Device for drilling oblique hole in hub

A drilling device and oblique hole technology, applied in the direction of boring/drilling, positioning device, drilling/drilling equipment, etc., can solve the problems of time-consuming and human resources, high difficulty of drilling, etc., to achieve simple use, The effect of accurate drilling and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

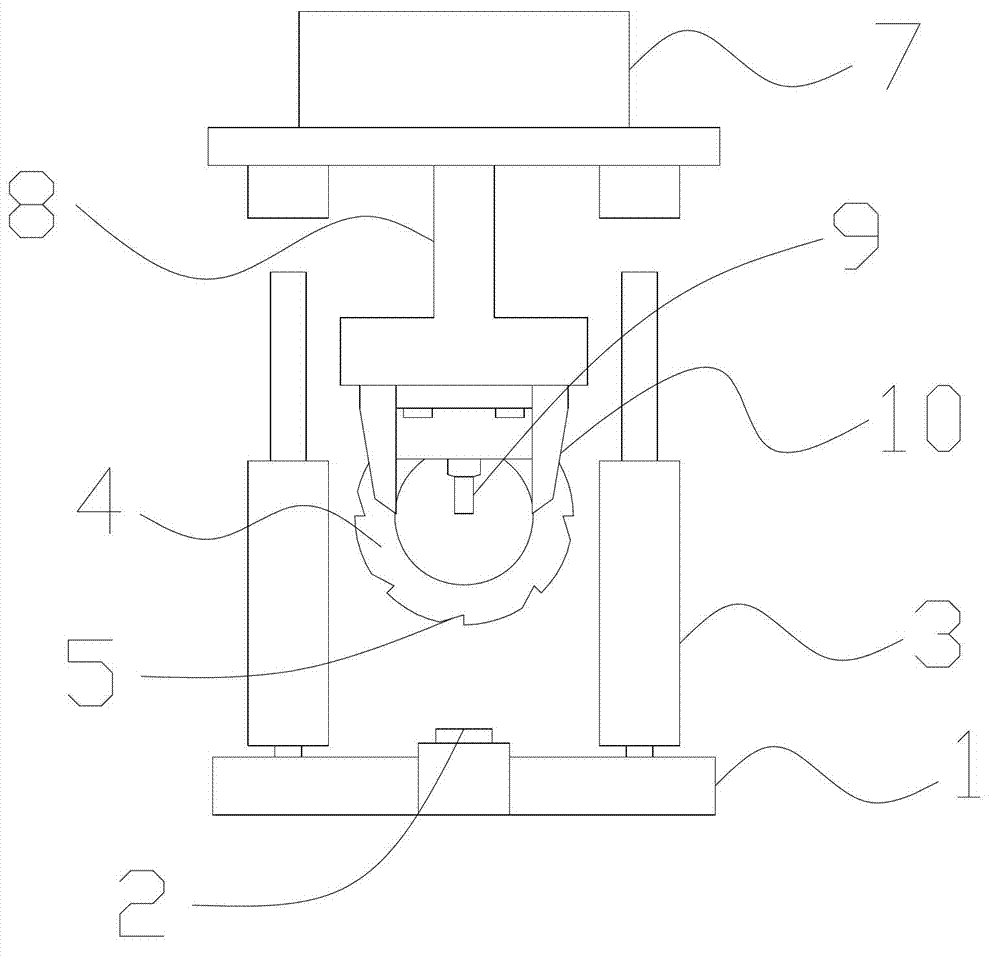

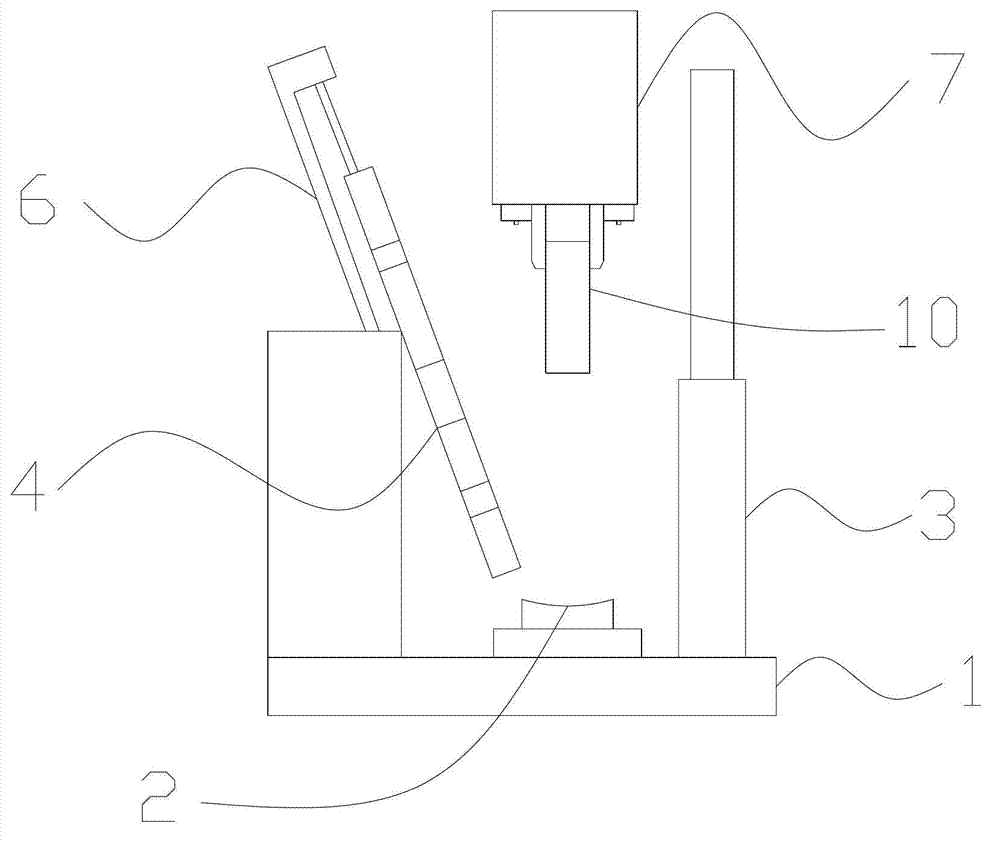

[0011] Such as figure 1 as well as figure 2 As shown, a wheel hub oblique hole drilling device includes a base 1, a fixing groove 2 is installed on the base 1, a radian is arranged on the fixing groove 2, positioning rods 3 are installed on both sides of the fixing groove 2, and a fixing groove 2 is installed on one end of the base 1. The frame 4 and the fixed frame 4 are circular structures, the fixed frame 4 is placed obliquely, the angle of the fixed frame 4 is 95°~110°, the periphery of the fixed frame 4 is provided with a groove 5, and the angle of the groove 5 can be 55° ~75°, one side of the fixed frame 4 is provided with a support rod 6, the support rod 6 is placed obliquely, the angle of the support rod 6 is 95°-110°, a connecting pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com