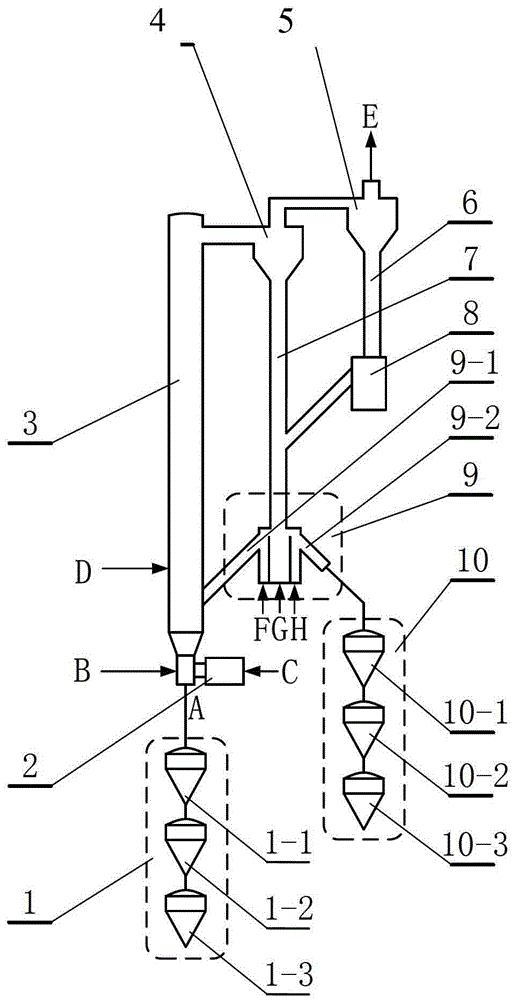

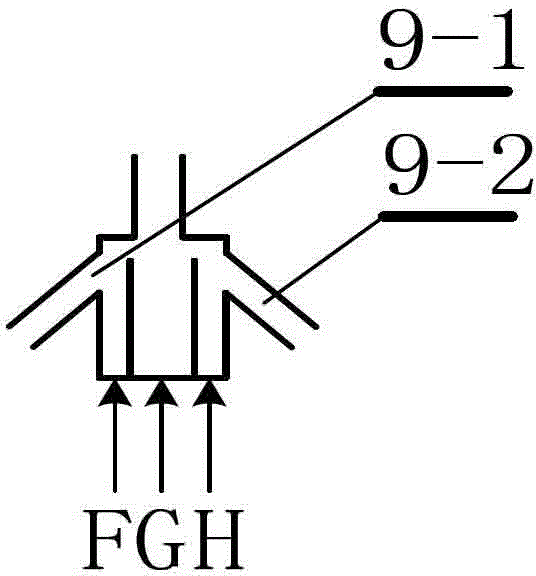

[0024] A device for coal gasification using a pressurized circulating fluidized bed. The pressurized circulating fluidized bed coal gasification device consists of a slag hopper 1, a starting combustion chamber 2, a riser 3, a primary cyclone separator 4, and a secondary cyclone separator 5 , secondary feeding pipe 6, primary feeding pipe 7, U-shaped feeder 8, M-shaped feeder 9, and ash hopper 10, the top of the slag hopper 1 is connected to the bottom of the riser 3, and the lower part of the riser 3 The side is connected with the starting combustion chamber 2, the upper part of the riser 3 is connected with the upper part of the first-stage cyclone separator 4, and the lower part of the first-stage cyclone separator 4 is continuously connected with the top of the M-type feeder 9 through the first-stage feeding pipe 7, and the M-type return Feeder 9, the two sides of M-type feeder 9 are respectively provided with return pipe 9-1 and ash discharge pipe 9-2, and one side of M-ty...

