led lampshade mold lower template

A technology for LED lampshades and molds, which is applied in the field of templates under LED lampshade moulds. It can solve problems such as difficult control, low production efficiency, and jamming of top pillars, and achieve the effects of convenient production and improved production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

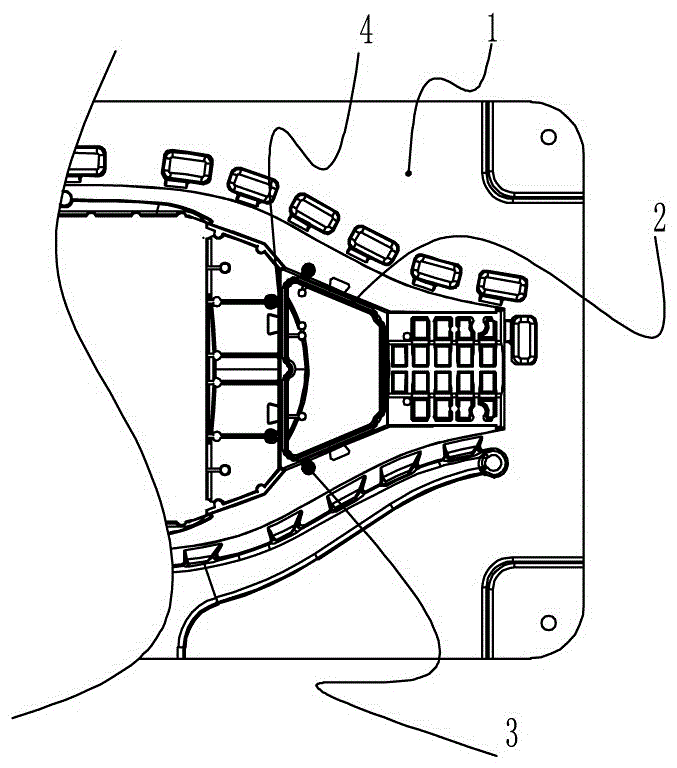

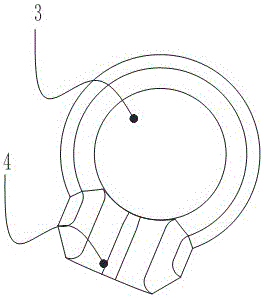

[0011] Such as figure 1 , 2 As shown: the lower template of the LED lampshade mold, including a rectangular die-casting mold 1 arranged horizontally, a sealing groove 2, and a top pillar 3 arranged around the sealing groove 2, and the top pillar 3 arranged around the sealing groove 2 has a cylindrical structure. A connecting rod 4 is provided between the top post 3 and the sealing groove 2, the length of the connecting rod 4 is 1-3 mm, and the connecting rod 4 and the top post 3 are integral structures.

[0012] In the present invention, the structure of the top pillar 3 which is arranged close to the periphery of the sealing groove 2 is changed from a circular arc shape to a cylindrical shape, and the distance between the top pillar 3 and the sealing groove 2 is increased. During die-casting and secondary processing, The phenomenon of interference between the top post 3 and the sealing groove 2 is prevented. For example: to avoid the lack of material in the top column of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com