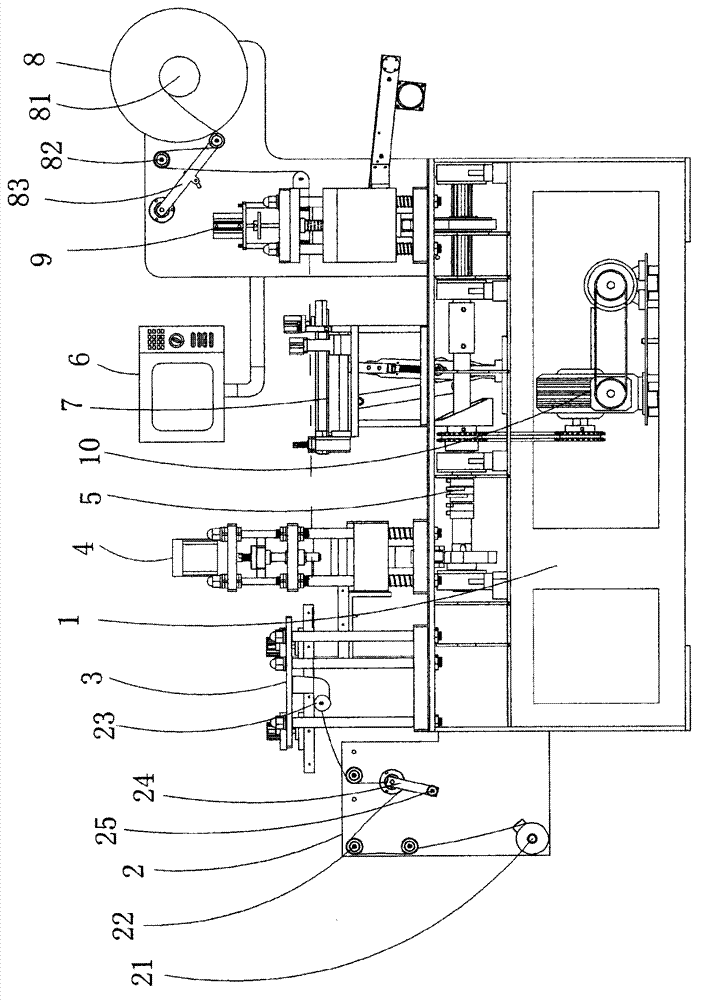

Integrated full-automatic thermoforming machine

A thermoforming machine, fully automatic technology, applied in metal processing, etc., can solve problems affecting production efficiency, mold positioning error, low processing accuracy, etc., achieve simple structure, clear positioning error, improve processing accuracy and processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

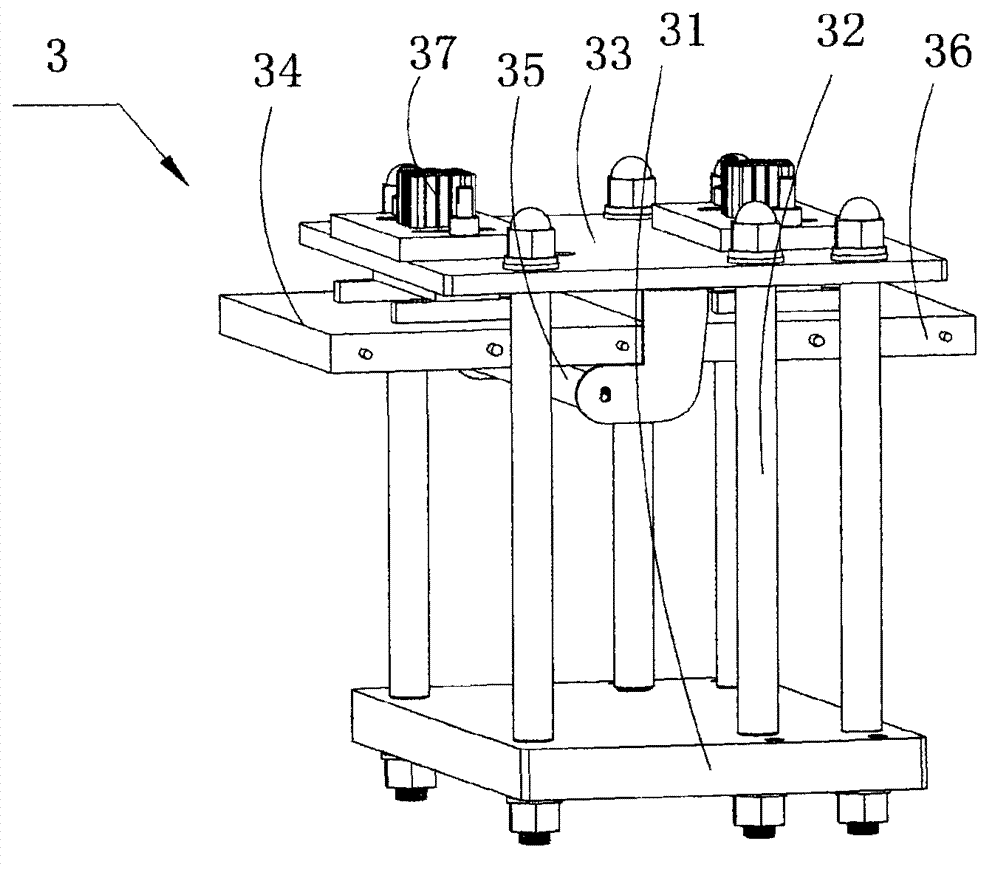

[0030] Figure 1 to Figure 6 A specific embodiment of the invention is shown in which figure 1 It is a structural schematic diagram of the present invention; figure 2 for figure 1 The specific structural schematic diagram of the main shaft transmission structure of the integrated automatic thermoforming machine shown; image 3 for figure 1 The specific structural schematic diagram of the heating structure of the integrated automatic thermoforming machine shown; Figure 4 for figure 1 The specific structural diagram of the forming and punching structure of the integrated automatic thermoforming machine shown; Figure 5 for figure 1 The specific structural schematic diagram of the sheet feeding stop structure of the integrated automatic thermoforming machine shown; Image 6 for figure 1 The specific structural schematic diagram of the punching structure of the integrated automatic thermoforming machine shown.

[0031] See Figure 1 to Figure 6 , an integrated fully au...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com