High-strength colored self-leveling mortar material and its preparation method and construction method

A self-leveling mortar and high-strength technology, which is applied in the field of self-leveling mortar materials and its preparation, can solve the problems of low early strength, small application range, and single color of self-leveling mortar, achieve smooth surface, increase hydration speed, and solve single color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

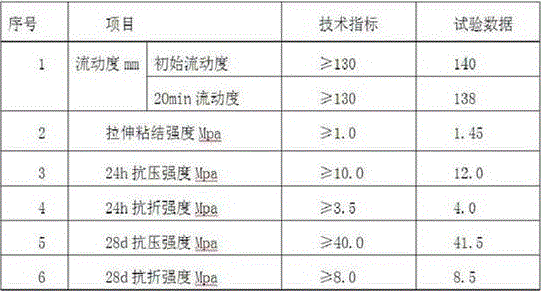

Examples

Embodiment 1

[0038] Example 1, this high-strength colored self-leveling mortar material is a powder mixed with a cementitious material and an aggregate, the cementitious material is an alkali slag cementitious material, and the aggregate is machine-made sand particles, composite external Mixtures of additives and color powder pigments;

[0039] The proportions of the alkali slag cementitious material, machine-made sand particles, composite admixtures and color powder pigments by volume percentage are as follows:

[0040] Alkali slag cementitious material 22%;

[0041] Machine-made sand particles 74%;

[0042] Compound admixture 3%;

[0043] Color powder pigment 1%;

[0044] The alkali slag cementitious material is made up of the following raw materials by weight percentage:

[0045] Slag powder 97.1%;

[0046] Water reducing agent 1.2%;

[0047] Redispersible rubber powder 0.9%;

[0048] Alkaline powder particles 0.8%.

Embodiment 2

[0049] Embodiment 2, this high-strength colored self-leveling mortar material is a powder mixed with a cementitious material and an aggregate, the cementitious material is an alkali slag cementitious material, and the aggregate is machine-made sand particles, composite external Mixtures of additives and color powder pigments;

[0050] The proportions of the alkali slag cementitious material, machine-made sand particles, composite admixtures and color powder pigments by volume percentage are as follows:

[0051] Alkali slag cementitious material 18%;

[0052] Machine-made sand particles 75%;

[0053] Compound admixture 6%;

[0054] Color powder pigment 1%;

[0055] The alkali slag cementitious material is made up of the following raw materials by weight percentage:

[0056] Slag powder 96.5%;

[0057] Water reducing agent 1.5%;

[0058] Redispersible rubber powder 1.4%;

[0059] Alkaline powder particles 0.6%.

Embodiment 3

[0060] Embodiment 3, this high-strength colored self-leveling mortar material is a powder mixed with a cementitious material and an aggregate, the cementitious material is an alkali slag cementitious material, and the aggregate is machine-made sand Mixtures of additives and color powder pigments;

[0061] The proportions of the alkali slag cementitious material, machine-made sand particles, composite admixtures and color powder pigments by volume percentage are as follows:

[0062] Alkali slag cementitious material 25%;

[0063] Machine-made sand particles 71%;

[0064] Compound admixture 3%;

[0065] Color powder pigment 1%;

[0066] The alkali slag cementitious material is made up of the following raw materials by weight percentage:

[0067] Slag powder 97.0%;

[0068] Water reducing agent 1.0%;

[0069] Redispersible rubber powder 1.0%;

[0070] Alkaline powder particles 1.0%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com