Method for automatically adjusting back focal length (BFL) of unthreaded lens based on inverse projection mode

An automatic adjustment and reverse projection technology, applied in the direction of optical components, instruments, optics, etc., to achieve the effect of ensuring consistency and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

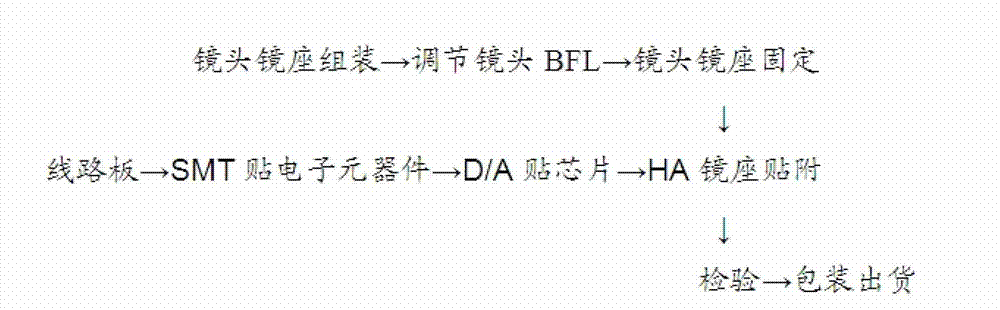

[0034] attached figure 1 In order to utilize the work flow implemented by the present invention, first assemble the lens base, clean and assemble the lens base before adjusting the lens BFL; after adjusting the lens BFL, fix the lens base, and at the same time carry out circuit board → SMT paste electronic components → The process of D / A chip attaching → HA mirror holder attaching can be inspected, packaged and shipped at this time.

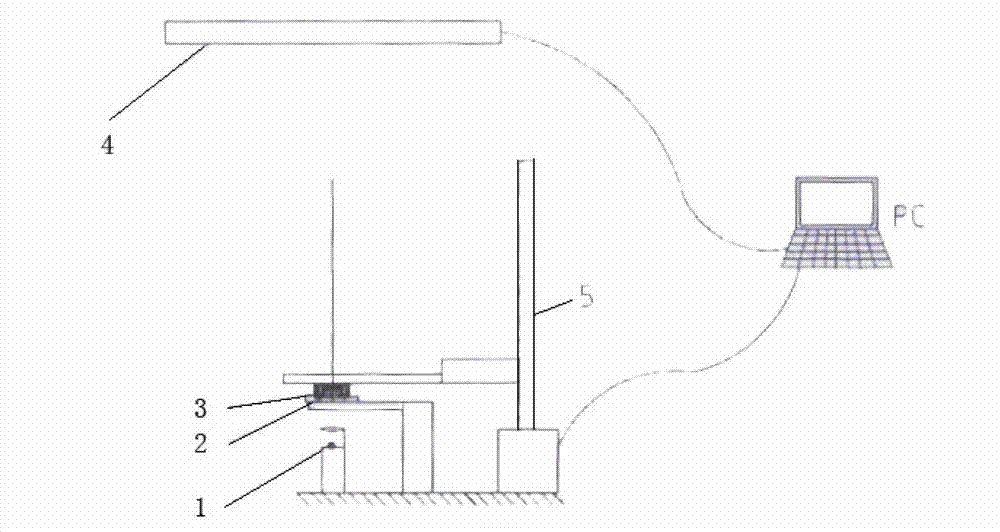

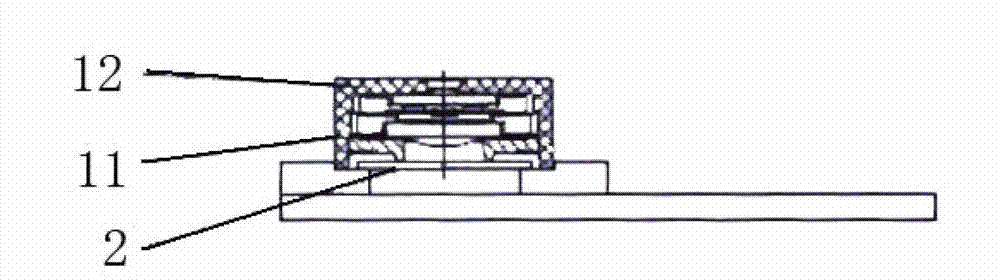

[0035] as attached figure 2 And attached image 3 , a machine for automatically adjusting the lens BFL, including a parallel light source device 1, a standard plate 2, an image sensor 4, and a linear motion execution system 5, the parallel light source emitted by the parallel light source device 1 can be irradiated to the image sensor 4 through the standard plate 2, The lens mount group 3 is placed above the standard plate 2, the linear motion execution system 5 and the image sensor 4 are respectively connected to the PC through data lines, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com