Embodiment 3

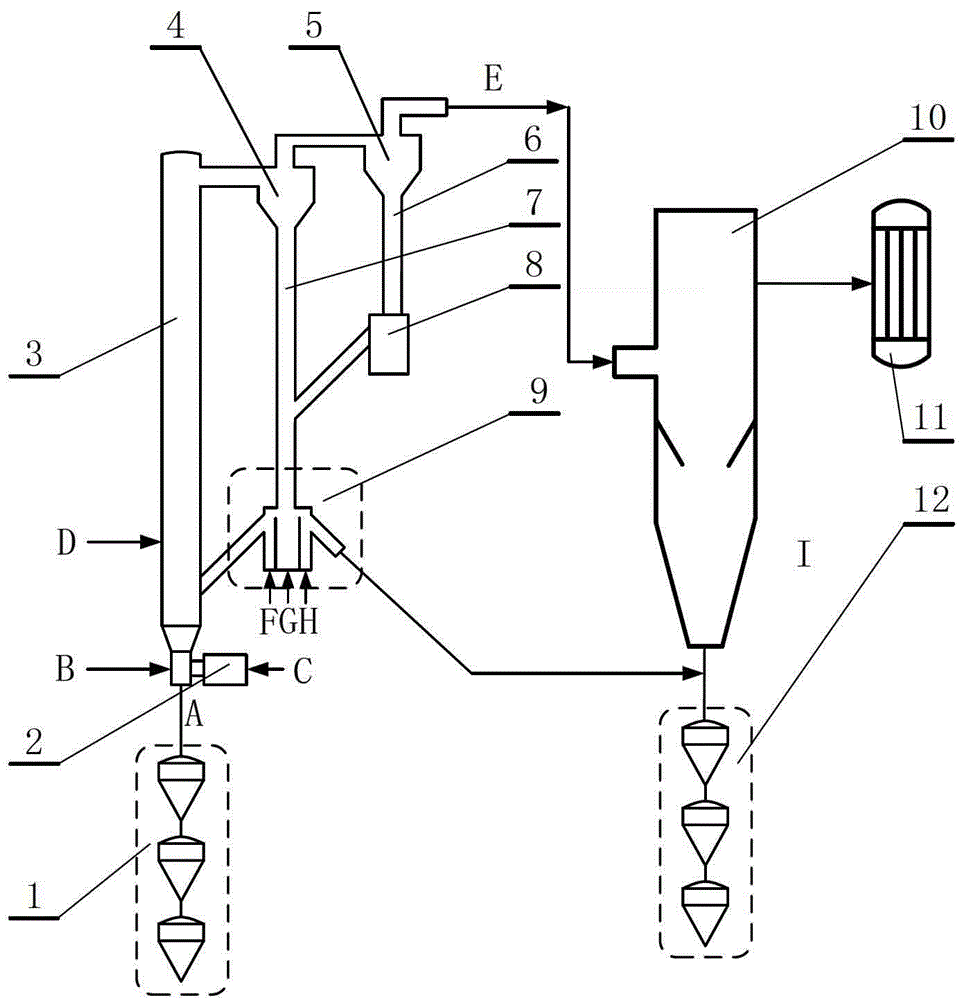

[0026] A pressurized circulating fluidized bed coal gasification method combined with a chiller, the gasification medium is introduced into the gasification medium gas inlet B at the bottom end of the riser 3, and coal slag enters through the slag discharge port A at the bottom end of the riser 3 The slag hopper, the side of the lower part of the riser 3 is connected with the start-up combustion chamber 2, the pulverized coal is added into the riser 3 through the coal inlet D, the pulverized coal reacts in the riser 3 and rises into the first-stage cyclone separator 4, and the ash and incomplete The reacted coke enters the M-type feeder 9 through the first-stage cyclone separator 4 and the first-stage feeding pipe 7, while the ash that cannot be captured in the first-stage cyclone separator 4 and the incompletely reacted coke pass through the first-stage cyclone separator 4. The top of the cyclone separator 4 is entrained by the gas and enters the secondary cyclone separator 5....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com