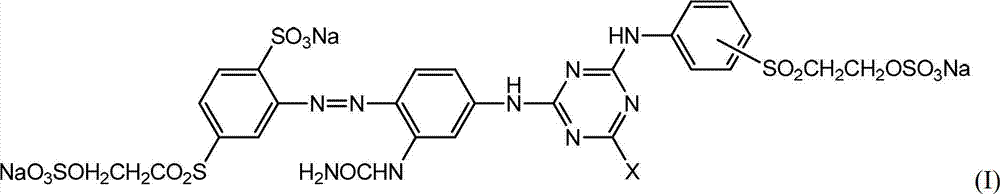

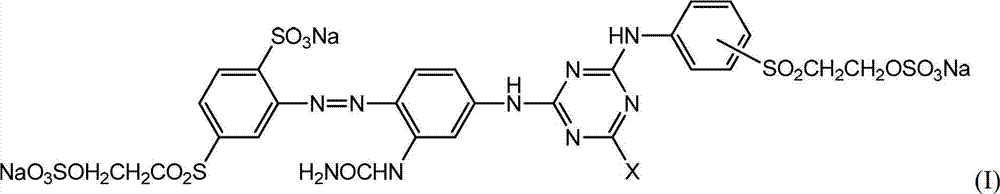

Composite reactive yellow dye and preparation method thereof

A reactive yellow and dye technology, applied in the field of dyes, can solve the problems of poor compatibility of navy blue and red dyes, low dye fixation rate, unfavorable dyeing of dark colors, etc., and achieves bright colors, high solubility, and good salt and alkali resistance stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] a) Beat 1.0 mole of sulfonated meta-ester with ice water for 0.5 hours, add 2 moles of hydrochloric acid, add 1.01 moles of 30% sodium nitrite solution, keep the temperature at 0-5°C, and keep the Congo red test paper showing blue and starch during the addition process Potassium iodide test paper is blue under the microscope, keep the conditions for reaction for 1 hour, balance the slightly excess nitrous acid with sulfamic acid, and control the volume to 5000ml / mol to obtain the diazonium salt.

[0022] b) Add 1.0 mole of m-urea amidoaniline to the balanced diazonium salt and stir well, adjust the pH to 4.5~6.5 with soda ash solution, keep the pH value, and react for 2 hours at a temperature of 5-8°C to obtain a coupling The reaction solution.

[0023] c) Beat 1.02 moles of cyanuric chloride in ice water for 45-60 minutes, control the temperature at about -1-1°C, add the coupling reaction solution after beating, and adjust the pH to 6-6.5 with soda solution at a temper...

Embodiment 2

[0027] Change the para-ester component in the secondary condensation reaction of Example 1d) to meta-ester, use dry baking soda to keep the pH at 2.5~3.5, raise the temperature to 45°C in 1-1.5 hours, adjust the pH to 5.5~6.0 and react for 6 hours, The pH is stable, and the pH is adjusted to 6.0~6.5, which is used for concentration and purification of nanofiltration membranes.

[0028] Mix according to the mass ratio of 30.70 after folding, add a total amount of 10% sodium sulfate, and 2% dustproof agent, and spray dry to obtain a commercial product. The dye has moderate reactivity, 20°C solubility greater than 200g / l, 1 / 1 dyeing depth: light fastness 5~6, soaping fastness 4-5, perspiration fastness 4~5, chlorine water immersion fastness Grade 4, dry rubbing fastness 4~5, wet rubbing fastness 4, ironing fastness 4, the product performance is better than traditional reactive yellow dyes.

Embodiment 3

[0030] Add 1.035 moles of cyanuric fluoride to the coupling reaction solution obtained in Example 1b), keep the temperature at 0~2°C, use 20% soda ash to keep the pH value at 6.0~6.5, add the time for 1 hour, and keep the condition for reaction 3 1 hour, add 1.15 moles of dry powdered para-ester, keep the pH at 6.0~6.5, raise the temperature to 25~30°C, keep the pH for 5 hours, and use it for concentration and purification by nanofiltration membrane. .

[0031] After the dye solution was dried, 15% of the mass ratio was added to the alkali-resistant diffusing agent JS-K and 2% of the dustproof agent for spray drying to obtain commercial dyes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| solubility (mass) | aaaaa | aaaaa |

| color fastness | aaaaa | aaaaa |

| soaping fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com