Device for testing gas flow field structure of kerf in laser cutting process

A test device and laser cutting technology, applied in the field of laser processing, can solve the problems of drastic changes in gas flow field structure and difficult detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the drawings and specific embodiments:

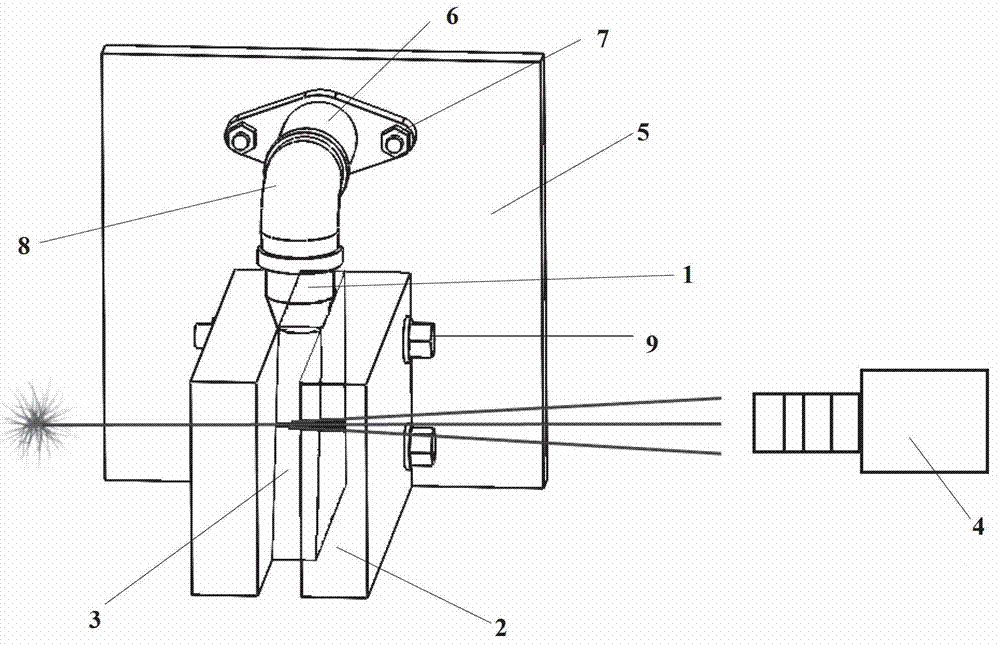

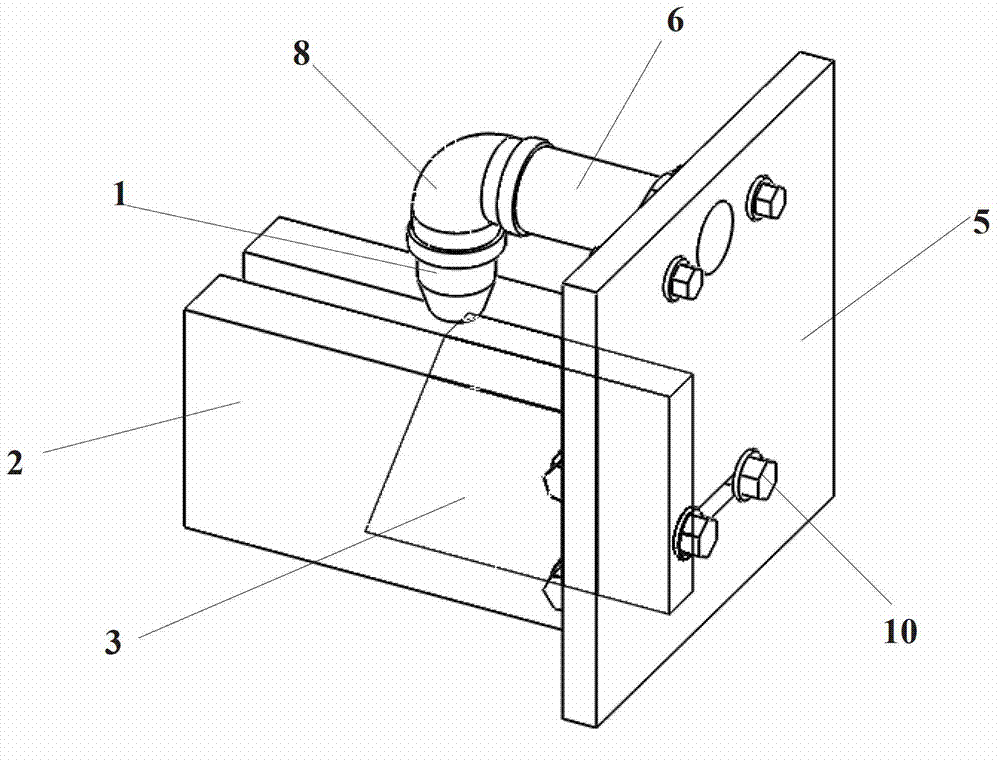

[0023] Such as figure 1 with figure 2 , A testing device for the gas flow field structure of slitting in the laser cutting process, including: a gas injection module with a nozzle 1, two pieces of plexiglass arranged in parallel 2, a thin metal plate with a bevel 3, a CCD camera 4, Support plate 5; the inner walls of the two opposing sides of the organic glass 2 are coated with viscous fluid.

[0024] Wherein, the beveled metal sheet 3 is fixed between the opposite surfaces of two pieces of organic glass 2; the two pieces of organic glass 2 and the gas injection module are fixed on the supporting plate 5; the nozzle 1 is located on the two pieces of organic glass. The top of the glass corresponds to the oblique angle of the thin metal plate 3. The CCD camera 4 is located on the outside of any organic glass and is arranged in parallel with the organic glass.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com