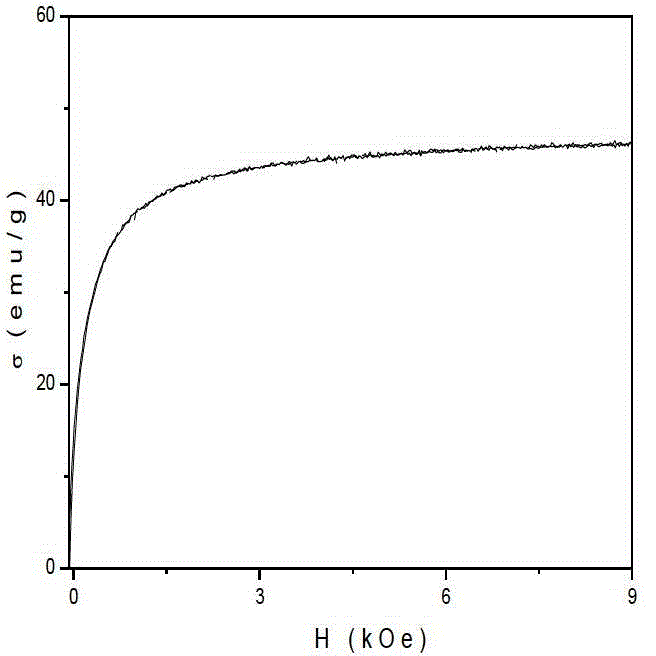

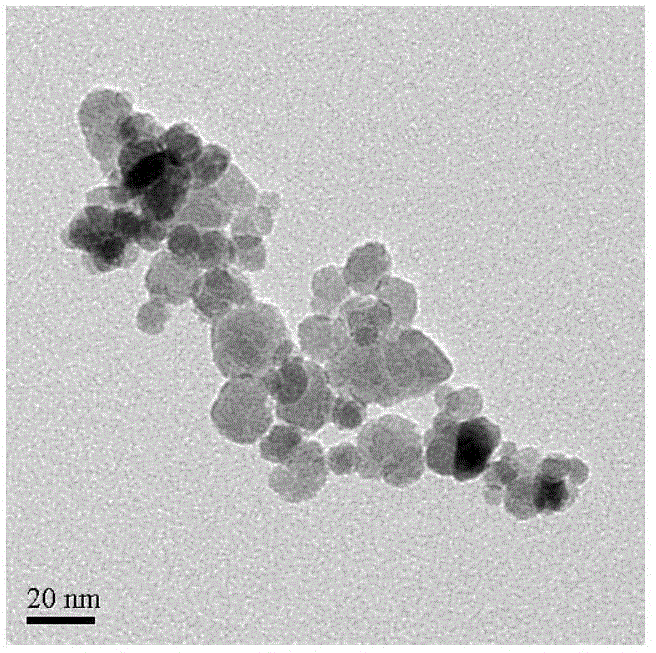

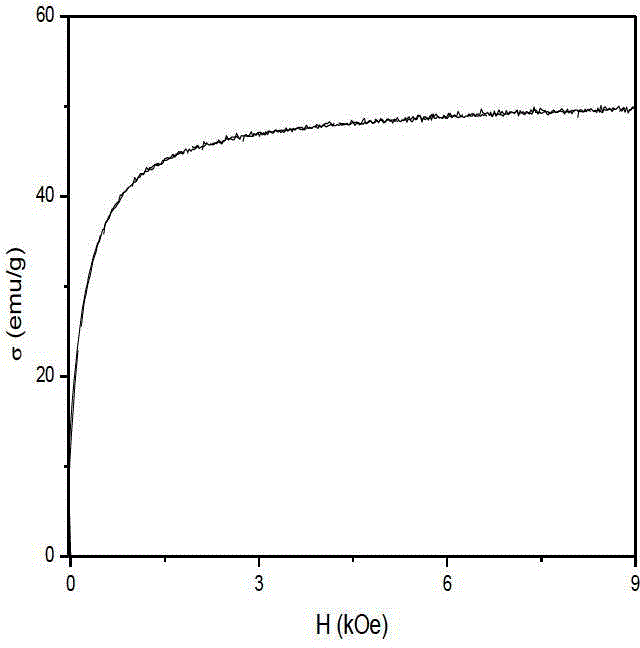

Preparation method of gamma-Fe2O3/ZnFe2O4 magnetic composite nano particle

A magnetic composite nano, -fe2o3 technology, applied in the field of nanomaterials, to achieve the effect of low raw material cost, small particle size, and easy preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] 1. Preparation of hydroxide precursor:

[0054] 1) Preparation of FeCl 3 Aqueous solution (40ml, 1mol / L) is solution a; prepare Mg(NO 3 ) 2 Aqueous solution (10ml, 2mol / L), add HCl (4.2mL, 12mol / L) to obtain solution b; prepare NaOH aqueous solution (500mL, 0.7mol / L) as solution c.

[0055] 2) Mix the solution a with the solution b to prepare FeCl 3 / Mg(NO 3 ) 2 Mixed solution, i.e. solution d;

[0056] 3) Quickly pour the solution d into the solution c under stirring to prepare the reaction solution e;

[0057] 4) Heat the reaction liquid e to boiling on the electric stove, keep boiling for 5 minutes, and then stop heating;

[0058] 5) The reaction liquid e was removed from the electric furnace, and naturally cooled to room temperature. After about two hours, the reddish-brown precipitated hydroxide precursor was completely precipitated.

[0059] 2. Preparation of Magnetic Composite Nanoparticles

[0060] 1) Preparation of FeCl 2 Aqueous solution (400mL, 0.25...

Embodiment 2

[0070] 1. Preparation of hydroxide precursor:

[0071] 1) Preparation of FeCl 3 Aqueous solution (40ml, 1mol / L) is solution a; prepare Mg(NO 3 ) 2 Aqueous solution (10ml, 2mol / L), add HCl (4.2mL, 12mol / L) to obtain solution b; prepare NaOH aqueous solution (500mL, 0.7mol / L) as solution c;

