Automatic sandblasting and derusting device between wing walls

A sandblasting and rust removal, automatic technology, applied in explosion generating devices, used abrasive treatment devices, spray guns, etc., can solve problems such as affecting workers' health, harsh working environment, low work efficiency, etc., and reduce scaffolding construction. Work, save sandblasting labor, high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

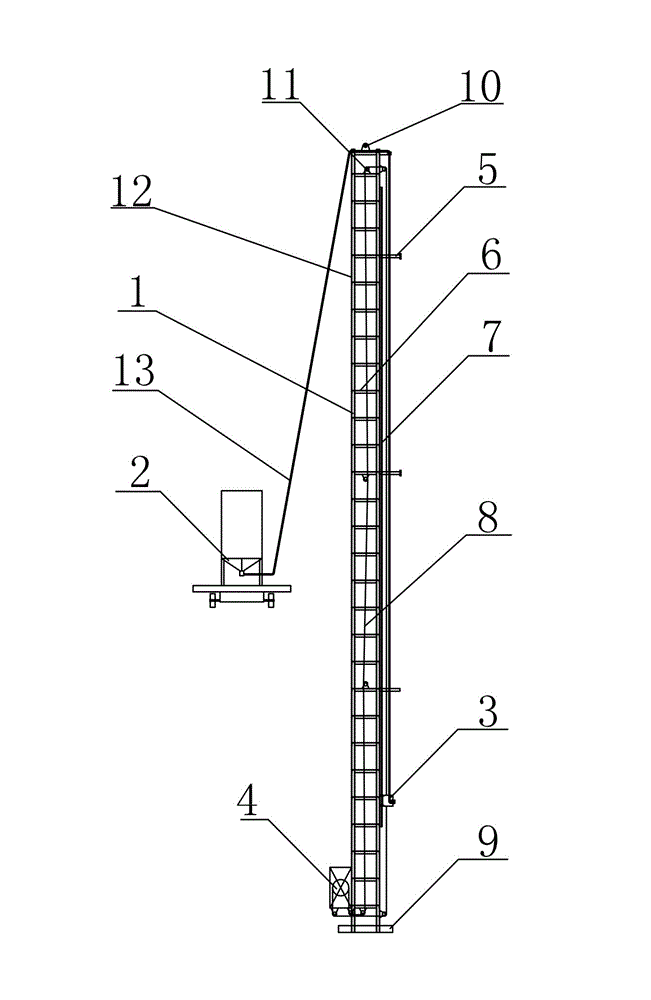

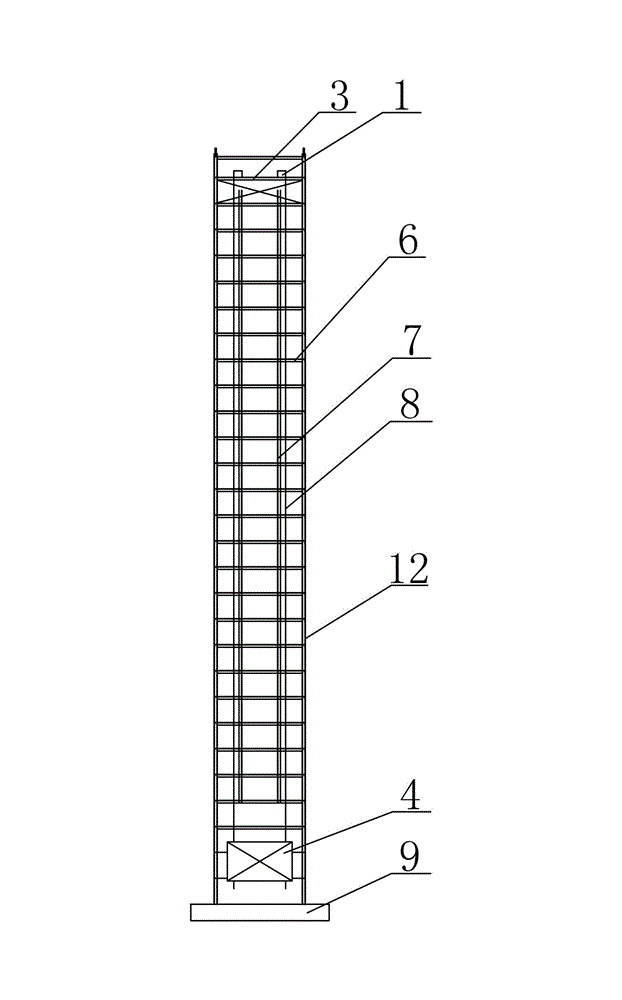

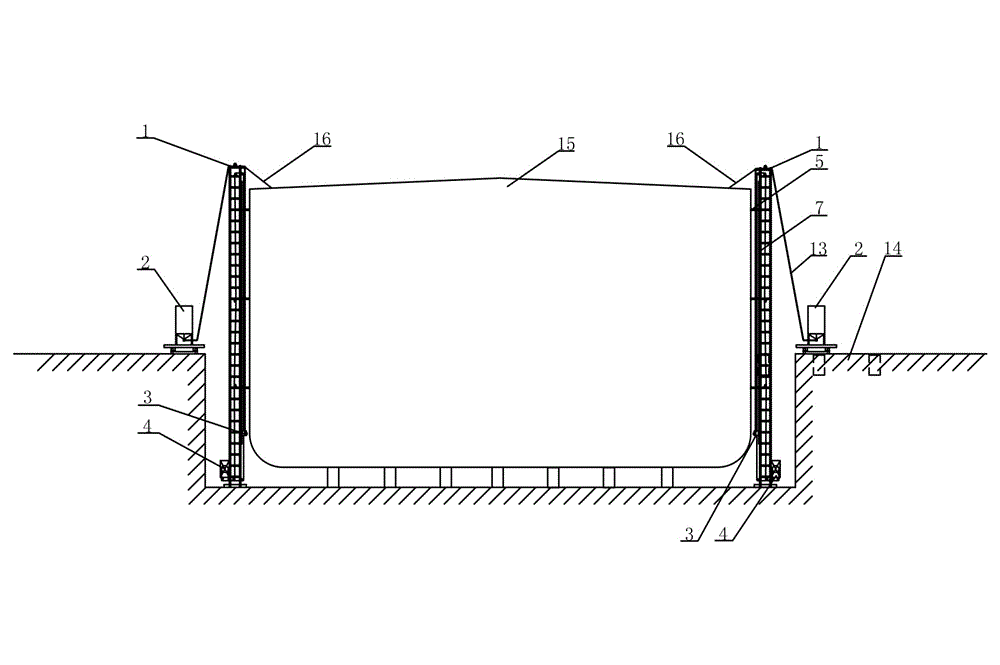

[0013] See attached figure 1 ~ attached figure 2 , the present invention is made up of frame 1, sandblasting machine 2, sandblasting trolley 3 and elevator 4, and described frame 1 is that four square steel upright columns 12 that are arranged on the base 9 are welded with several transverse supports 6 Frame structure, the top of which is provided with lifting lugs 10, two rails 7 and several supporting feet 5 are arranged on one side of the frame 1, the rails 7 are fixed on the horizontal support 6 and parallel to the frame 1, and several supporting feet 5 Fixedly arranged on two columns 12 and perpendicular to the columns 12; the elevator 4 is fixedly arranged on the base 9 on one side of the frame 1; the sandblasting trolley 3 is a mobile sandblasting gun arranged on the track The sand gun is connected with the sand tank of the sandblasting machine 2 by a hose 13, and the upper and lower ends of the sandblasting trolley 3 are connected with the elevator 4 by a steel wire ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com