Method for manufacturing trench cover plate

A manufacturing method and technology of trench cover plates, which are applied in the field of manufacturing stainless steel trench cover plates, can solve problems such as easy corrosion of cover plates, requirements for temperature and pressure, and cumbersome steps, etc., and achieve tight arrangement, prevent pollution, and process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

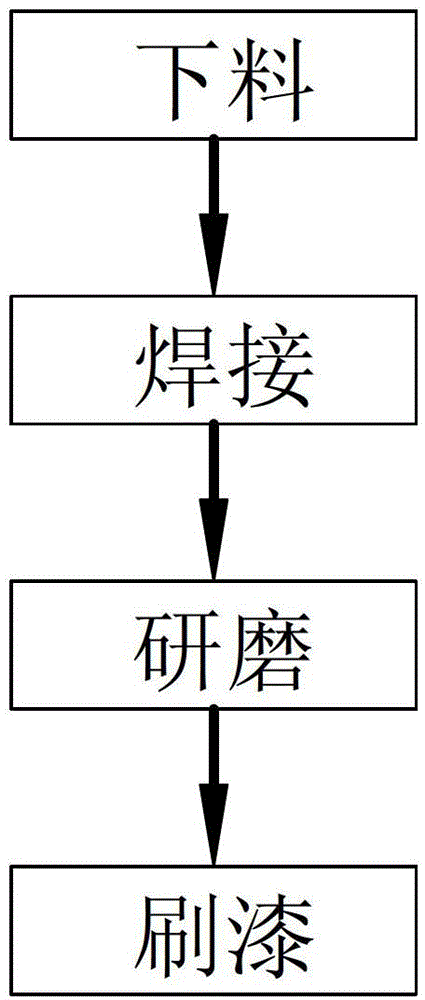

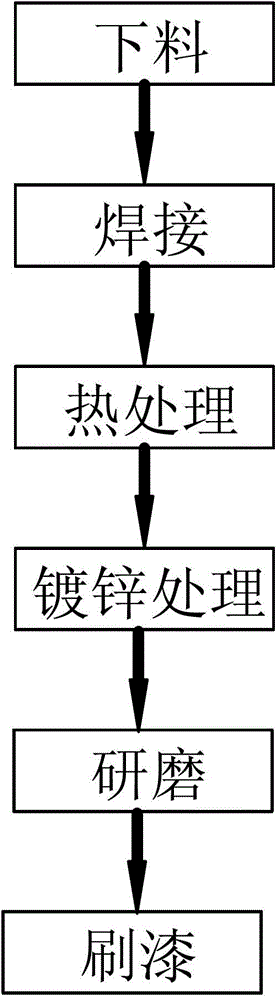

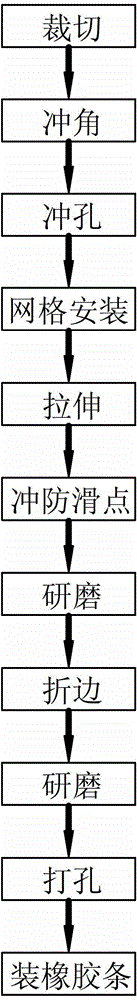

[0031] A kind of manufacture method of trench cover plate provided by the present invention, its steps are:

[0032] When cutting the material, use a steel tape to measure and check the size when receiving the stainless steel plate to see if it is the required specification.

[0033] Then enter the cutting process, adjust the numerical control size with the shearing machine, check the required stainless steel plate size again, and cut the stainless steel plate into the required specifications according to the length direction.

[0034] Then enter the punching angle process, first adjust the size of the punching angle mold, check the size and need to measure twice, after confirming that it is correct, start punching the angle. At the same time, check whether there is a burr at the punching angle. If the burr is within the normal tolerance range, continue; if it exceeds the tolerance range, stop and adjust the mold gap.

[0035] Then enter the punching process, select the requi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com