Hydrogenation method for activation of hydroxy-terminated butyronitrile catalyst

A liquid nitrile and terminal hydroxyl technology, which is applied in chemical instruments and methods, physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, etc. Liquid nitrile application fields, adding process steps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

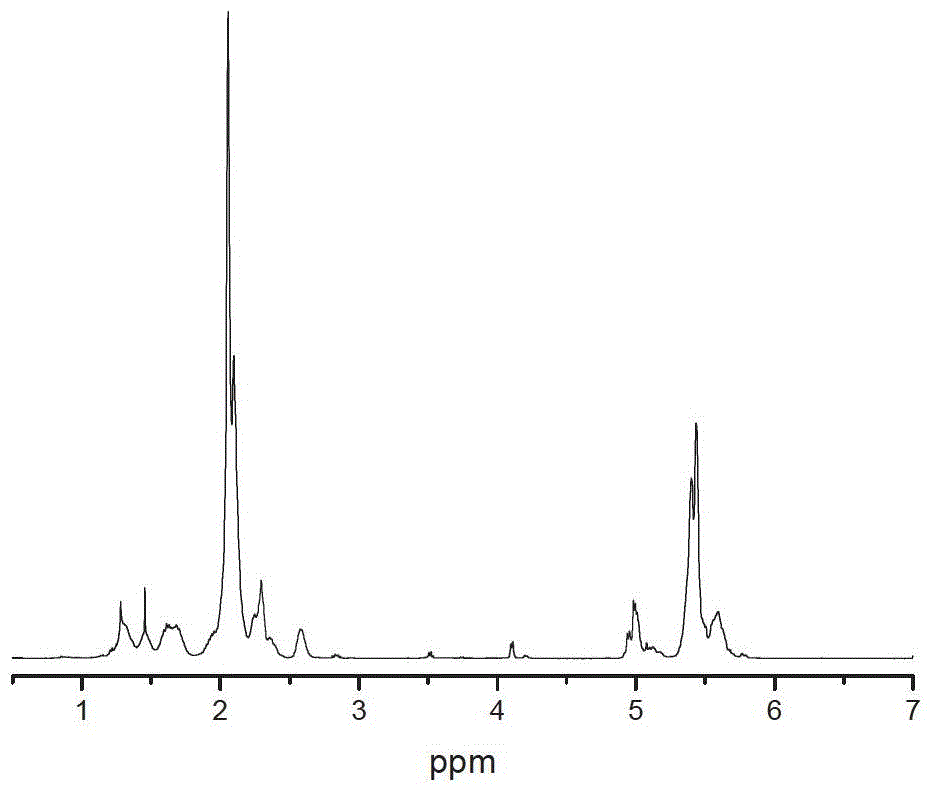

Embodiment 1-1

[0026] According to the above-mentioned general hydrogenation procedure, using hexamethyldiazide-capped liquid hydroxyl-terminated liquid butyronitrile (referred to as P-HTBN) as raw material, measure 150ML of hydroxyl-terminated liquid butyronitrile-butyronitrile xylene solution with a concentration of 16.7%, Put into a 0.5L reactor, catalyst rhodium chloride trihydrate 0.026g, cocatalyst methanol 10ml, control reaction temperature to 95°C, hydrogen pressure 3MPa, react for 6 hours, the results are shown in Table 1.

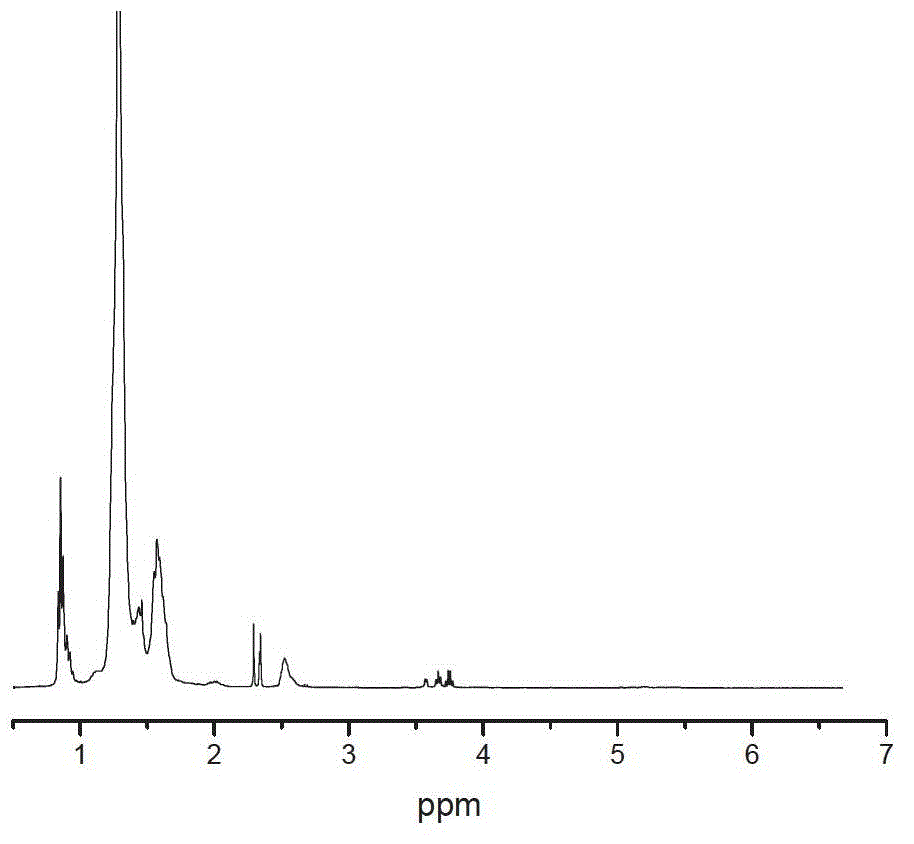

Embodiment 1-2

[0028] The raw material in Example 1-1 was changed to hydroxyl-terminated liquid butyronitrile (HTBN for short) without any capping and protection treatment, and other conditions were the same as in Example 1-1. The results are shown in Table 1.

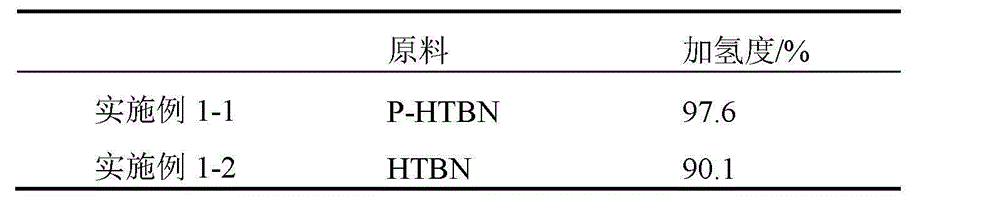

[0029] Table 1 Comparison of hydrogenation degree between P-HTBN and HTBN (with co-catalyst)

[0030]

[0031] The above examples show that the hydrogenation activity of P-HTBN is not much different from that of HTBN when the co-catalyst is added, and the addition of the co-catalyst has a significant activation effect on the catalyst.

Embodiment 2

[0041] Change the methanol in Example 1-1 to ethanol, isopropanol and acetone, and other results are the same as in Example 1-1, and the results are shown in Table 3.

[0042] Table 3 Effect of cocatalyst type on degree of hydrogenation

[0043]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com