Self-balancing water-seal-type anti-explosion device

A technology of water seal and explosion-proof device, applied in the direction of dust prevention, fire prevention, gas discharge, etc., can solve the problems of lack of water cover, increase system resistance, large gas flow, etc., achieve sufficient separation of steam and water, reduce separation burden, avoid The effect of blocking the pipeline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

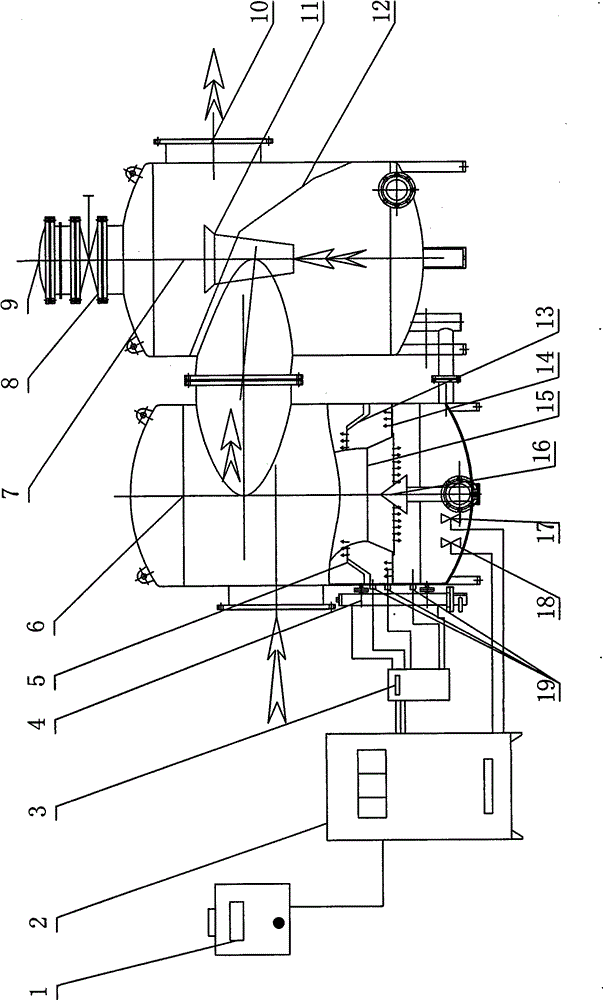

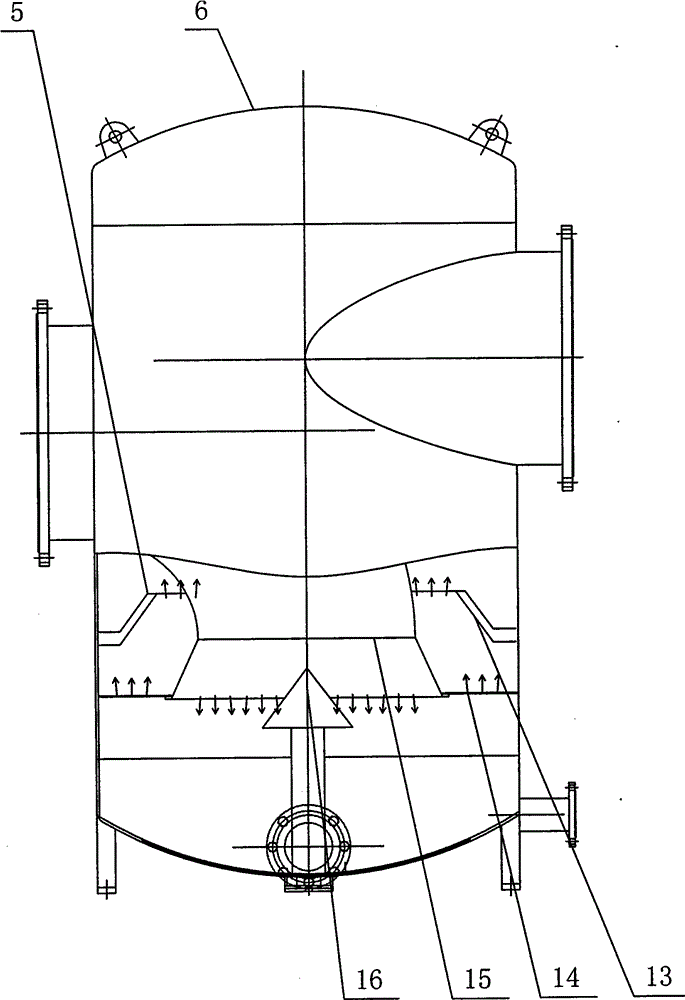

[0019] Such as figure 1 with figure 2 As shown, the self-balancing water-sealed explosion-proof device of the present invention is composed of three parts: a water-sealed device, a steam-water separation explosion-venting device and an intelligent water level monitoring device. In the gas drainage system, the high-speed gas enters the water sealer through the connecting pipeline, passes through the primary gradual expansion speed reduction device 15 in the water sealer, enters the sealing water, and enters the second time through the anti-splash barrier 14. The gradual expansion speed reduction device 5, through the ring-shaped muffler 13, the water in the water sealer enters the steam-water separation explosion venting device driven by the high-speed gas gas, and the water and the gas gas are separated by the principle of centrifugal separation, and the gas gas flows from the The exhaust port 10 enters the drainage system, and the separated water is led back into the water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com