Sealant overflow process of photovoltaic assembly framing

A photovoltaic module and framing technology, which is applied in the direction of electrical components, semiconductor devices, sustainable manufacturing/processing, etc., can solve the problems of increasing the workload of the sealant 3, unstable overflow of the sealant 3, and unstable vertical turning transition. To prevent the sealant from overflowing unsteadily, save the process of cleaning the sealant, and avoid the effect of manual glue filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0037] A glue overflow process for a photovoltaic module group frame, which includes the following process steps:

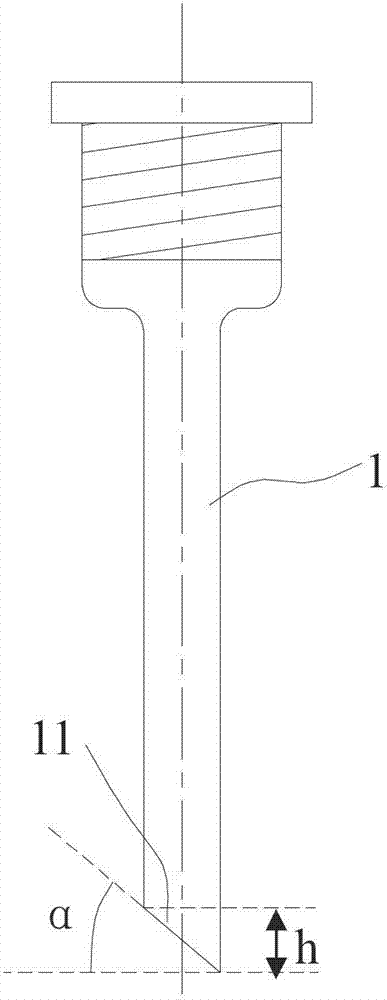

[0038] (1) if Figure 8-Figure 11As shown, the sealant 3 is injected into the installation groove 21 of the frame 2 with the glue injection head 1, wherein the outlet of the glue injection head 1 has a tip, and the tip is formed by the intersection of the platform 12 and the inclined surface 11, and the clamping of the inclined surface 11 and the platform 12 The angle β is 80°, and the height h of the inclined surface 11 is 7 mm; in this embodiment, glue is produced by connecting the glue machine to the glue injection head 1, or the glue can be injected manually through the glue injection head 1; the frame 2 adopts the application number of The utility model patent of 201120475537.5 discloses a frame with installation g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cross-sectional area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com