Safety burning torch with vertical movement type push button

A safety point and mobile technology, applied in the field of safety point guns, can solve the problems of triggering the safety distance and losing the function of safety, so as to achieve the effect of improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

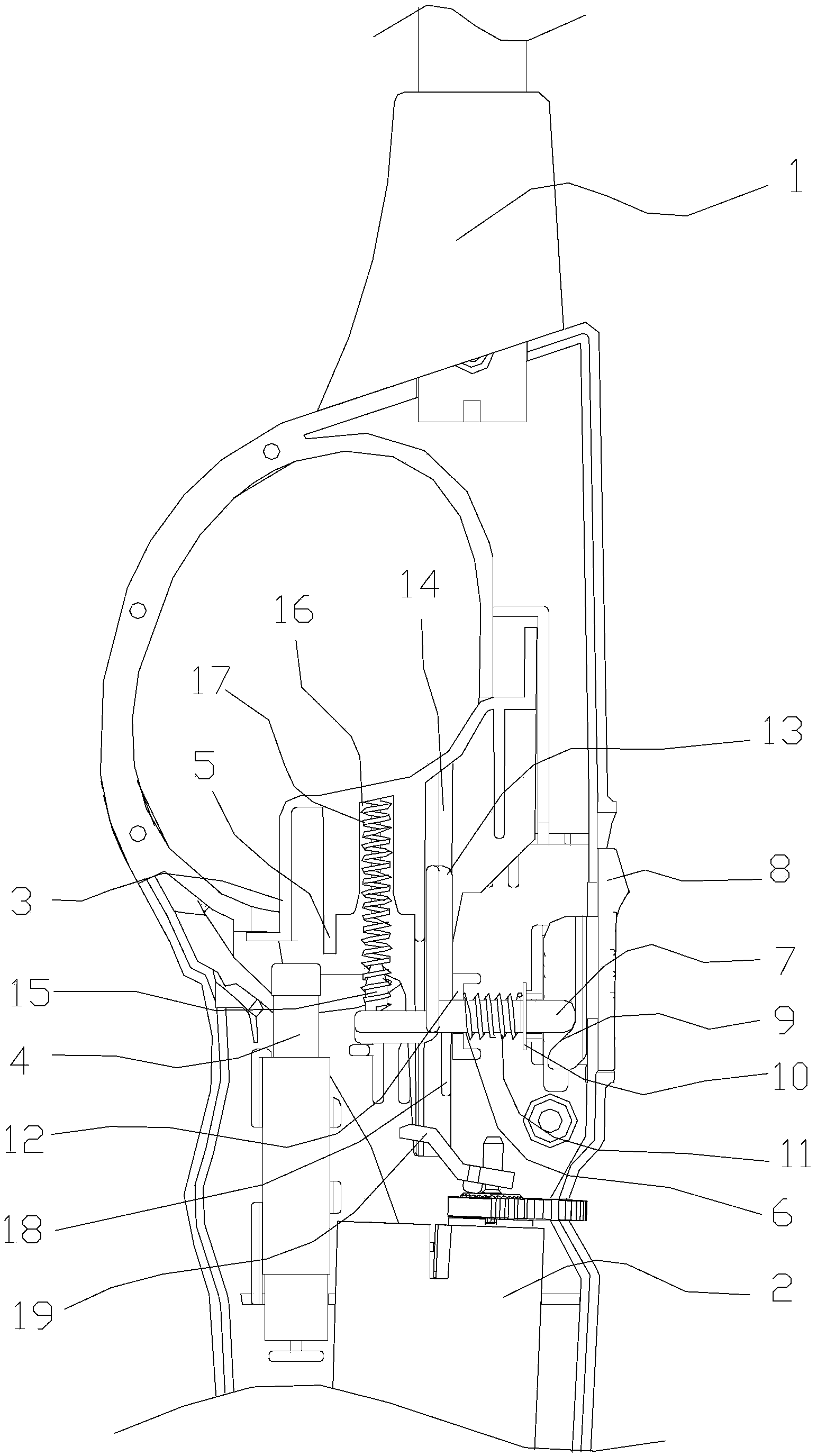

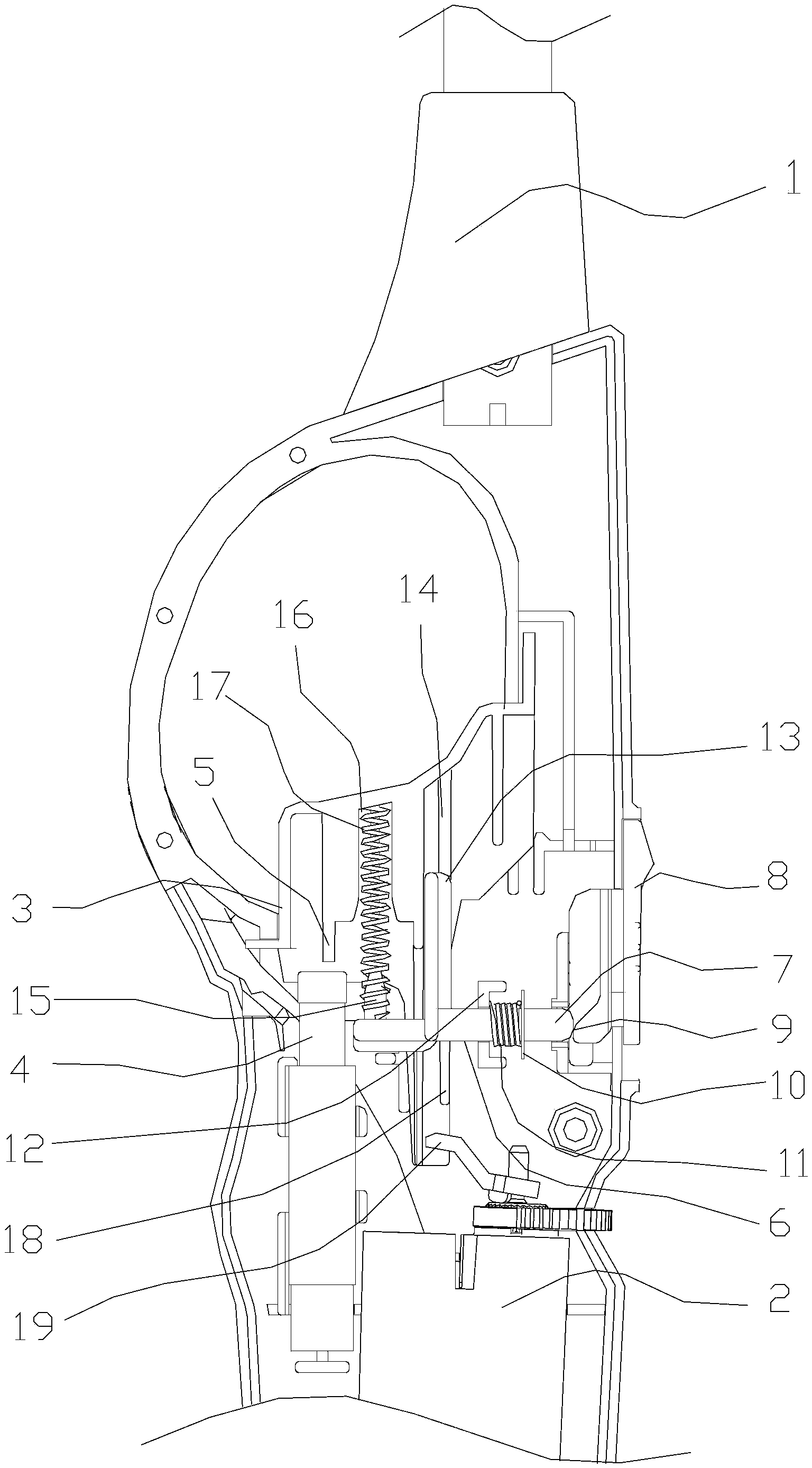

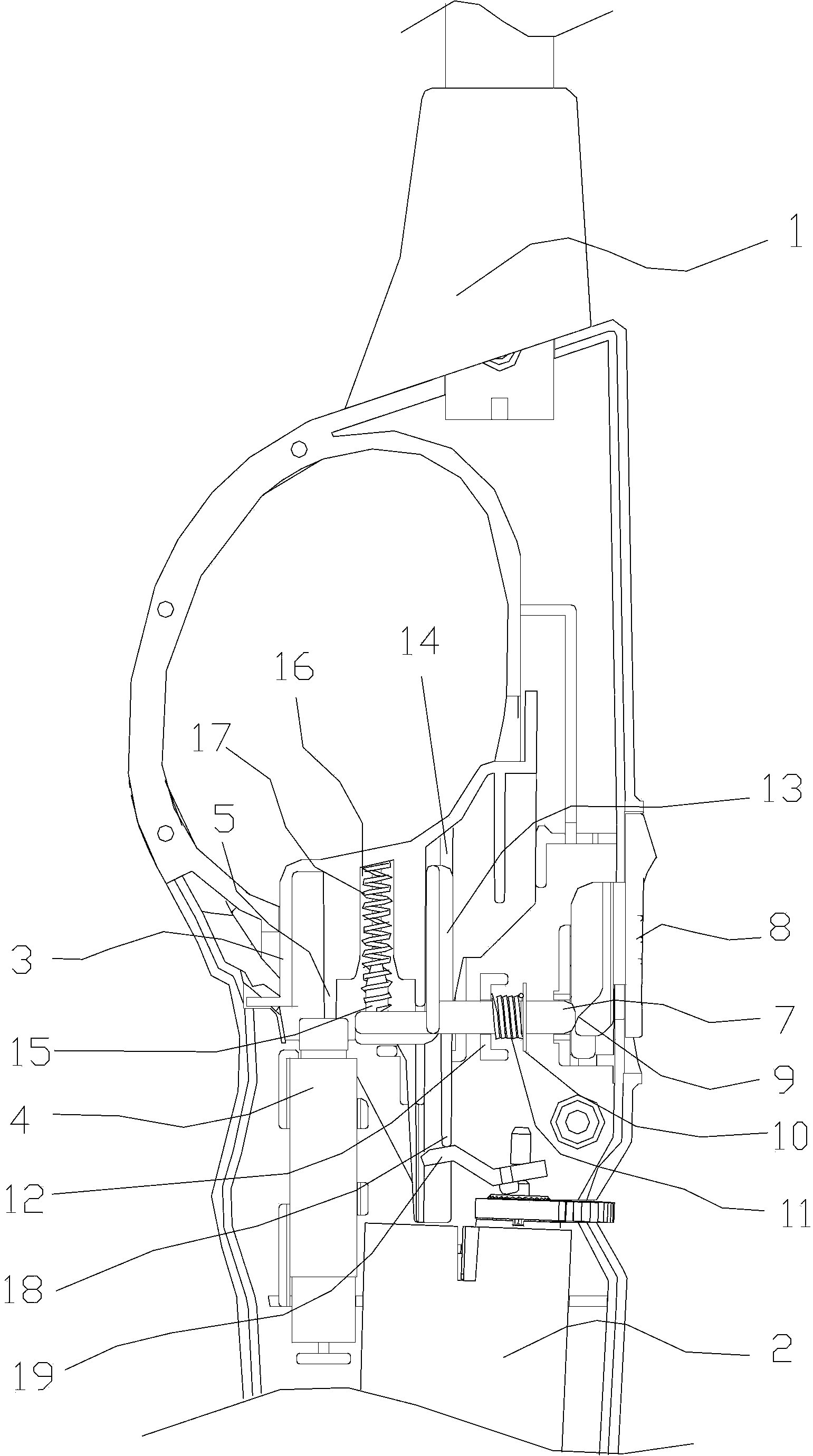

[0020] Such as Figure 1-3 As shown, a safety ignition gun with an up and down movable push button described in this embodiment includes a gun body 1, an oil tank 2 placed in the gun body, a crowbar 19 and a piezoelectric 4 installed on the oil tank, and the gun body 1 A vertically slidable pressing hand 3 is installed on the top, and the inner wall of the pressing hand 3 forms a convex working part 5 which is dislocated with the upper end of the piezoelectric under normal conditions. The inner wall of the pressing hand 3 and the upper end surface of the piezoelectric 4 There is a safe distance between the pressing hand 3 and a slide block 6 that makes it move laterally when the pressing hand is pressed down under normal conditions, and the piezoelectricity cannot be excited to generate high-voltage electricity. The push button end of slide block 6 forms a transverse part 7, and the outside of described transverse part 7 is provided with a push button 8 that can shift up and d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com