Soot blower for chamber-combustion water tube pulverized coal fired boiler

A pulverized coal boiler and soot blower technology is applied in the combustion method, combustion product treatment, and solid residue removal. Use reliable effects

Inactive Publication Date: 2013-01-30

YIXING TIANDI ENERGY SAVING TECH

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The main purpose of the present invention is to provide a soot blower for a chamber-fired water tube pulverized coal boiler. Scaling affects the technical problems of boiler heat exchange capacity

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

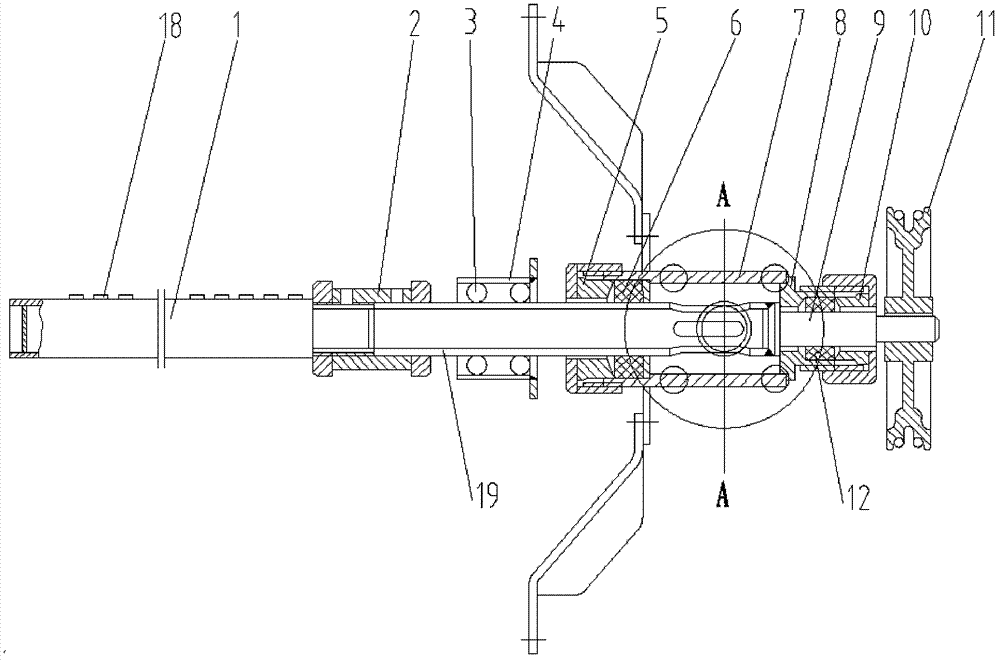

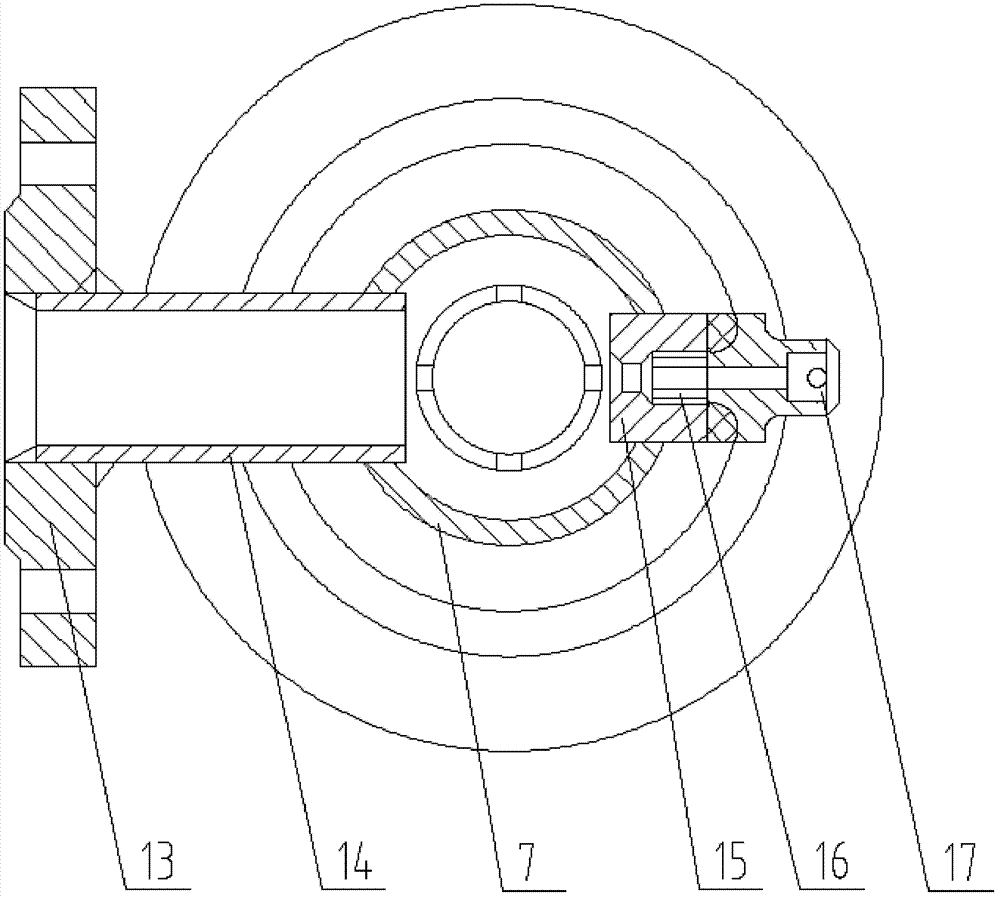

A soot blower for a chamber-combustion water tube pulverized coal fired boiler comprises a soot blowing tube, a joint ring, asbestos ropes, a seamless steel tube sleeve, a front pressing cover, front padding, a seamless steel tube shell, a shaft, a rear pressing cover, a sprocket, rear padding and a middle tube. The soot blowing tube is connected with the joint ring through the middle tube, the front of the middle tube is provided with the seamless steel tube sleeve, the middle of the middle tube is connected with the chamber-combustion water tube pulverized coal firing boiler through the seamless steel tube shell, the front padding is disposed between the seamless steel tube shell and the middle tube, the front padding is provided with the front pressing cover at the front end, the seamless steel tube shell is connected with the shaft at the rear end, the shaft is provided with the rear pressing cover, and the shaft is provided with the sprocket at the tail end. The soot blower of the chamber-combustion water tube pulverized coal firing boiler is simple in structure, reliable to use and thoroughly effective in soot blowing, the defect of soot deposition caking on the outer surface of a convection tube bundle can be overcome thoroughly.

Description

technical field [0001] The invention relates to a soot blower, in particular to a soot blower for a chamber-fired water tube pulverized coal boiler. Background technique [0002] At present, traditional pulverized coal boilers and water-tube steam boilers generally have the disadvantages of high energy consumption, high power consumption, high smoke and dust emissions, and low thermal efficiency, and continue to undergo technological transformation and upgrading. [0003] Traditional chamber-fired water-tube pulverized-coal boilers are prone to ash scaling on the outer surface of the convection tube bundles, affecting the heat transfer capacity of the boiler. Therefore, a soot blower is urgently needed to solve the above problems. Contents of the invention [0003] The main purpose of the present invention is to provide a soot blower for a chamber-fired water tube pulverized coal boiler. Scaling is a technical problem that affects the heat exchange capacity of boilers. ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F23J3/02

Inventor 吴优君吴侠

Owner YIXING TIANDI ENERGY SAVING TECH

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com