Large-particle slow/controlled-release fertilizer with multi-layer coating structure and coating equipment of fertilizer

A slow-controlled-release fertilizer and multi-layer coating technology, applied in fertilizer forms, fertilization devices, fertilizer mixtures, etc., can solve the problem that slow-controlled-release fertilizers cannot be achieved, the sulfur coating is easy to fall off or damage, and the coating structure is easy to damage. and other problems to achieve the effect of beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

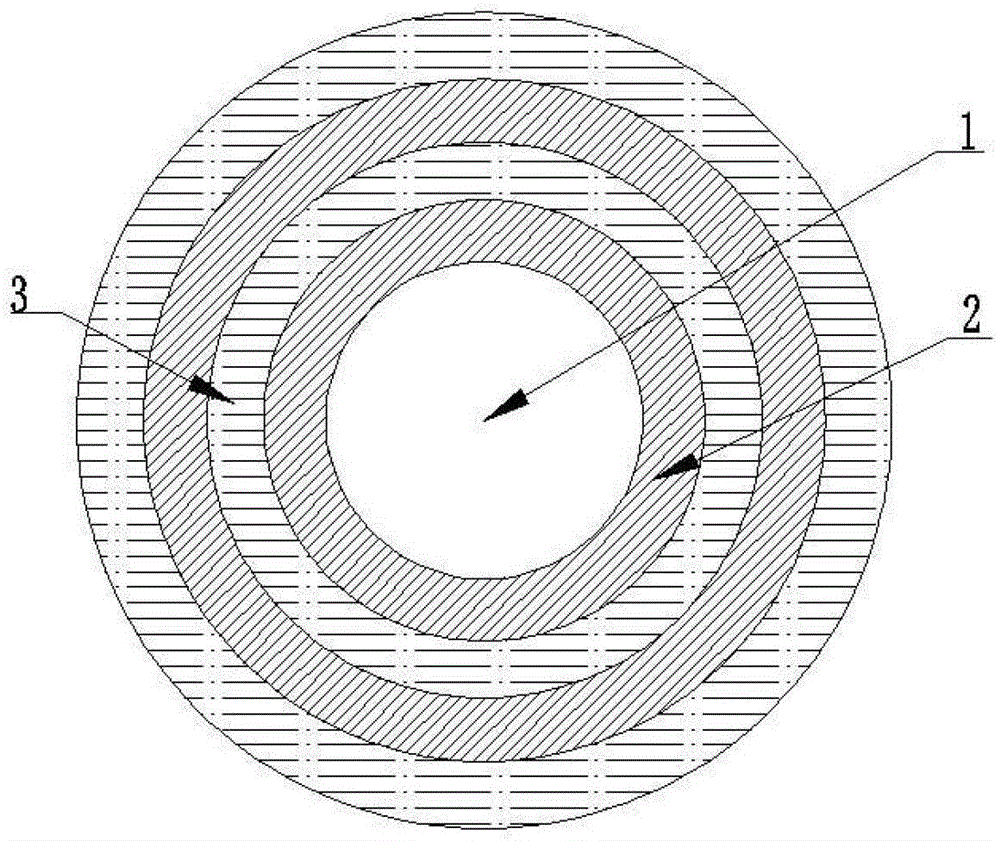

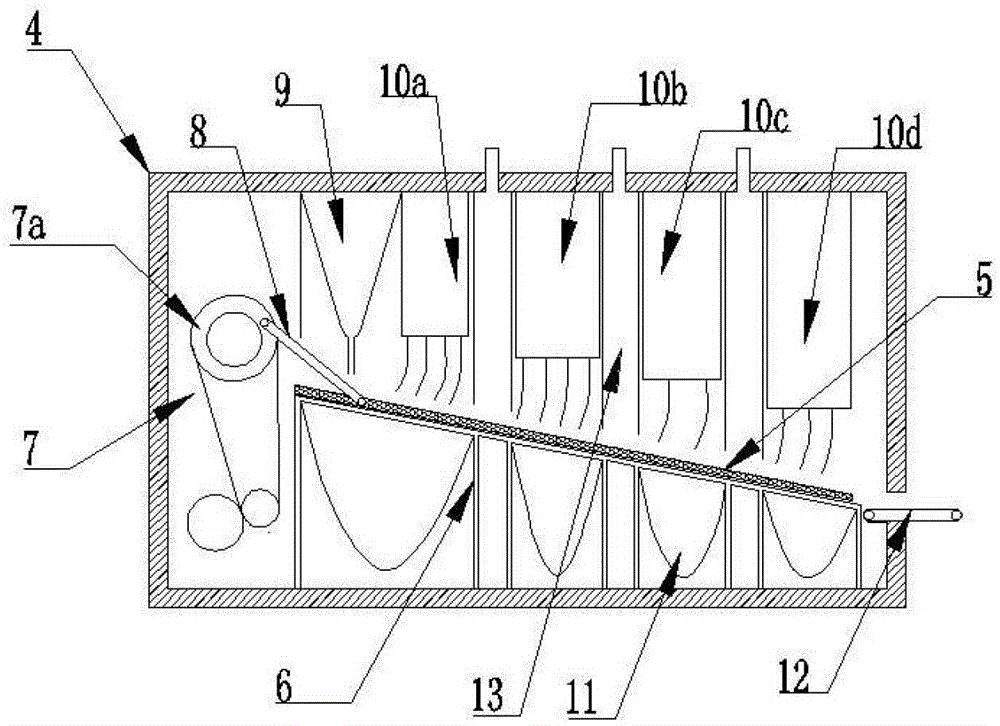

[0026] Embodiment 1: The preparation of the large particle slow-controlled release fertilizer of multi-layer coating structure of the present invention is:

[0027] 1. Preparation of Large Granular Fertilizer 1

[0028] Weigh 200 kg of urea and put it into the urea melting device to melt and keep it between 110-130 degrees, add 60 kg of monoammonium phosphate and 73 kg of potassium chloride and stir well, keep the temperature between 110-130 degrees and pour it through the filling machine Put it into a 3.5 cm spherical mold. After the mold is cooled to the shape of the fertilizer inside, open the mold to obtain spherical large particle fertilizer.

[0029] Two, the preparation of sulfur coating 2

[0030] According to parts by weight, 80 parts of sulfur, 5 parts of montmorillonite, 10 parts of microcrystalline paraffin and 5 parts of heavy oil are respectively melted and loaded into 3 spraying boxes. First add 80 parts of molten sulfur to 5 parts of montmorillonite, mix and ...

Embodiment 2

[0039] Embodiment 2: The preparation of the large particle slow-controlled release fertilizer of the multi-layer coating structure of the present invention is:

[0040] 1. Preparation of large particle fertilizer

[0041] Weigh 500 kg of urea and put it into the urea melting device to melt and keep it between 120-130 degrees, add 300 kg of 200-mesh weathered coal, add 3 kg of sodium hydroxide and stir for 20 minutes, then add 100 kg of monoammonium phosphate And 90 kg of potassium sulfate, add 5 kg of boron fertilizer, add 2 kg of zinc fertilizer and stir well, still keep the temperature between 110-130 degrees, pour it into a 5 cm spherical mold through the filling machine, and wait for the mold to cool down to the fertilizer inside After forming, the mold is opened to obtain spherical large particle fertilizer.

[0042] Two, the preparation of sulfur coating 2

[0043]With 95 parts of sulfur and 5 parts of montmorillonite in parts by weight, first melt 95 parts of sulfur a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com