Seedling-raising disk substrate cylinder-type punching and indenting device

A seedling tray and drum type technology is applied in the field of a seedling tray substrate drum type hole punching machine device, which can solve the problems of heavy drum weight and the like, and achieve the effects of weight reduction, simple processing and good hole pressing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with drawings and embodiments.

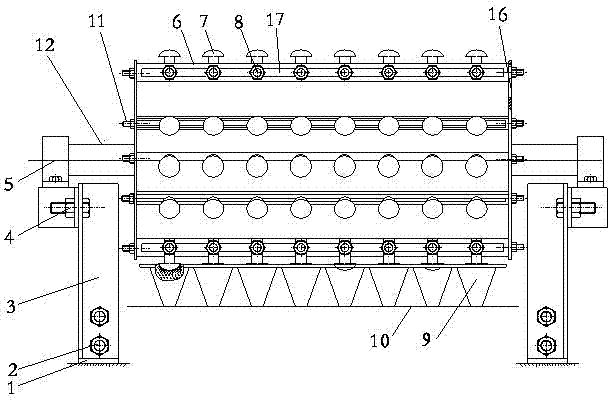

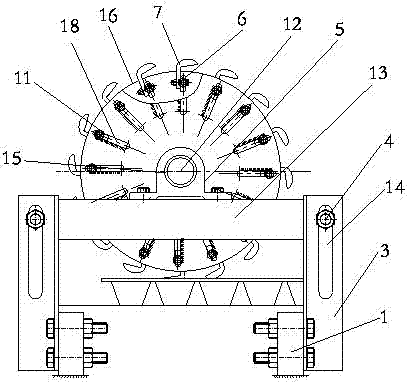

[0023] see figure 1 and figure 2 , the seedling tray matrix drum type punching and pressing device comprises a drum 16, a drum rotating shaft 12, a bearing seat 5, a bearing frame 13 and a support 3, the drum rotating shaft 12 is coaxially connected with the drum 16, and the cylindrical outer surface of the drum 16 is equal to Spokes 6 parallel to the drum rotating shaft 12 are arranged at a distance, and the two ends of the spokes 6 are provided with an axial adjustment through groove 17 along the axial direction of the drum rotating shaft 12 on the spokes 6, and the acupoint pressing head 7 formed by a circular arc passes through the shaft. The spacing adjustment bolts 8 are equally spaced in the axial adjustment slots 17; the two ends of the drum 16 are provided with radial adjustment slots 18 along its radial direction, and the two ends of the spokes 6 are fixed b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com