Zero-discharge water recycling process used in copper-based catalyst co-precipitation production

A copper-based catalyst, co-precipitation technology, used in catalyst activation/preparation, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

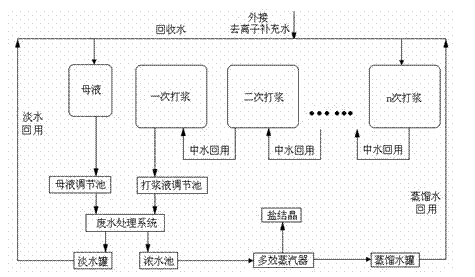

[0038] Synthetic methanol catalyst process adopts three beating process. The whole process has four concentrated water points and four concentrated waste water discharge points. The water quality of each stage is as follows:

[0039] Table 1 Water and drainage water quality in each section of the three-time beating process

[0040] .

[0041] Note: The water temperature of the inlet and outlet water is 75°C, pH=6.5-7.0.

[0042] It can be seen from Table 1 that the drainage water quality of the third beating section can reach the water quality and quantity of the secondary beating section, and it can directly enter the production line of the next production cycle after being stored in the storage tank. The drainage of the secondary beating section is also the same as the water used in the primary beating section. Therefore, the water points of the overall production line can be attributed to the raw material liquid preparation section and the third beating section; the dra...

Embodiment 2

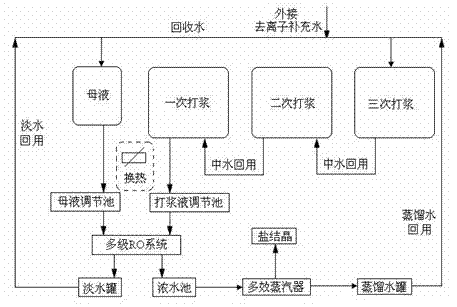

[0055] The methanol cracking hydrogen production catalyst process adopts two beating processes. The whole process has three centralized water points and three centralized wastewater discharge points. The water quality of each stage is as follows:

[0056] Table 2 Water and drainage water quality in each section of the double beating process

[0057] .

[0058] Note: The water temperature of the inlet and outlet water is 75°C, pH=6.5-7.0.

[0059] It can be seen from Table 2 that the drainage water quality of the secondary beating section cannot reach the quality and quantity of water used in the primary beating section, and the process of direct reuse to the production line cannot be adopted. At the same time, the amount of waste water is small, and direct waste water mixing and concentration treatment can be used. Comprehensive waste water: 4.5 m 3 / h,w(NaNO 3 )=0.67%.

[0060] Water balance (in hourly consumption) see Figure 4 .

[0061] Wastewater treatment ...

Embodiment 3

[0066] The gas-phase hydrogenation catalyst process adopts a three-time beating process. The whole process has four centralized water points and four centralized wastewater discharge points. The water quality of each stage is as follows:

[0067] Table 3 Water and drainage water quality in each section of the three-time beating process

[0068] .

[0069] Note: The water temperature of the inlet and outlet water is 75°C, pH=6.5-7.0.

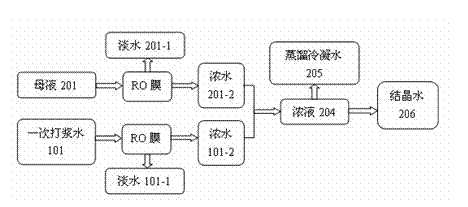

[0070] As can be seen from Table 3, the wastewater index is similar to the water quality in Example 1, and the same workshop reuse method can be used. In addition, the water volume is relatively large, and the wastewater quality is relatively stable through the adjustment of the regulating tank, which can be treated in the form of a fixed concentration ratio.

[0071] Wastewater treatment process: the wastewater from the mother liquor section and the beating section are collected in sections, the mother liquor is concentrated by one-stage rev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com