Metal surface salt bath nitrocarburizing method

A technology of nitrocarburizing and metal surface application in the direction of metal material coating process, coating, solid-state diffusion coating, etc., which can solve the problems of low efficiency, inability to guarantee the quality of nitrocarburizing of parts, and failure to keep up with the increase of cyanide Speed and other issues to achieve the effect of reducing pollution and improving regeneration capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

[0046] The method for the metal surface salt bath nitrocarburizing of the present embodiment comprises the following steps:

[0047] ① Cleaning of the workpiece. First check the surface of the workpiece to be infiltrated. If there is a decarburized layer, rust spots, sharp corners or sharp edges, it must be polished first, and then cleaned if there is no such situation by visual inspection.

[0048] When the workpiece is cleaned, first remove the oil stain on the surface by alkali washing, soak in clean water after alkali washing, rinse to remove the surface cleaning solution, and then dry it at 100°C to check the cleanliness of the workpiece surface and complete the cleaning to be processed.

[0049] During the cleaning process, for workpieces with blind holes or internal and external threads, the blind holes or threads need to be carefully inspected and cleaned.

[0050] ②Clamping of the workpiece. Install the cleaned workpiece obtained in step ① on the fixture to ensure t...

Embodiment 2)

[0084] The rest of the method of the metal surface salt bath nitrocarburizing of the present embodiment is the same as that of embodiment 1, the difference is: in the nitrocarburizing process of step ④, the sulfur-containing compound added in the salt bath furnace is The dosage of potassium sulfate and potassium sulfite is 2×10 of the quality of the salt bath in the salt bath furnace -2 %~4×10 -2 %.

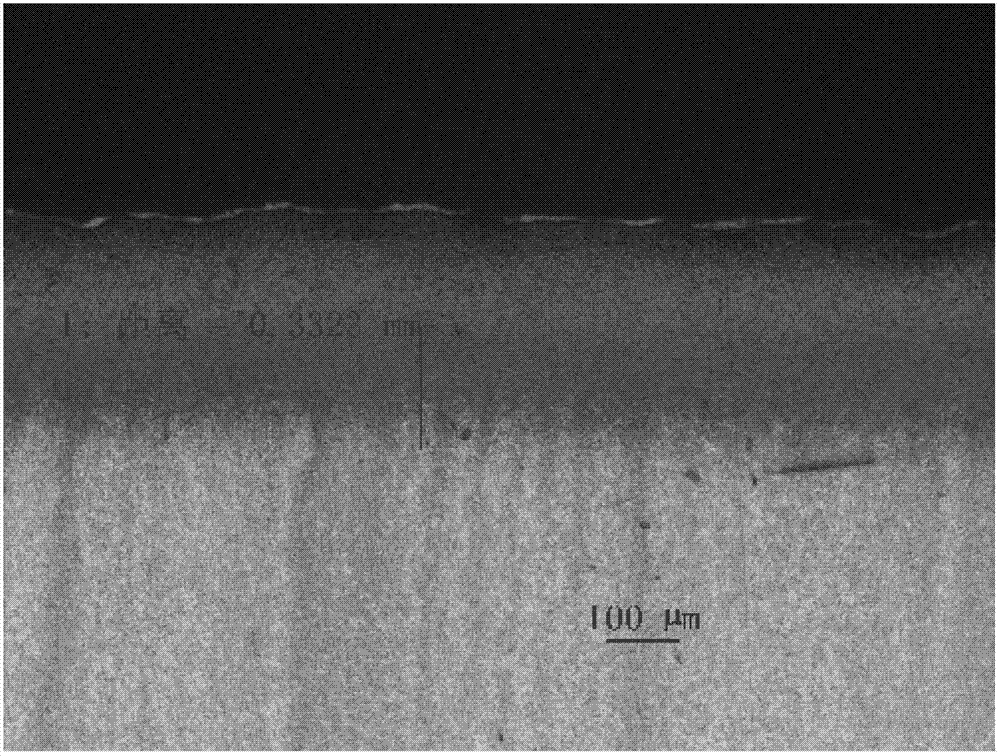

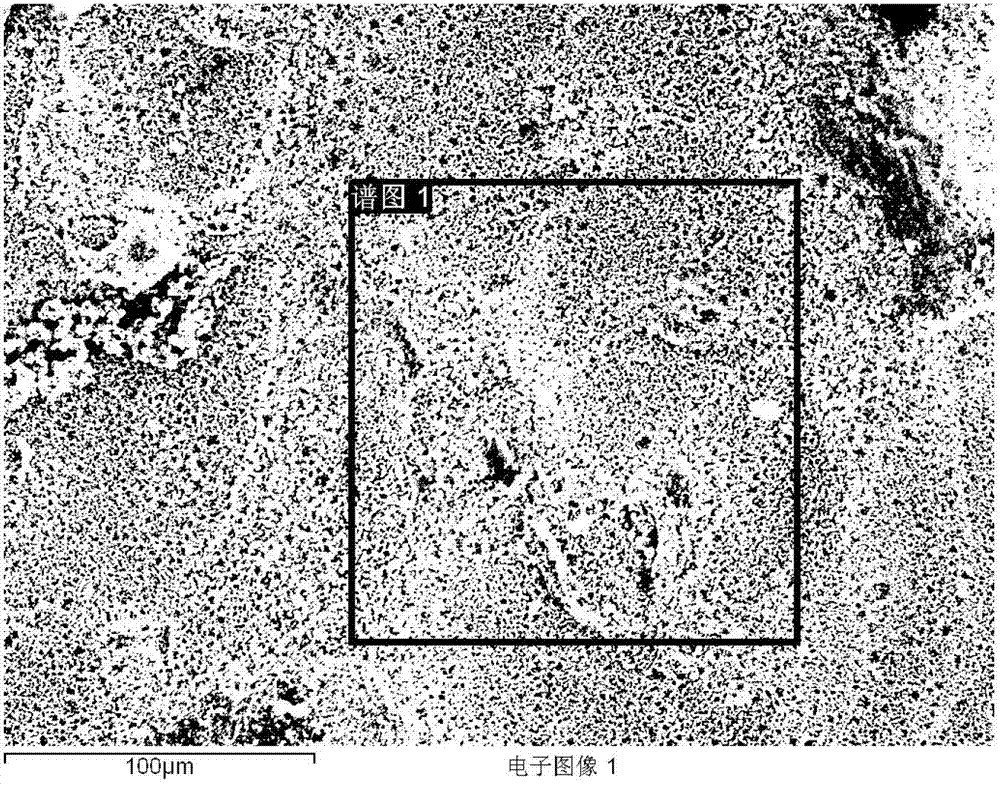

[0085] S-3700N electron scanning microscope (voltage 20Kv, current 102μA, working distance 10mm) carried out elemental analysis on the nitrided layer of the co-infiltrated parts after adding sulfur-containing compounds, and there was no infiltration of sulfur element.

Embodiment 3 to Embodiment 6)

[0087] The rest of the method of salt-bath nitrocarburizing of metal surfaces in Examples 3 to 6 is the same as in Example 1, except that the corresponding sulfur-containing compounds and corresponding dosages listed in the following table are used.

[0088]

[0089] S-3700N electron scanning microscope (voltage 20Kv, current 102μA, working distance 10mm) carried out elemental analysis on the nitriding layer of the co-infiltrated parts after adding sulfur-containing compounds in the above-mentioned embodiments, and found no infiltration of sulfur element.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com