[0072] 2) Mix the solution a with the solution b to prepare FeCl 3 / Mg(NO 3 ) 2 Mixed solution, i.e. solution d;

[0073] 3) Quickly pour the solution d into the solution c under stirring to prepare the reaction solution e;

[0074] 4) Heat the reaction liquid e to boiling on the electric stove, keep boiling for 5 minutes, and then stop heating;

[0075] 5) The reaction liquid e was removed from the electric furnace, and naturally cooled to room temperature. After about two hours, the reddish-brown precipitated hydroxide precursor was completely precipitated.

[0076] 2. Preparation of Magnetic Composite Nanoparticles

[0077] 1) Preparation of FeCl 2 Aqueous solution (400mL, 0.25...

Embodiment 3

[0087] 1. Preparation of hydroxide precursor:

[0088] 1) Preparation of FeCl 3 Aqueous solution (40ml, 1mol / L) is solution a; prepare Mg(NO 3 ) 2 Aqueous solution (10ml, 2mol / L), add HCl (4.2mL, 12mol / L) to obtain solution b; prepare NaOH aqueous solution (500mL, 0.7mol / L) as solution c;

[0089] 2) Mix the solution a with the solution b to prepare FeCl 3 / Mg(NO 3 ) 2 Mixed solution, i.e. solution d;

[0090] 3) quickly pour the solution d into the solution c under stirring to prepare the reaction solution e;

[0091] 4) Heating the reaction solution e to boiling on an electric furnace, keeping boiling for 5 minutes, and then stopping heating;

[0092] 5) The reaction liquid e was removed from the electric furnace, and naturally cooled to room temperature. After about two hours, the reddish-brown precipitated hydroxide precursor was completely precipitated.

[0093] 2. Preparation of Magnetic Composite Nanoparticles

[0094] 1) Preparation of FeCl 2 Aqueous solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com