Solar dryer

A solar collector and dryer technology, which is applied to solar collectors, solar thermal energy, solar thermal power generation, etc., can solve the problems of low thermal conductivity of hot air, reduced thermal efficiency, and insufficient utilization of heat.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

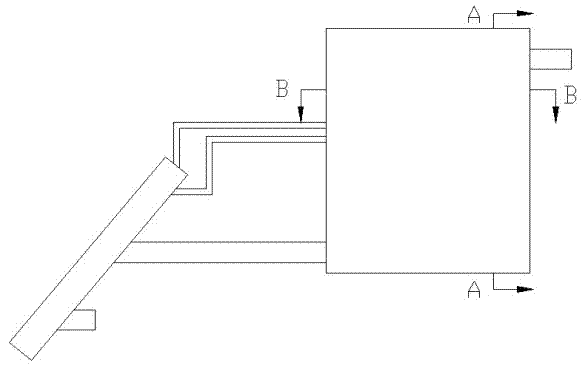

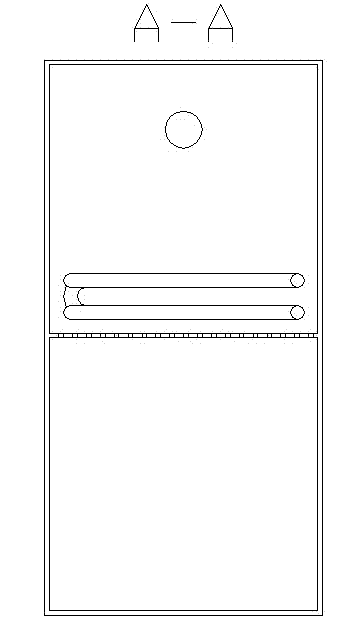

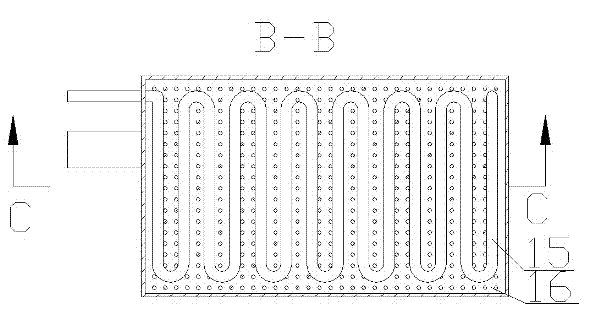

[0020] The embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0021] In the case of sufficient sunlight, the low-boiling-point heat-conducting medium in the serpentine elbow 7 absorbs heat and vaporizes, and flows into the heat-dissipating pipe 15 at high speed along the pipe through the outlet nozzle 1 and the medium ascending pipe 9, and releases heat to liquefy. After liquefaction The medium flows back to the serpentine elbow 7 through the medium return pipe 10 and the liquid inlet nozzle 2. The blower fan 13 starts, and air is sucked into the front chamber 17 of the heat collector from the air inlet pipe 5, passes through the porous heat absorbing plate 8 to absorb heat, becomes hot air and enters the drying chamber through the air outlet pipe 4 and the air inlet pipe 11. The dried objects are stacked on the perforated plate 16 , and the heat release pipe 15 is covered to absorb heat from the heat release p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com