Production process of lifting handle of sticking-type packaging box

A production process and packaging box technology, applied in the field of adhesive packaging box handle production process, can solve the problems of difficult control of the source of plastic particles, difficulty in ensuring hygienic effect, and easy lateral tearing, etc., so that the source of raw materials is easy to control, The production equipment is energy-saving and efficient, and the effect is not easy to tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

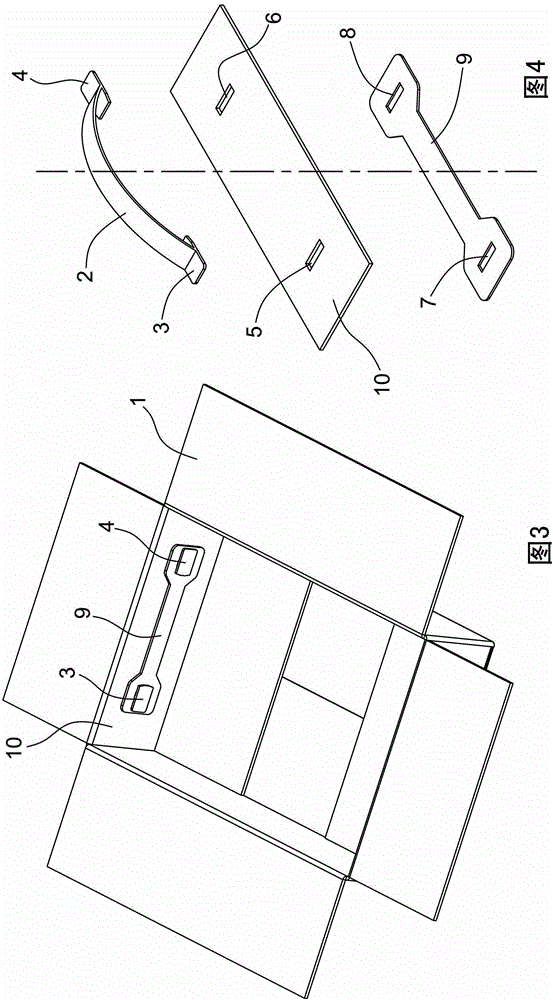

[0082] Labels in the figure

[0083] 1Packing box 2Plastic handle 3Hook 4Hook

[0084] 5 sockets 6 sockets 7 card slots 8 card slots

[0085] 9 Plastic gasket 10 Top plate 11 Inner wall surface 12 Handle body

[0086] 13 Backing 14 Backing 15 Reinforcing sheet 16 Reinforcing sheet

[0087] 17 Left end 18 Right end 19 Upper floor 20 Lower floor

[0088] 21 Box cardboard (unfolded paper box) 22 Dispenser 23 Handling robot

[0089] 24 Bottom liner punch 241 Cylinder 242 Punch rod 25 Bottom liner punch die

[0090] 26 Bottom liner punch lower die 27 Bottom liner tape feeder 271 Reel 272 Reel

[0091] 273 Pedestal 274 Pedestal 275 Reducer 276 Servo Motor

[0092] 28 Backing tape take-up 281 Reel 282 Reel

[0093] 283 Pivot Frame 284 Pivot Frame 285 Reducer 286 Servo Motor

[0094] 29 Backing Gluing Machine 291 Gluing Roller 30 Backing Tape 31 Belt Threading Machine

[0095] 32 Tape storage box 33 Handling manipulator 34 Positioning cylinder 341 Positioning punch

[0096] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com